Trouble shooting (continued) – Milwaukee Tool 9566 V.2 User Manual

Page 14

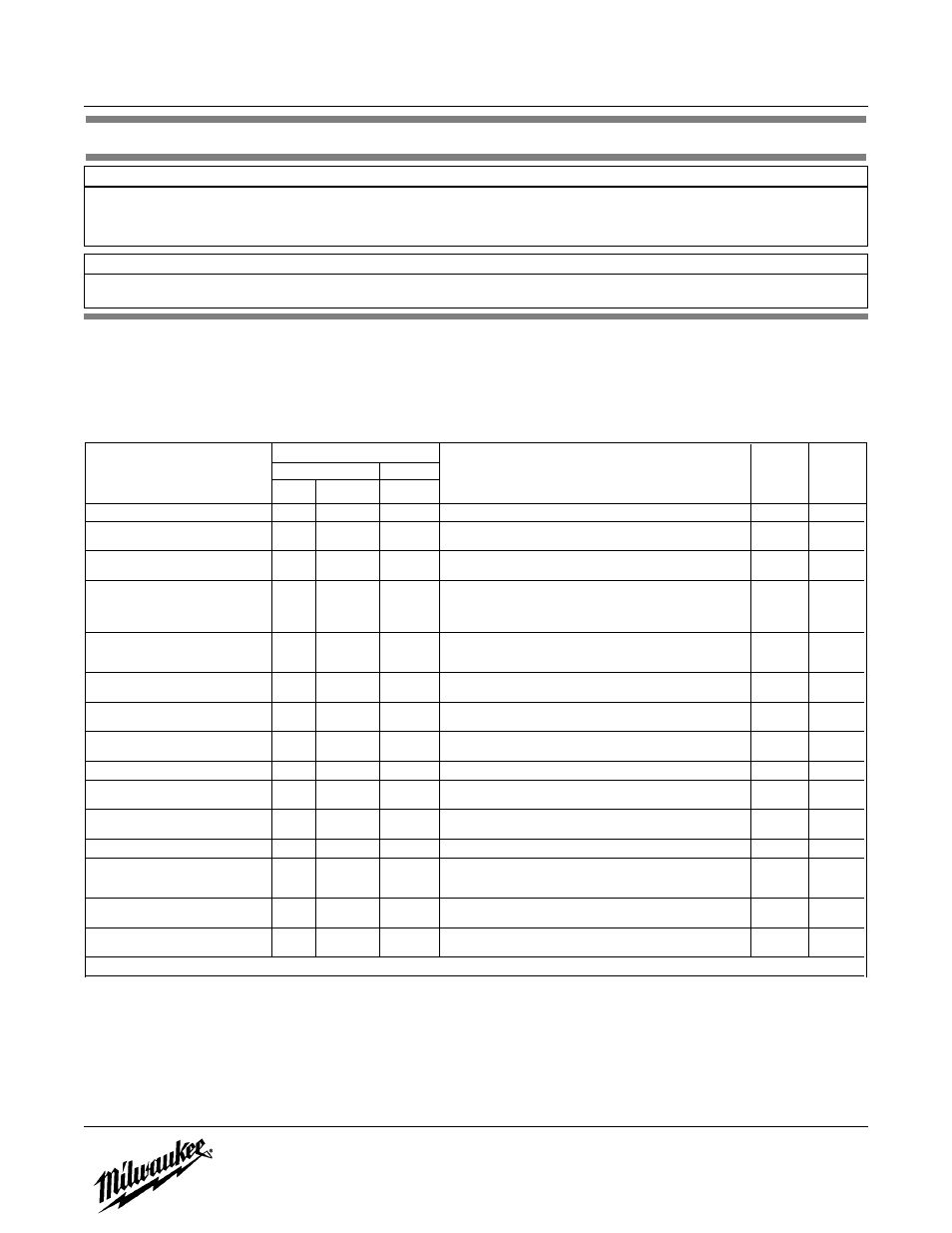

INSPECTION AND MAINTENANCE CHECK LIST

ELECTRIC POWERED OVERHEAD CHAIN HOIST

Type of Hoist ______________________________________________________

Capacity (Tons) ____________________________________________

Location _________________________________________________________

Original Installation Date _____________________________________

Manufacturer______________________________________________________

Manufacturer’s Serial No. ____________________________________

Item

Frequency of Inspection

Possible Deficiencies

OK

Action

Frequent

Periodic

Required

Daily

Monthly

1-12 Mo.

