Traxxas 59076-1 User Manual

Page 38

38 • SLAYER PRO 4X4

ADVANCED TUNING ADJUSTMENTS

Tuning The Sealed Gear Differentials

Slayer Pro 4x4’s front and rear gear differentials allow the left and right

wheels to spin at different speeds while turning so that the tires do

not scuff or skid. This decreases the turning radius and increases

steering performance.

The performance of the differentials can be tuned for different driving

conditions and performance requirements. The differentials are filled with

silicone differential fluid, and are sealed to maintain consistent long-term

performance. Changing the oil in the differential with either lower or higher

viscosity oil will vary the performance characteristics of the differentials.

Changing to a higher viscosity oil in the differential will reduce the tendency

for engine power to be transferred to the wheel with the least traction. You

may notice this when making sharp turns on slick surfaces. The unloaded

wheels on the inside of the turn have the least traction and tend to spin up

to extremely high rpms. Higher viscosity (thicker) oil causes the differential

to act like a limited-slip differential, distributing more equal power to the

left and right wheels. Slayer Pro 4x4 will generally benefit from higher

viscosity oil when climbing, rock crawling, or racing on low traction surfaces.

Note: Heavier oil will allow power to be transferred even with one or more

tires off the ground. This can make the vehicle more likely to overturn.

From the factory, both the differentials are filled with SAE 30,000W viscosity

silicone oil. Only use silicone oil in the differentials. Traxxas sells SAE

10,000W and SAE 50,000W viscosity oil (see your parts list). The differentials

have to be removed from the vehicle and disassembled to change/replace

oil.

SHOCK TUNING

Shock Pistons

The shock pistons can be replaced with the available optional pistons to

vary the amount of damping. Optional pistons with bypass holes that are

smaller (#2 or #3) than the factory installed stock pistons can be used to

increase damping. From the factory, Slayer Pro 4x4 is equipped with #1

pistons in the front and rear.

Shock disassembly

The shocks must be removed from the vehicle and disassembled to change

the pistons. Use the shock exploded views included with the model to aid in

the assembly process.

1. Remove the spring and lower spring retainer from the shock.

2. Remove the shock cap (A) and empty the shock body of shock oil.

3. Remove the lower cap (B) and the X-ring from the shock body.

4. Use side cutters to grip the shock shaft just above the rod end (C).

Remove the rod end from the shock shaft using the suspension multi

tool (C).

5. Remove the shock shaft with piston

from the shock body out through the

top of the shock body.

Shock assembly

1. Replace the stock piston with desired

optional piston. Be careful not to lose

the small washer located below the

piston.

2. Position the new piston onto the

shock shaft above the small washer.

Grip the threads of the shaft with

side cutters or needlenose pliers

and tighten the nut with the 4-way

wrench to secure the assembly.

3. Insert the shock shaft assembly

through the shock body until the

piston bottoms out.

4. Lubricate the shaft and X-ring with

silicone oil.

5. Install the X-ring over the shaft and

into the bore of the shock body.

6. Install the lower cap using the

suspension multi-tool (B).

7. Slide the bump stop onto the shaft.

8. Grip the shaft close to the threads

with needle nose pliers or side

cutters and thread the rod end onto

the shock shaft until the rod end

bottoms out (C).

9. Fill the shock with new silicone shock oil up

to the top of the shock body. Slowly move

the piston up and down (always keeping it

submerged in oil) to release the air bubbles.

Let the shock sit for a few minutes to allow

any remaining air bubbles to surface.

10. Slowly thread the upper cap with the

installed shock bladder onto the shock body

with the suspension multi-tool (A). The excess

oil will bleed out of the small hole in the shock cap. Tighten the shock

cap until snug. Use the included steel shock wrench to hold onto shock

body while tightening.

11. Reinstall the spring and lower retainer.

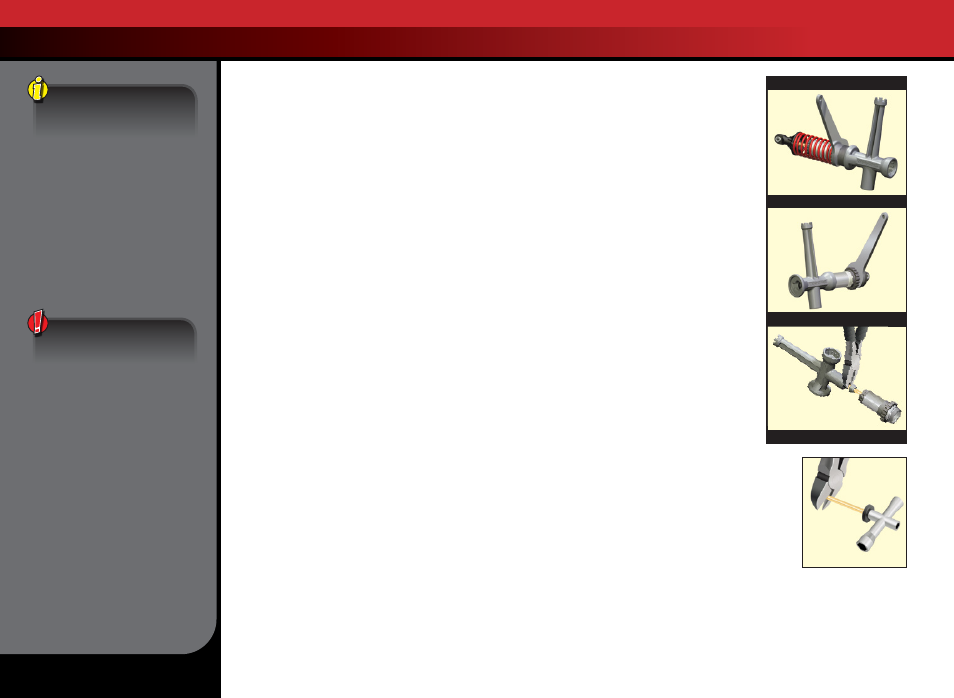

A. Tighten/Loosen Upper Cap

C. Remove/Install Rod End

B. Tighten/Loosen Lower Cap

Multi-tool Shock Functions

Piston Installation/Removal

Never slide the threads on

the shock rod past the X-ring

seal when it is installed and

compressed by the bottom

cap of the shock. Doing so will

damage the seal and cause

shock oil to leak.

Use higher viscosity

(thicker) diff oil for:

• More power to the wheels

with the most traction.

• Racing on low-traction

smooth surfaces.

• Better performance for

climbing on uneven terrain.

Using lower viscosity

(thinner) diff oil for:

• More power to the wheels

with least traction.

• Racing on low-traction

rough surfaces.