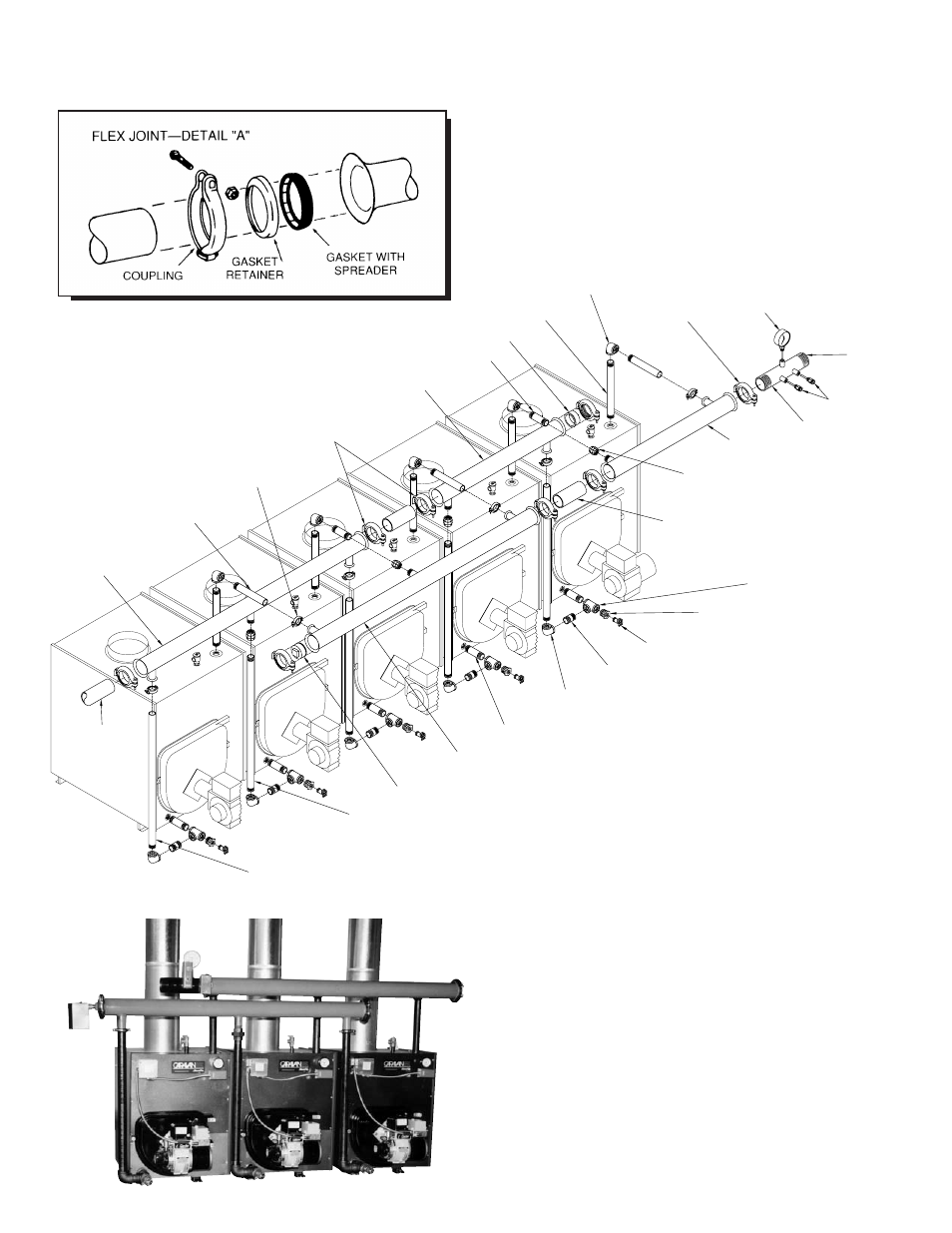

Factory supply and return header assembly — oil – Slant/Fin L-Series User Manual

Page 2

NOTE:

Shown reverse return (Preferred). For direct

return, header assembly piping connections

may be made at the same end of the boiler

bank, not as shown. Some governing agen-

cies do not allow compression type couplings.

Consult your local code requirements.

3'' RETURN HEADER

WITH 1

1

/

2

'' STUBS

(3 MODULE)

* 3'' BUILDING

PIPING

(BY OTHERS)

1

1

/

2

'' X 34'' SQUARE NIPPLE

1

1

/

2

'' X 30'' NIPPLE

CAST END CAP

WITH

3

/

4

'' TAPPING.

SUPPLY OR RETURN.

FOR USE WITH LWCO.

3'' SUPPLY HEADER

WITH 1

1

/

2

'' STUBS

(3 MODULE)

1

1

/

2

'' X 4'' NIPPLE

3'' PIPE X 20''

(BY OTHERS)

1

1

/

2

'' UNION

1

1

/

2

'' X 1

1

/

2

'' X 1

1

/

2

'' TEE

1

1

/

2

'' X

3

/

4

'' BUSHING

3

/

4

'' DRAIN VALVE

1

1

/

2

'' X CLOSE NIPPLE

1

1

/

2

'' ELBOW

3'' SUPPLY HEADER

WITH 1

1

/

2

'' STUBS

(2 MODULE)

*

3'' BUILDIING PIPE

CONNECTION

1

/

2

'' PRESSURE

TEMPERATURE

GAUGE

1

/

2

'' WELLS

3'' FLEX JOINT

(SEE DETAIL "A")

1

1

/

2

'' ELBOW

1

1

/

2

'' X 15'' NIPPLE

CAST END CAP

3'' RETURN HEADER

WITH 1

1

/

2

'' STUBS

(2 MODULE)

3'' FLEX JOINTS

(SEE DETAIL "A")

1

1

/

2

'' X 8'' SQUARE NIPPLE

1

1

/

2

'' FLEX JOINT

(SEE DETAIL "A")

1

1

/

2

'' X 4'' NIPPLE

CONTROL HEADER

3'' x

1

/

2

'' x

1

/

2

'' x

1

/

2

''

FACTORY SUPPLY AND RETURN HEADER ASSEMBLY — OIL

* Building piping must be rigidly secured so it cannot

move where connected to headers.