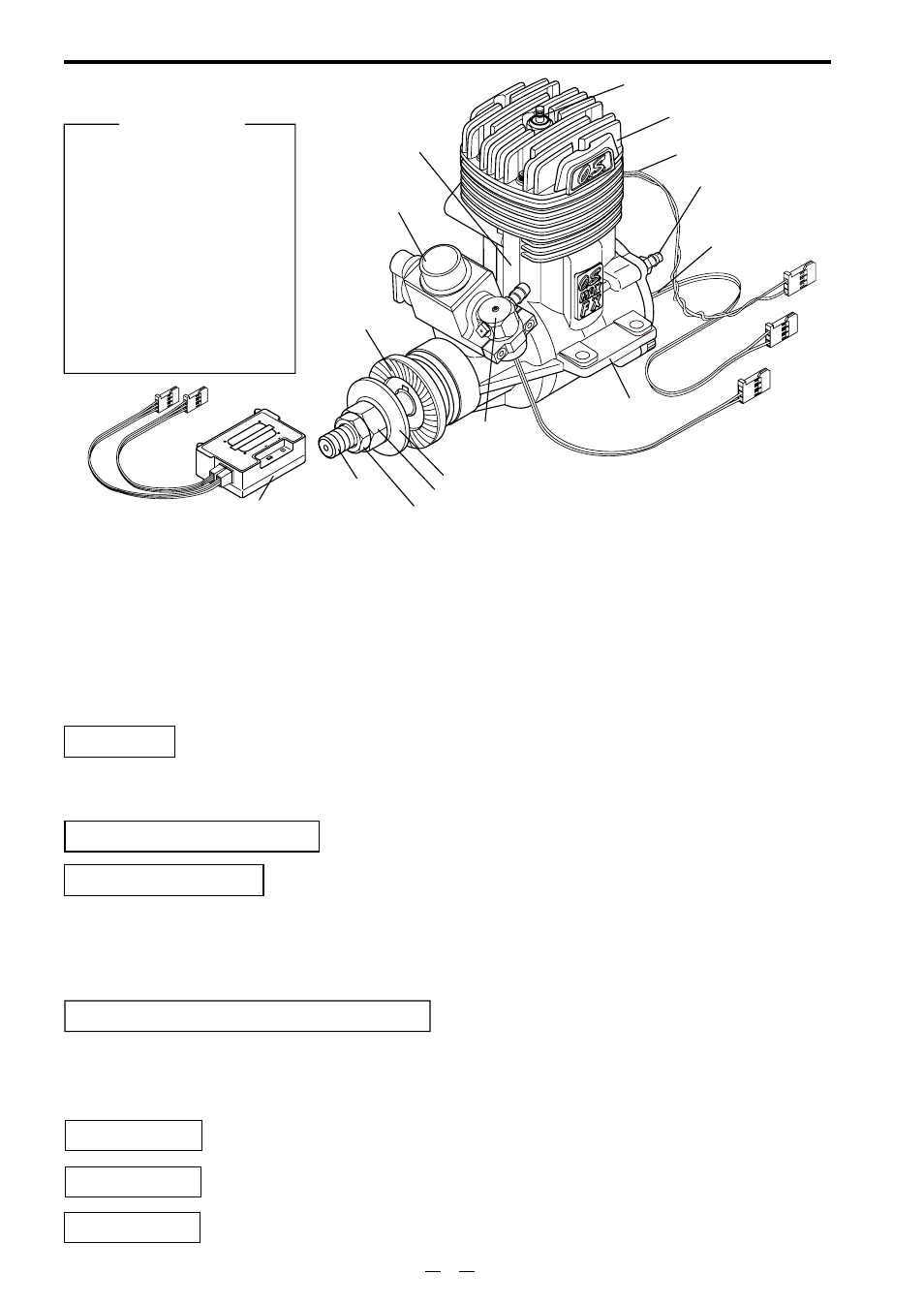

Basic engine parts, Injector, Temperature sensor – O.S. Engines 160FX-FI User Manual

Page 7: Rpm sensor, Electronic control unit

The injector consists of a solenoid valve with built-in regulator. It controls pressurized fuel at a constant

pressure and accurately injects fuel based on signals from the electronic control unit (EC-2).

Injector

Air Valve 70C

Injector

Drive Hub

Crankcase

BASIC ENGINE PARTS

Accessories

•Fuel Filter

•Check Valve

•Y harness

Electronic Control Unit

Glow plug No.8

Cylinder Head

Crankshaft

Temperature Sensor

Pressure Fitting

RPM Sensor

Injector

Never attempt to disassemble the injector.

It may not be able to be reassembled.

Temperature Sensor

This measures the temperature of the engine exhaust unit.

RPM Sensor

The RPM sensor is provided with a power generating sensor. When the crankshaft passes in front

of the sensor, the signal that is generated is transmitted to the electronic control unit (EC-2).

Engine speed is then calculated based on that signal which is then used to determine the timing at

which fuel is injected.

Electronic Control Unit

(abbreviated as simply EC-2)

The EC-2 transmits fuel injection signals to the injector to ensure the proper amount of fuel

injection based on basic fuel injection data that has been previously entered and constantly

changes with position of throttle stick.

Y harness

Fuel Filter

Check Valve

This cord is used to connect the receiver (throttle channel), throttle servo and EC-2.

This fine mesh filter prevents foreigh matter from the fuel tank from plugging

the small injector valve.

This one-way valve's function is to pressurize the fuel tank by crankcase

pressure and prevent fuel from returning to the engine crankcase.

•Driver to push Limit

Setting Switch

•Duble-sided sponge-

backed cushioning tape

INSTALLATION OF THE AIR VALVE

As delivered, the engine has its air valve lightly installed into the intake boss. Secure it as follows.

Loosen the retainer nut, rotate the air valve to its correct position and make sure that it is pressed

well down into the intake boss, compressing the rubber gasket, before retightening nut.

Rotate the retainer nut gently until it stops, then tighten a further 90-120˚.

Do not overtighten the screw as this will damage the thermo insulator.

1.

2.

Lock Nut

Propeller Nut

Propeller Washer

Beam Mount

•Glow plug No.8

•E-5010 Silencer

•EC-2 Assembly

6

✽