Carrier 50GS User Manual

Page 2

1. TURN OFF ALL ELECTRICAL POWER TO YOUR

UNIT AND INSTALL LOCK-OUT TAG BEFORE SER-

VICING OR PERFORMING MAINTENANCE. ELEC-

TRIC SHOCK COULD CAUSE SERIOUS INJURY OR

DEATH.

2. When removing access panels or performing maintenance

functions inside your unit, be aware of sharp sheet metal

parts and screws. Although special care is taken to keep

sharp edges to a minimum, be extremely careful when

handling parts or reaching into the unit.

Air Filters

The air filter(s) should be checked about every 4 weeks and

changed or cleaned whenever it becomes dirty. Dirty filters

produce excessive stress on the blower motor and can cause the

motor to overheat and shut down. Table 1 indicates the correct

filter size for your unit. Refer to Fig. 2 to access the filters.

To replace or inspect filters (or accessory filter rack when

supplied):

1. Remove the filter access panel using a 5/16-in. (7.9 mm) nut

driver or wrench.

2. Remove the filter(s) by pulling it out of the unit. If the filter(s)

is dirty, clean or replace with a new one.

When installing the new filter(s), note the direction of the airflow

arrows on the filter frame.

If you have difficulty locating your air filter(s) or have questions

concerning proper filter maintenance, contact your dealer for

instructions. When replacing filters, always use the same size and

Never operate your unit without the filter(s) in place. Failure

to heed this warning may result in damage to the blower

motor and/or compressor. An accumulation of dust and lint on

internal parts of your unit can cause loss of efficiency and, in

some cases, a fire.

Fans and Fan Motor

Periodically, check the condition of fan wheels and housings and

fan-motor shaft bearings. Contact your dealer for the required

annual maintenance.

Indoor and Outdoor Coils

Cleaning of the coils should only be done by qualified service

personnel. Contact your dealer for the required annual mainte-

nance.

Condensate Drain

The drain and condensate line should be checked and cleaned at

the same time the cooling coils are checked by your dealer.

Compressor

All compressors are factory-shipped with a normal charge of the

correct type refrigeration grade oil. A compressor should rarely

require additional oil.

Condenser Fan

Do not poke sticks, screwdrivers, or any other objects into

revolving fan blades. Injury or equipment damage may result.

The fan must be kept free of all obstructions to ensure proper

cooling. Contact your dealer for any required service.

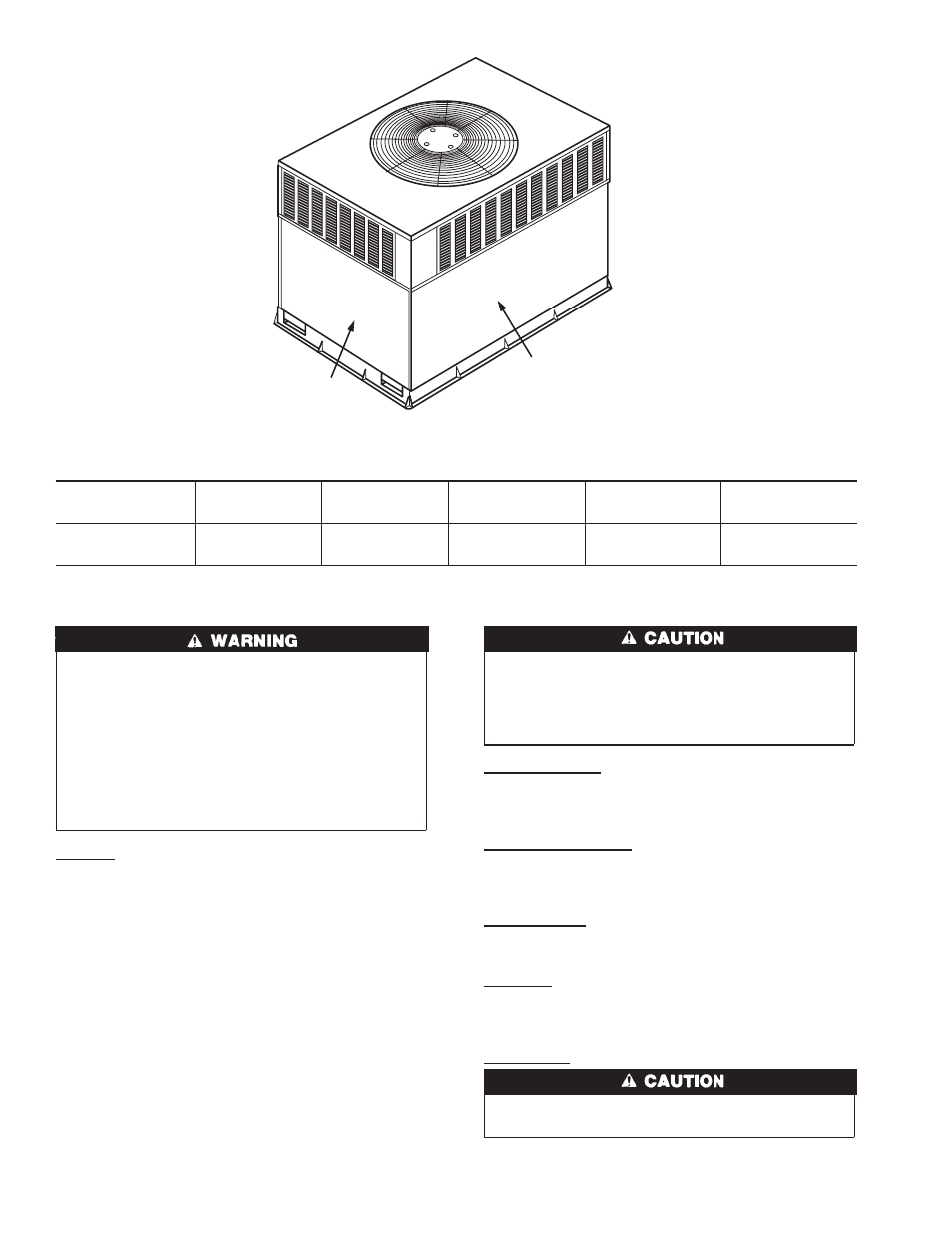

Fig. 2—Filter Access Panel-Vertical Supply Shown

(Unit Shown with Optional Louvered Grille)

Table 1—Indoor-Air Filter Data

UNIT SIZE

50GS

(50 HZ)

024

030

036

048

060

RETURN-AIR

FILTER (mm)

Throwaway

20” x 20”

(508 x 508)

20” x 20”

(508 x 508)

20” x 24”

(508 x 609.6)

24” x 30”

(609.6 x 762)

24” x 30”

(609.6 x 762)

C00160

ACCESS PANEL

FILTER ACCESS

PANEL*

*For accessory filter rack.

2