Slant/Fin L-Series User Manual

Page 3

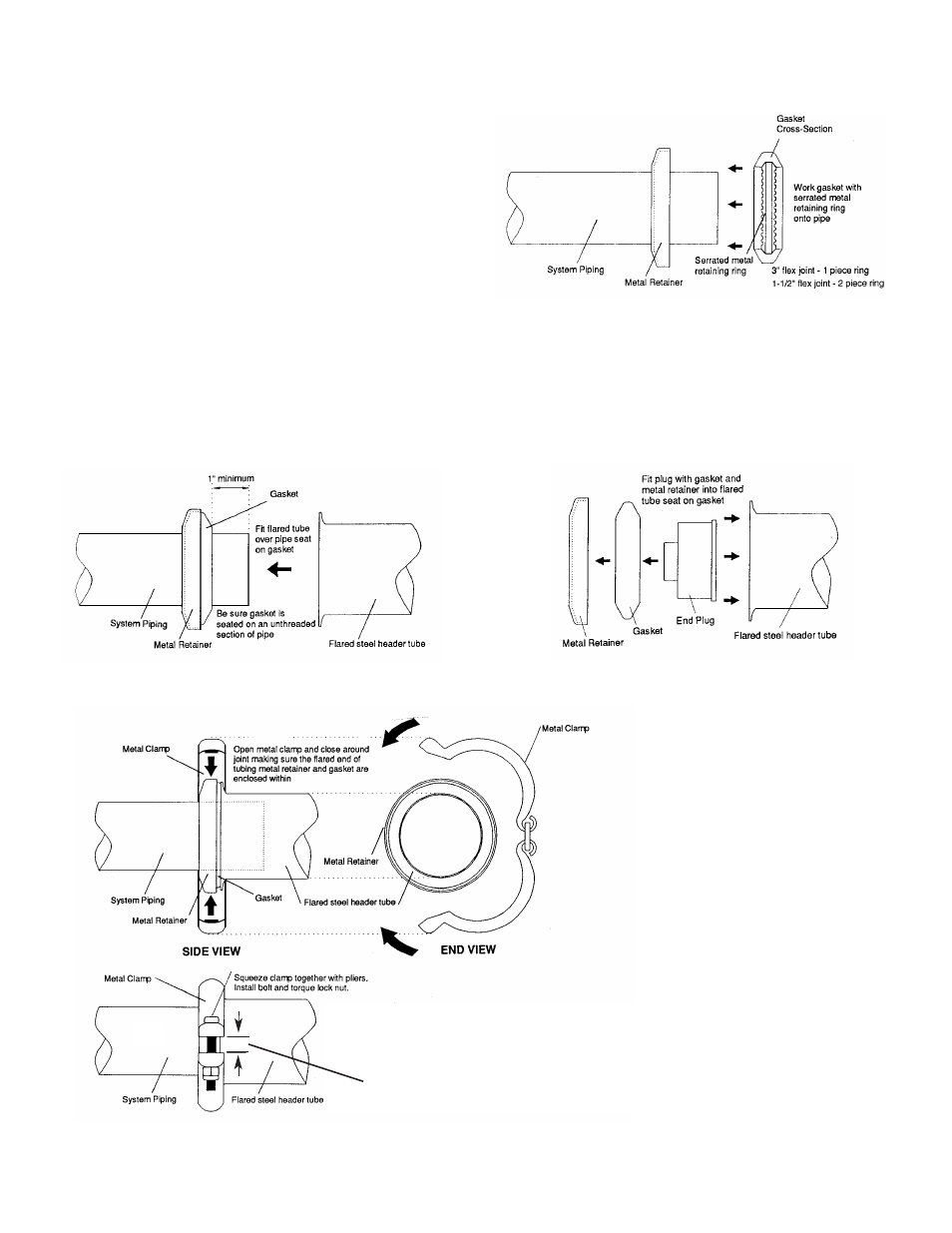

Caravan Flex Joint Assembly Instructions

1. Slip the metal retainer on the system piping with the larger

diameter side facing the end of the pipe to be joined. The

3" flex joint has a single piece serrated metal retaining

ring. This retaining ring should be seated in the recess in

the inner diameter of the gasket with its mounting tabs

overlapping slightly where the ring splits. The 1-1/2" flex

joint has a 2 piece serrated retaining ring that must be

installed in the inner recess of the gasket with its ends

butting.

Work the gasket with the serrated metal retaining ring onto the pipe. When installing the gasket be sure the retaining rings seat

properly around the pipe. On the 1-1/2" flex joint install the bottom half of the gasket first leaving the other half of the retaining ring

free at the top. Then stretch the top of the gasket with the ring over the top of the pipe. When installing the gaskets if a lubricant

is needed, use a soap and water solution only. DO NOT use any oil based lubricants.

2. The gasket must be fully seated in the metal retainer (press together with pliers if necessary). BE SURE THE GASKET IS

SEATED ON AN UNTHREADED SECTION OF PIPE AT LEAST 1" FROM THE END. Slip the flared end of the Slant/Fin

header tube over the pipe and seat against the gasket. Follow illustration a or b for cast end cap or piping.

a)

b)

3. Open hinged metal clamp and slip over joint. Be sure that the flared end of the steel tubing, the retainer ring and the gasket

are enclosed within the clamp.

4. Install the bolt and lock nut and tighten the lock nut to

the following torque values: 1-1/2" flex joint is 140-160

inch-pounds, 3" flex joint is 220-240 inch-pounds.

NOTE:

On 3” schedule 40 pipe, spacing between clamps is

approximately 3/8” when properly torqued.

On 1-1/2" schedule 40 pipe, spacing between clamps

is approximately 1/4" when properly torqued.