Quick service guide, Uick service guide, Operation 3.5. quick service guide – CMA Dishmachines CMA-180UC User Manual

Page 15

Operation

3.5.

Quick service guide

MODEL CMA-180UC INSTALLATION & OPERATION MANUAL Rev. 1.13

Page

14

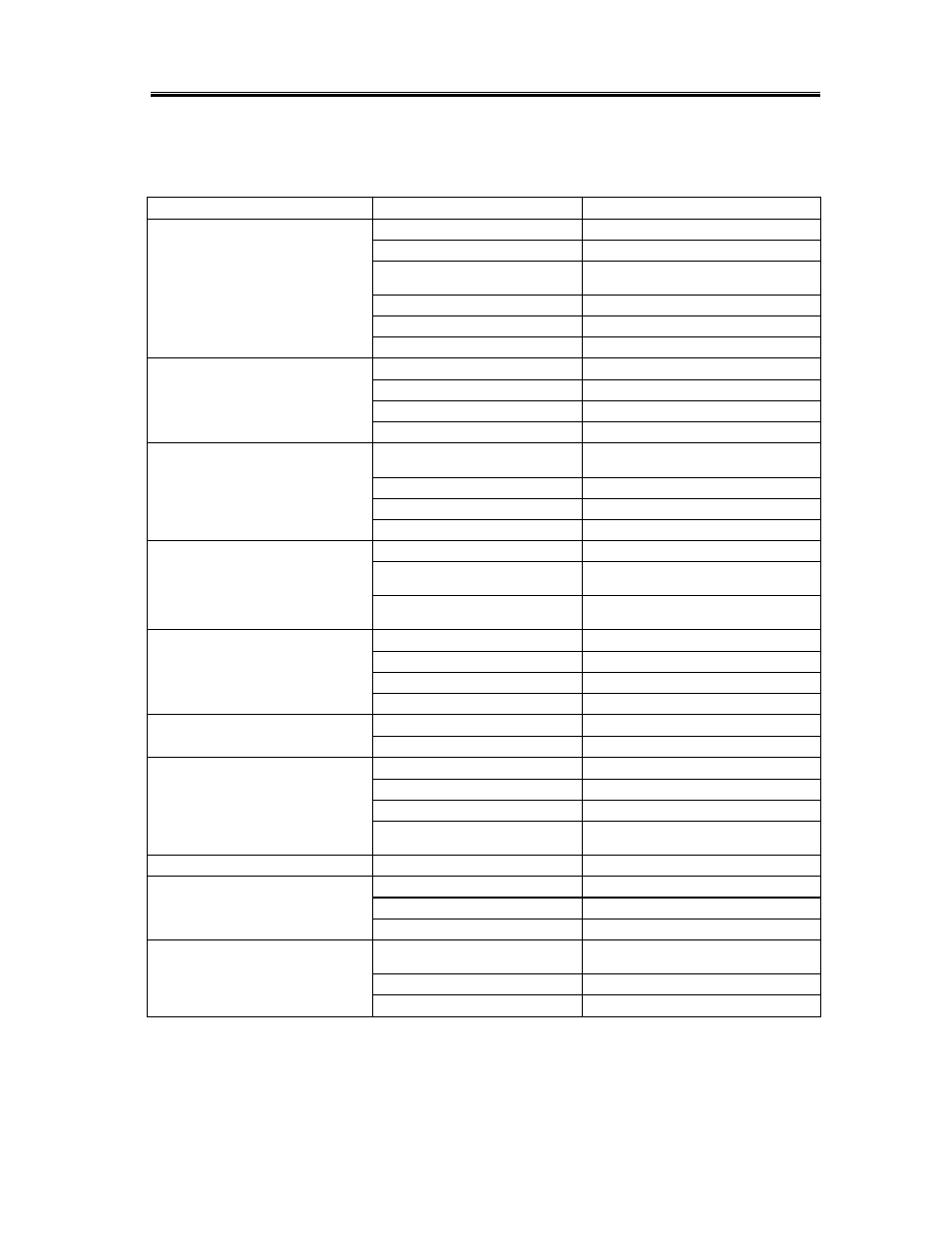

MODEL: CMA 180UC HIGH TEMP UNDER COUNTER

TECHNICAL ISSUE

CAUSE

SOLUTION

Pressure regulator is not set properly Set regulator to 18-20 psi

Faulty rinse micro switch

Replace micro switch, P/N 00411.00

Scrap trap over flows

Drain hose elevated too high

Must be lowered to goose neck level

Obstruction in drain hose

Check hose & clean

Scrap exit screen

Clean exit screen

Faulty drain pump

Replace pump, P/N 15503.00

Machine not level

Adjust machine legs to level

Machine is leaning forward

Adjust machine legs to level

Door leaks

Wash arm end cap missing

Replace end cap, P/N 00308.20

Door gasket

Replace gasket, P/N 14506.60

Loose wire at display, board or

transformer

Secure connectors

Thermometer failure

Faulty temperature sensing wire

Correct, replace, P/N 03202.66

Faulty temperature sensing unit

Replace unit, P/N 03203.00

Faulty transformer

Replace transformer, P/N 03202.60

Scaled heating element

Clean scale from heater

Rinse water temperature low /high

Booster heater’s thermostat not

properly set

Adjust thermostat

Incoming water temperature to

booster heater below 140 F

Adjust external water heater in the facility

Loose lead connections

Check and crimp connectors

Pump motor not running

Faulty # 3 micro switch

Replace micro switch, P/N 00411.00

Faulty contactor

Replace contactor, P/N 15504.00

Faulty wash pump motor

Replace wash pump motor, P/N 00201.00

Pump motor runs continuously

Faulty # 3 micro switch

Replace micro switch, P/N 00411.00

Faulty contactor

Replace contactor, P/N015504.00

Water regulator not adjusted properly Adjust regulator to 18-20 PSI

Low water pressure at the final rinse

Clogged final rinse spray jets

Clean jets

Missing final rinse spray end cap

Replace end cap, P/N 00308.17

Low incoming water pressure from

facility

Increase pressure to 18-20 psi

Scrap trap overflows over night

Faulty water solenoid diaphragm

Clean or replace diaphragm, P/N 00706.00

Low wash or rinse water temp.

Check temperature settings

Poor cleaning results

Wash arm bearing or jets

Clean bearing and arm jets

Rinse arm bearing or jets

Clean bearing and arm jets

Tank discharge screen dirty

Clean screen

Wash tank will not drain.

Drain valve not operating

Check power to drain valve

Drain valve faulty

Replace Drain valve, P/N 04103.00