Controls, The boiler staging concept, Control system selection – Slant/Fin Gas Hot Water User Manual

Page 11

10

20

30

40

50

60

70

1/4

.364

32

22

18

15

14

12

11

3/8

.493

72

49

40

34

30

27

25

1/2

.622

132

92

73

63

56

50

46

3/4

.824

278

190

152

130

115

105

96

1

1.049

520

350

285

245

215

195

180

1 1/4

1.380

1,050

730

590

500

440

400

370

1 1/2

1.610

1,600

1,100

890

760

670

610

560

2

2.067

3,050

2,100

1,650

1,450

1,270

1,150

1,050

2 1/2

2.469

4,800

3,300

2,700

2,300

2,000

1,850

1,700

3

3.068

8,500

5,900

4,700

4,100

3,600

3,250

3,000

4

4.026

17,500

12,000

9,700

8,300

7,400

6,800

6,200

80

90

100

125

150

175

200

1/4

.364

11

10

9

8

8

7

6

3/8

.493

23

22

21

18

17

15

14

1/2

.622

43

40

38

34

31

28

26

3/4

.824

90

84

79

72

64

59

55

1

1.049

170

160

150

130

120

110

100

1 1/4

1.380

350

320

305

275

250

225

210

1 1/2

1.610

530

490

460

410

380

350

320

2

2.067

990

930

870

780

710

650

610

2 1/2

2.469

1,600

1,500

1,400

1,250

1,130

1,050

980

3

3.068

2,800

2,600

2,500

2,200

2,000

1,850

1,700

4

4.026

5,800

5,400

5,100

4,500

4,100

3,800

3,500

11

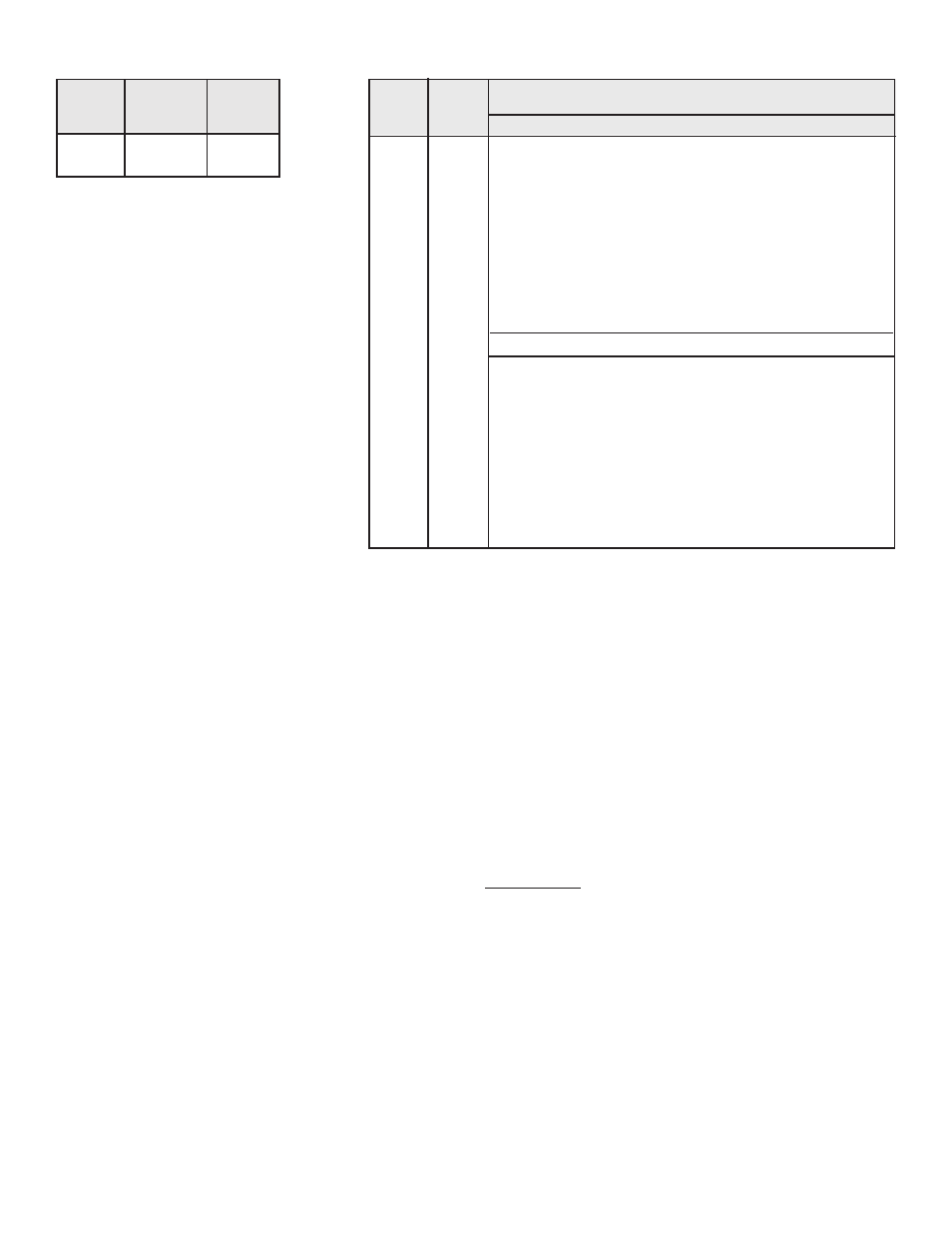

Table 5. Characteristics of various fuel gases

Table 6. Gas main sizing guide

Natural

1000 Btu

1.00

Propane

2500 Btu

1.10

Type

of Gas

Heating

Valve*†

Flow

Correction

Factor

* per cubic foot

† Consult fuel supplier for actual BTU value.

Nominal

Iron Pipe

Size

Inches

Internal

Diameter

Inches

Equivalent

Length of Pipe, Feet

Maximum capacity of pipe in cubic

feet of gas per hour for gas pres-

sures of 0.5 psig or less and a

pressure drop of 0.3 inch water

column (based on a 0.60 specific

gravity gas).

CONTROLS

THE BOILER STAGING CONCEPT

The heart of the Caravan boiler plant is a temperature-actuated

control system that automatically stages only those boiler

modules needed to meet the heating demand in a given period,

thereby conserving fuel.

In a staging control system, each stage ordinarily activates one

boiler module. With appropriate wiring, multiple modules can be

grouped within a stage.

During a fluctuation in heating requirements, a large central boiler

cycles on and off to match heat output to building demand. A

