Page 4, Figure 3 – Sigtronics S-A-F-E Installation Instructions User Manual

Page 4

user then presses the PTT button on his headset ear cup

to talk on the intercom. The advantage of this method

is that it eliminates having to mount and wire in addi-

tional PTT buttons for the jump seats. Note, however,

most departments prefer to have all the headsets on the

vehicle(s) the same so that any headset can be used in

any position. The headsets with intercom PTT switches

on them cannot easily be used in a position that has

radio transmit capability such as the Driver or Officer

position.

Sigtronics provides two ways to mount the headset jacks for

the SAFE unit:

1. Mount the jacks in the supplied blue jack boxes.

Advantages:

a) Little or no “behind the panel” space required.

b) No vehicle panel thickness limitation.

c) No large holes are required to be drilled - a real advan-

tage on vehicles with thick metal panels.

d) Complete electrical isolation of the jacks from the vehi-

cles chassis, because the jack box is fabricated out of

non conductive high impact plastic.

2. Mount the jacks directly on the vehicle with a “through the

panel” mounting scheme. Advantages:

a) Smaller space requirement. (Only slightly larger than

the jack itself).

b) Only one hole to drill per jack (1/2 inch).

c) Most of jack is behind panel and out of the way.

Sigtronics recommends that you use the jack box mounting

method, but either approach can be used as well as a com-

bination of both.

If required, additional headset jacks, PTT switches, mounting

boxes, and hardware are available through your Sigtronics

dealer.

Splash Cover (optional):

If a jack is to be mounted outside the vehicle (ie. on or near

a fire engines pump panel), a splash cover (purchased sepa-

rately) should be used to keep excess moisture out of the jack

when it is not in use. On other positions, where the headset

is always plugged in, a splash cover is not required.

Jack Box Mounting:

Set the jack box on the mounting surface in the selected area

and mount with two of the hex head self drilling screws. For

most applications* these screws can be installed with no

pre drilling. Just power in the screws with a standard electric

driver with a 5/16” hex bit.

* No pre drilling required for aluminum and steel. 1/8” inch pilot

hole will still be required with some stainless steels.

For most installations the wiring for the headset jack will

come out the back of the jack box. A hole is already provided

in the jack box for this purpose. Of course, you will also have

to drill a similar hole into the vehicle. Use a 5/16 inch drill for

this.

Alternately, the wire can come out of the side of the jack box

if desired. You will have to drill the hole where required. Use

a 5/16 inch drill. Rubber wire grommets are provided for the

wire going through the jack box hole.

Through the Panel Mounting:

For direct mounting of headset jacks on the vehicle panel you

will need to remove the jack from the jack box cover with a

1/2 inch wrench. For normal jack mounting (no splash cover),

the maximum panel thickness is 0.10 inches or a little less

than 1/8 of an inch. If you need the splash cover (optional),

the maximum panel thickness is 0.062 inches or 1/16 of an

inch. NOTE: Longer headset jacks that can accommodate

thicker panels are available from your Sigtronics dealer (order

part number 100418 - maximum panel thickness 0.155” with

splash cover and 0.195” without).

Mounting on the panel requires that you insert the jack

from the back of the panel. Test jack(s) for clearance and fit.

Leave room behind - the jack expands when headset plug is

inserted. Make sure the back of the jack does not interfere

with any moving parts of the vehicle.

