Milwaukee Tool 9566 V.2 User Manual

Page 11

11

7. Reassemble in reverse order of disassembly making sure

gasket is in place and in good condition. Coat gasket with

Permatex

®

or other gasket cement. Extreme care should be

taken to avoid damage to oil seals.

8. Check all wire terminals to be sure they are properly seated

and in accordance with wiring diagram. Before placing

hoist back into service, check brake adjustment and limit

switch stops.

Suspension

Use Replacement Parts List for Basic Hoist and Chaining Parts

to help in repairs in this section (See Figures 12 and 20). The

hoist sections must be separated at the top hook line in order

to inspect the load sheave and chain guides. See CHAIN

REPLACEMENT WITH NO CHAIN IN HOIST, page 8.

While this section is apart, check the following:

• Load sheave

• Chain guides and plates

• Chain

• Chain support (on 2 ton models)

• Bearings

Replace parts as necessary including screws, lockwashers,

etc.

When reassembled, recheck limit switch operation. See LIMIT

SWITCH ADJUSTMENT, page 8.

Periodic inspections of the top suspensions can be made

without disassembly. For more extensive inspections the lug

maybe removed as follows:

1. Disconnect the hoist and remove it to workbench.

2. Remove the lug retaining screw.

3. Remove the lug retainer.

4. Remove the lug.

Care must be taken during reassembly to have the hook in

proper orientation. Refer to figures 8A & 8B for proper

orientation. The transmission must be disassembled in order to

inspect load sheave and chain guide (see CHAIN

REPLACEMENT WITH NO CHAIN IN HOIST, page 8). When

reassembled, recheck the limit switch settings (See LIMIT

SWITCH ADJUSTMENT, page 8).

Milwaukee Electric Tool Corporation

13135 West Lisbon Road

Brookfield, Wisconsin 53005

TEL: (800) 729-3878

M a x i m u m L e n g t h o f P o w e r C o r d i n F e e t

HP

Voltage

14 AWG

12 AWG

10 AWG

8 AWG

(1-Phase)

Table 3 - Recommended Conductor Sizes for 1-Phase Hoists

POWER CORD PRECAUTIONS WITH 1-PHASE HOISTS

Electric hoists require a sufficient power supply. It is especially important with single-phase voltage to ensure that the conductors

running to the hoist from the power source are adequate in size to handle the power requirements of the hoist. Inadequate

power cables and branch circuits will cause low voltage, high amperage, damage to the hoist, and potential fire hazards.

Such problems can be minimized by using 230V power on 115/230V hoists. The following are recommendations for the conductor

gage size depending on the length, horsepower, and voltage.

1

115V

0

30

50

75

230V

120

190

310

490

1/2

115V

40

60

100

150

230V

200

330

520

810

Failure to follow proper lockout/tagout procedures may

present the danger of electrical shock.

TO AVOID INJURY:

Disconnect power and lockout/tagout disconnecting

means before removing cover or servicing this

equipment.

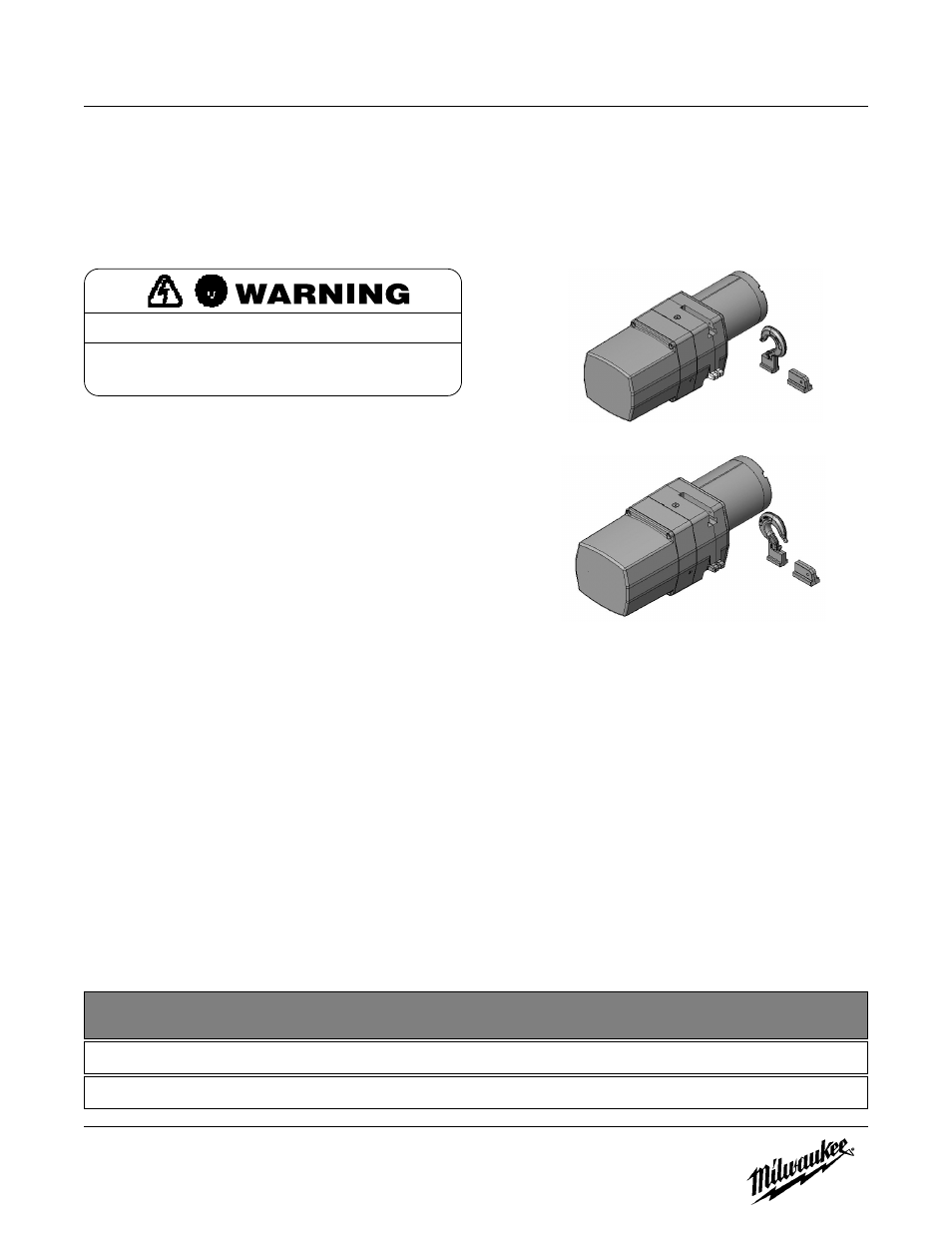

Figure 8A - Single Chain Lug Orientation

Figure 8B - Double Chain Lug Orientation