staged modular boiler system, on the other hand, will energize

only as many modules as the system load requires. Only one

stage cycles at a time. The other stages remain off or operate

continuously, thereby performing at peak efficiency. For example,

in a 10 module boiler system, with the heating load at 61% of

capacity, six of the modules operate continuously at peak

efficiency. Fractional heating requirements are supplied by the

seventh "cycling" module, while the remaining three modules are

"off." This is in contrast to a single large central boiler that simply

cycles on and off, resulting in lower efficiency.

Over-sizing is a major factor in poor system efficiency. Most of the

time a single central boiler is oversized. Historical data shows

that many single central boilers are considerably oversized even

at the outdoor temperature for which they were designed.

Modular boiler systems are not oversized by more than a portion

of one module, regardless of the load.

The Caravan control system automatically compensates for

seasonal temperature changes. It energizes more or fewer

modules depending on changes of outside temperature, system

water temperature, or both. Modules save energy by operating in

long cycles at full-rated output and maximum efficiency.

CONTROL SYSTEM SELECTION

Slant/Fin offers two controls to step fire a hot water Caravan sys-

tem. The SC-3 and SC-9 controls fulfill a wide range of applica-

tions. They control the boiler system and are not intended to be

the sole building temperature control. They do not replace zoning

the system or the thermostats that control these zones.

SC-3 Control

The SC-3 control allows up to 3 stages in a Caravan system.

Generally each stage controls 1 module. However, it is possible to

have more than 1 module activated with each stage.

Standard programmable features include: system activation or

de-activation based on outdoor temperature; minimum target

supply water temperature; adjustable design target supply water

temperature; adjustable delay between stages; adjustable

outdoor temperature and indoor design temperatures.

The view menu on the control includes error messages, actual

outdoor air temperature, actual supply water temperature,

target supply water temperature and running time for each stage.