Slant/Fin EC-20 Installation User Manual

Page 15

EUTECTIC EC-20

15

BURNER DATA - FOR RIELLO BURNERS SHIPPED WITH BOILERS ONLY

† Air shutter and head settings shown are approximate ONLY. See START-UP page 7. Seal joint between flange and air tube with a suitable high

temperature sealant, if joint was not sealed at factory.

It is suggested that due to the positive pressure observed in the chamber that the air tube hole and any other passages of the flue gas leakages

be sealed to avoid combustion gas fumes from leaking into the boiler room.

5/32” or 4 mm

13/64” or 5 mm

13

/64”

5 mm

D6003

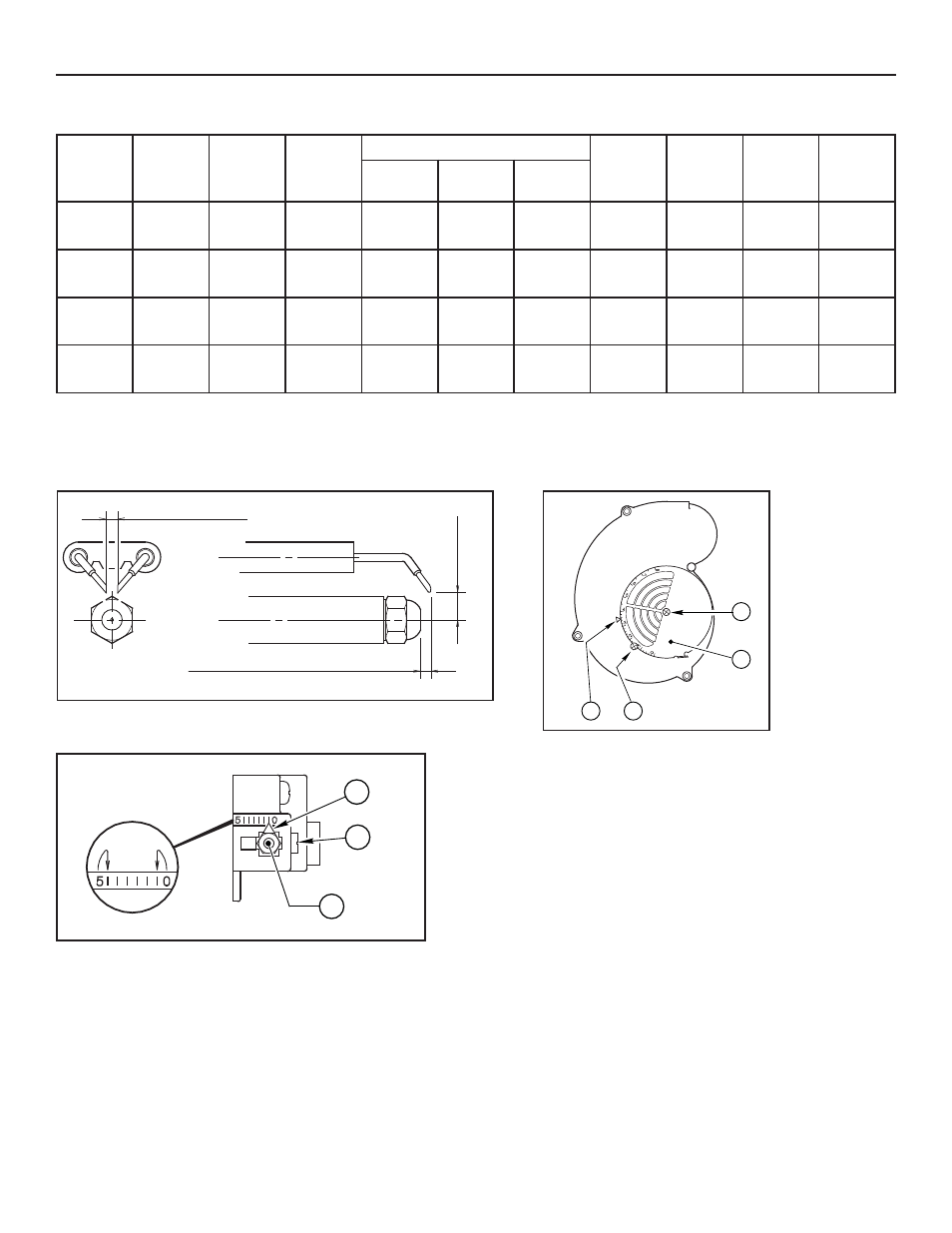

Figure 6. Riello 40 Series. Model F-10 Electrode Setting

TURBULATOR SETTING

A) Loosen NUT (1), then turn SCREW (2) until the INDEX

MARKER (3) is aligned with the correct index number as per the

Burner Set-up chart, on page 12.

B) Retighten the RETAINING NUT (1).

NOTE: Zero and five are scale indicators only. From left to right,

the first line is 5 and the last line 0.

SETTING THE AIR ADJUSTMENT PLATE

A) Regulation of the combustion air flow is made by

adjustment of the manual AIR ADJUSTMENT PLATE

(1) after loosening the FIXING SCREWS (2 & 3).

The initial setting of the air adjustment plate should be

made according to Column 5 in the Burner Set-up Chart.

B) The proper number on the manual AIR ADJUSTMENT

PLATE (1) should line up with the SETTING INDICATOR

(4) on the fan housing cover. Once set, the air adjustment

plate should be secured in place by tightening SCREWS

2 and 3.

C) The final position of the air adjustment plate will vary on

each installation. Use instruments to establish the proper

settings for maximum CO2 and a smoke reading of zero.

NOTE

: Variations in flue gas, smoke, CO2 and temperature

readings may be experienced when the burner cover is put

in place. Therefore, the burner cover must be in place when

making the final combustion instrument readings, to ensure

proper test results.

3

2

1

D5997

Figure 7. Riello 40 Series. Model F-10 Turbulator Setting

D5231

2

1

3

4

Figure 8. Riello 40 Series. Model F-10

Setting the Air Adjustment Plate

Boiler

Model

Burner

Model

Blast

Tube

Firing

Rate

GPH

Nozzles

Oil Pump

(PSIG)

Approx.

Head

Setting †

Approx.

Air

Setting †

Burner

Insertion

Depth

Size

GPH

Angle &

Type

MFR.

EC-25

F-10

Long

1.55

1.25

60˚ B

Hago

158

1.5

2.8

7"

EC-26

F-10

Long

1.9

1.5

45˚ B

Hago

160

2.0

4.0

7"

EC-27

F-10

Long

2.25

1.75

45˚ B

Hago

165

4.0

4.5

9.5"

EC-28

F-10

Long

2.5

2.0

45˚ B

Delavan

155

5.0

4.5

9.5"