Maintenance, Changing the gobos, Lubrification – OmniSistem PR Pilot 300 User Manual

Page 8

MAINTENANCE

If the projector’s lens becomes damaged or broken it should be replaced. If the lamp becomes

damaged or deformed in any way it must be replaced. If the light from the lamp appears dim this

would normally indicate that it is reaching the end of its life and it should be changed at once, old

lamps run to the extremity of their life can explode. If the projector does not function, check the fuses

on the power socket of the projector, they should only be replaced by fuses of the same specified

value 6.3A/250V (fast blow, 5mmx20mm). On the main PCB inside the projector there is also a fuse

rated 4A/250V (fast blow, 5mmx20mm). Should these be damaged call a qualified technician before

replacement. The projector has 2 thermal protection devices that will switch off the projector in case of

overheating, should either of these operate, check that the fans are not blocked, and if they are dirty

clean them before switching on the projector again. Check that the fans are operational, if not call a

qualified technician.

Any maintenance work should only be carried out by qualified technicians.

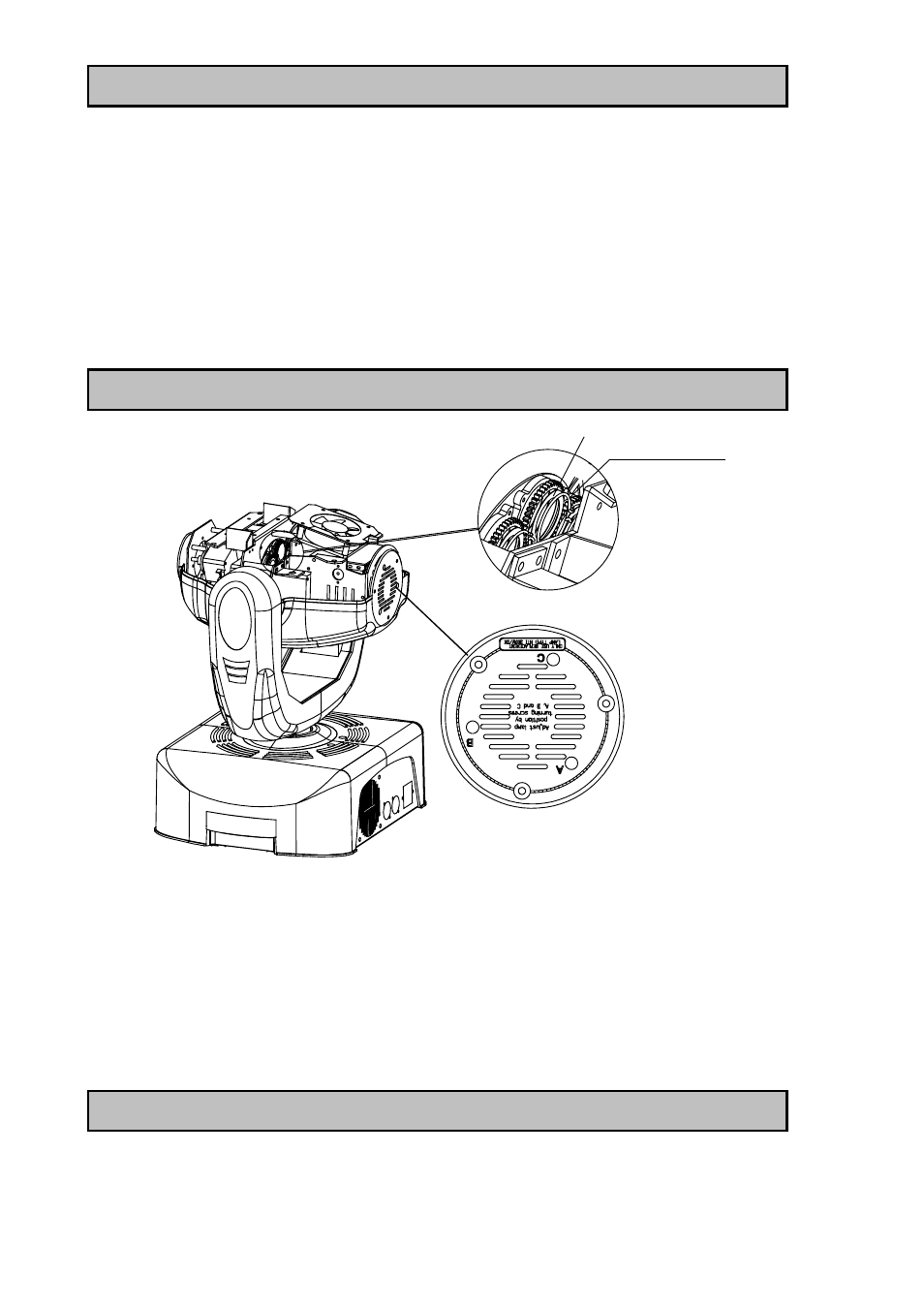

CHANGING THE GOBOS

LAMP ACCESS HATCH

(THE TEXT IS UPSIDE DOWN)

GOBO

RETAINING SPRING

Carefully lift off the plastic cover by undoing the 4 M4 screws. (NOTE: The projector has two covers

with the same shape. The cover removed must be right one, so you can change the gobos easily. How

to remove the correct cover, the easy way is to position the projector with the text of the lamp access

hatch upside down as shown above, and then remove the upper cover.)

Using a small screwdriver remove the gobo retaining spring.

Insert the new gobo into position, and then insert the retaining spring.

Mount the cover again and retighten the 4 M4 screws.

NOTE: It is recommended to add a little adhesive, such as high temperature silicon sealant, to hold

securely the retaining spring inside the gear.

LUBRIFICATION

pilot300_en.doc

8/14

To ensure the continued smooth rotation of the rotating gobos it is recommended that the wheel is

lubricated periodically, preferably every two months. Use only high working temperature low viscosity

oil, a syringe with a fine needle is the easiest way to introduce the oil to the bearings around each

gobo. Do not over lubricate as this will cause spillage when the wheel rotates.