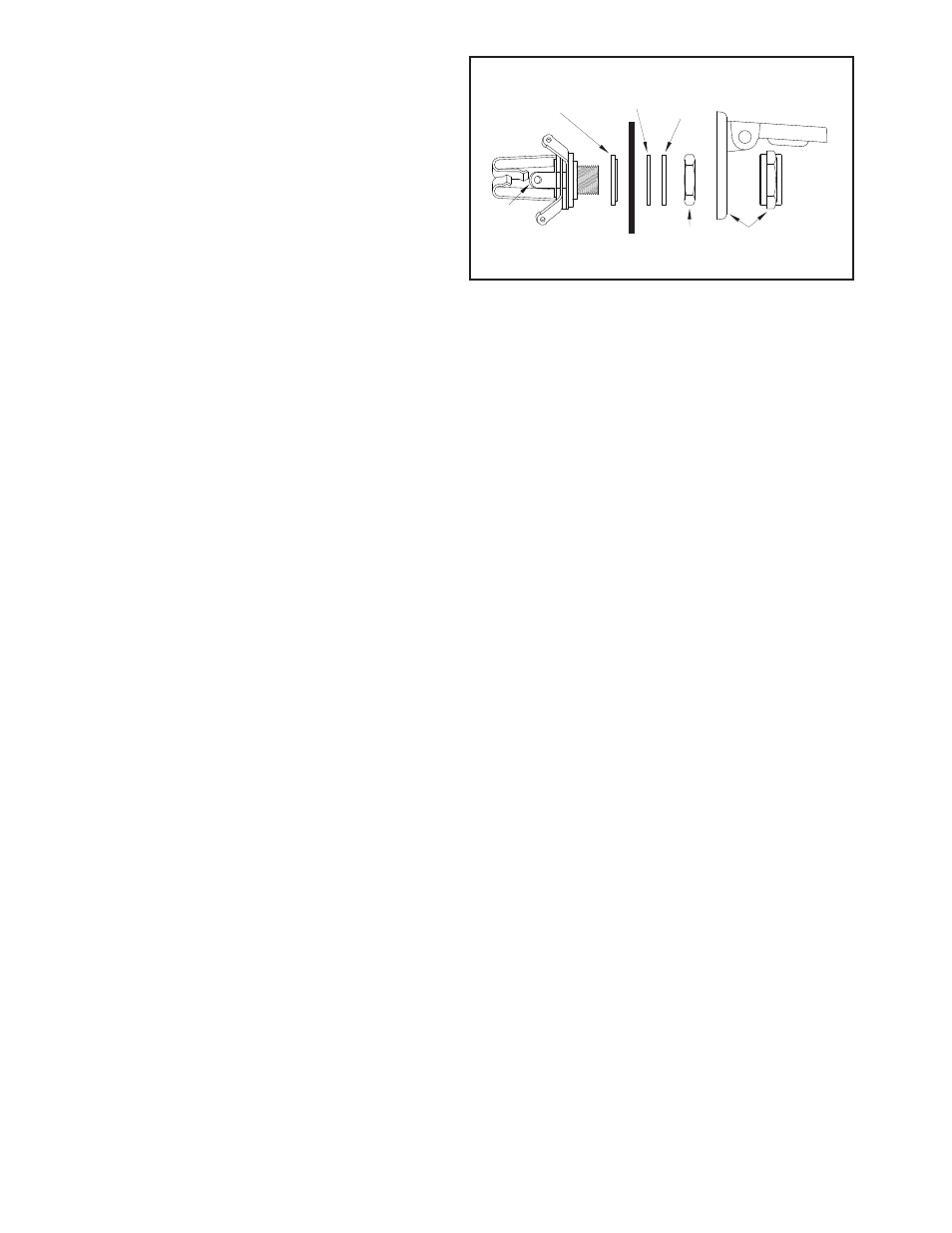

Drill a 1/2 inch hole in the panel. Install jack with mounting

washers and nut as in Figure 3. Both jack insulating washers

must be used. The Jacks have to be insulated from mount-

ing spot to minimize electrical noise getting into intercom

system. No need to tighten the jack now. You may have to

remove the jack to connect the wires.

PTT Switch Installation:

In order for the Driver or Officer positions to transmit on the

radio, they will each need a Push-To-Talk (PTT) switch.

The PTT switches should be placed within easy reach of the

users. It is also helpful if they can be easily seen by the users.

The PTT switches can be mounted in the blue ptt mounting

boxes or directly into a panel. If using the ptt boxes, set the

box on the mounting surface in the selected area and mount

with two of the hex head self drilling screws. For most appli-

cations* these screws can be installed with no pre drilling.

Just power in the screws with a standard electric driver with

a 5/16” hex bit. * No pre drilling required for aluminum and steel.

1/8” inch pilot hole will still be required with some stainless steels.

page 4

BARREL

SHOULDER

INSULATING

WASHER

HEADSET JACK

TIP

FLAT

INSULATING

WASHER

FLAT

METAL

WASHER

VEHICLE

PANEL

NUT –

OR

– SPLASH COVER AND NUT

FIGURE 3

RING