Milwaukee Tool 6066-6 User Manual

Page 7

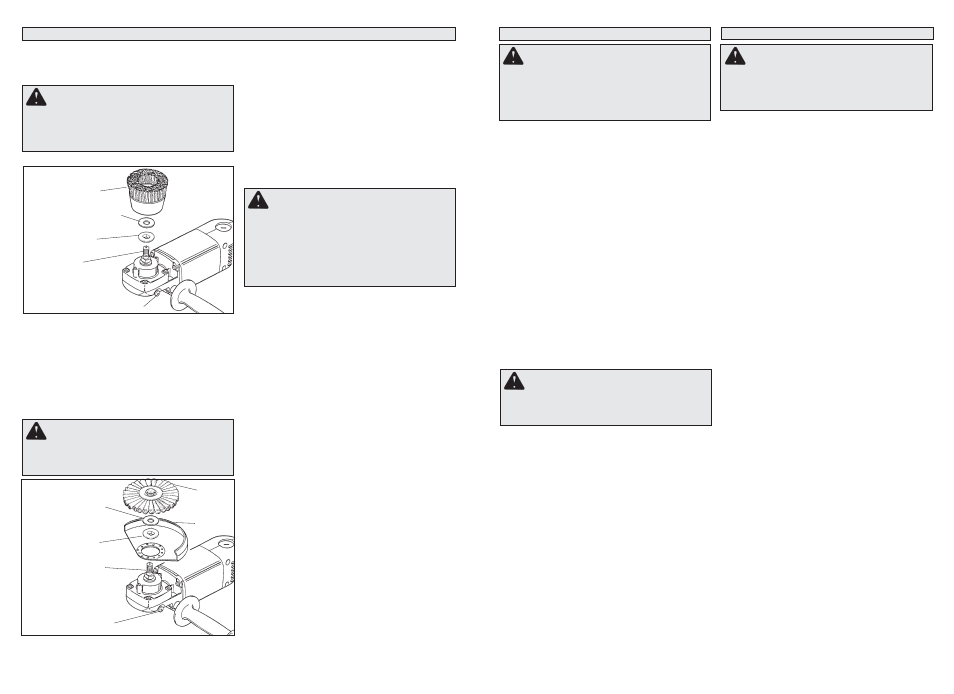

12

13

1. Unplug tool and place it upside down on a level

surface. Remove any accessories from spindle.

NOTE:

Never use a guard with a wire cup brush.

2. Thread fl ange and nylon washer onto spindle.

Attach wire cup brush onto spindle.

3. Press in the spindle lock button while tightening

brush with a wrench (not provided with tool).

4. To remove wire cup brush, unplug tool and re-

verse procedure.

Installing Wire Cup Brushes

Spindle lock button

Fig. 8

Wire cup brush

Nylon washer

Spindle

Flange

1. Do not wear loose clothing when using wire

brushes. The wires may catch on loose clothing

and pull the clothing into the moving parts.

2. Firmly grasp rear handle and side handle before

starting and while using tool. Always test the wire

brush for balance and loose or damaged wires

by running tool at no load speed for at least one

minute before applying it to your work.

3. When applying brush to work, avoid using too

much pressure. This causes over-bending of

wires and heat build-up resulting in premature wire

breakage, rapid dulling and reduced brush life.

Instead of using more pressure, try a wire wheel

brush with more aggressive cutting action

(increased wire size, decreased wire length or

different brush type, i.e. knot type instead of

crimped wire type).

1. Unplug tool and place it upside down on a level

surface. Remove any accessories from spindle.

2. Thread fl ange and nylon washer onto spindle.

Attach guard and wire wheel brush onto spindle

(see Fig. 4 for attaching guard).

Position the guard in the location which offers

best control and guard protection. For operating

zones that provide maximum protection for the

operator, see "Grinding".

3. Press in the spindle lock button while tightening

brush with a wrench (not provided with tool).

4. To remove wire wheel brush and guard, unplug

tool and reverse procedure.

Installing Wire Wheel Brushes

Using Wire Brushes

WARNING

Because the wires on wire

wheel brushes are directed towards the opera-

tor, a Type 27 guard must be used to protect

the operator when fatigued wires break.

Wire

wheel

brush

Fig. 9

Guard

Nylon

washer

Spindle

Spindle lock button

Flange

WARNING

Never exceed Maximum

Safe Operating Speed of the brush. Do not use

a damaged brush or one which is functioning

improperly (throwing wires, out-of-balance,

etc.). These conditions increase the pos-

sibility of further brush failure and possible

injury. Discard and replace damaged brushes

immediately.

USING WIRE BRUSHES

Selecting Wire Brushes

Wire brushes are useful for removing rust, scale,

burrs, weld slag, etc. A wide variety of wire brushes

are available for many applications.

WARNING

Everyone in the area must

wear protective clothing and safety goggles

or face shields. Fatigued wires and residue

will fl y off the brush with considerable force,

causing the potential for serious injuries.

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

WARNING

To reduce the risk of injury,

always unplug the tool before attaching or

removing accessories. Use only specifi cally

recommended accessories. Others may be

hazardous.

WARNING

To reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.

MAINTENANCE

WARNING

To reduce the risk of injury,

always unplug your tool before performing

any maintenance. Never disassemble the tool

or try to do any rewiring on the tool’s electrical

system. Contact a MILWAUKEE service facility

for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, bro-

ken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. Tag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

Under normal conditions, relubrication is not neces-

sary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical

operation

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include: gasoline, turpentine, lacquer thin-

ner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

ACCESSORIES