Operating Controls

*

*

*

Any deficiency causing improper operation

Limit Switches

*

*

*

1. Any deficiency causing improper operation

2. Pitting or deterioration

Brake Mechanism

*

*

*

1. Slippage or excessive drift

2. Glazing, contamination or excessive wear

Hooks

*

*

*

Excessive throat opening 15% bent or twisted more than 10

degrees, damaged hook latch, wear, chemical damage,

worn hook bearing. To find cracks, (use dye penetrant,

magnetic or other suitable detection methods)

Suspension Lug (if used)

*

*

*

Cracks, excessive wear or other damage which may impair

the strength of the lug. To find cracks, (use dye penetrant,

magnetic particle or other suitable detection methods)

Chain

*

*

*

Inadequate lubrication, excessive wear or stretch, cracked,

damaged or twisted links, corrosion or foreign substance

Hook and Suspension

*

Cracks, bending, stripped threads

Lug Connections

Pins, Bearings, Bushings

*

Excessive wear, corrosion, cracks, distortion

Shafts, Couplings

Nuts, Bolts, Rivets

*

Looseness, stripped and damaged threads, corrosion

Sheaves

*

Distortion, cracks, and excessive wear.

Build-up of foreign substances

Housings, Load Block

*

Cracks, distortion. Excessive wear, internal build-up of

foreign substances

Wiring and Terminals

*

Fraying, defective insulation

Hoist Reversing

Contactor, other Electrical

*

Loose connections, burned or pitted contacts

Apparatus

Supporting Structure

Damage or wear which restricts ability to support

and Trolley (if used)

*

imposed loads

Nameplates, Decals,

*

Missing, damaged or illegible

Warning Labels

NOTE: Refer to Maintenance and Inspection Sections of the Hoist-Maintenance Manual for further details.

FREQUENCY OF INSPECTION

Frequent — Indicates items requiring inspection daily to monthly. Daily inspections may be performed by the operator if properly designated.

Periodic — Indicates items requiring inspection monthly to yearly. Inspections to be performed by or under the direction of a properly designated period. The exact

period of inspection will depend on frequency and type of usage. Determination of this period will be based on the user’s experience. It is recommended

that the user begin with a monthly inspection and extend the periods to quarterly, semi-annually or annually based on user’s monthly experience.

Figure 10A — Recommended Inspection and Maintenance Check List

NOTE:

This inspection and maintenance check list is in accordance with our interpretation of the requirements of the Safety

Standard for Overhead Hoists ASME B30.16. It is, however, the ultimate responsibility of the employer/user to interpret and

adhere to the applicable requirements of this safety standard.

14

Milwaukee Electric Tool Corporation

13135 West Lisbon Road

Brookfield, Wisconsin 53005

TEL: (800) 729-3878

1. Brake needs adjustment

1. See BRAKE ADJUSTMENT, page 9.

2. Broken shading coil on brake frame

2. Replace shading coil or complete brake frame assembly.

Motor brake “buzz” (anytime hoist is running)

TROUBLE SHOOTING (Continued)

1. Brake needs adjustment

1. See BRAKE ADJUSTMENT, page 9.

2. Low voltage

2. Check voltage at the hoist reversing contactor while the hoist is lifting a load.Voltage should be no less than 90% of

the voltage specified. 115 volt hoists are particularly subject to voltage drop problems due to their high current draw.

Conversion to 230 volt operation is suggested in extreme cases.

Motor brake noise or chatter (while starting hoist)