1 quick-check, Table 1 – Leslie Controls D Series User Manual

Page 3

CFTIIP-015

Rev.0

__________________________________________________________________________________

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 3 of 15

4 Installations

1. Before installing the valve, clean the line of dirt,

welding chips, scale or other foreign material.

2. Whenever possible, the valve should be installed

in an upright position. Vertical installation permits

easier valve maintenance.

3. Be sure to provide proper overhead clearance for

the actuator to allow for disassembly of the plug

from the valve body

4. Double-check flow direction to be sure the

valve is installed correctly. Flow direction is

indicated by the arrow attached to the body.

5. If welding the valve into the line, use extreme

care to avoid excess heat buildup in the valve.

6. Connect the air supply and instrument signal

lines. Throttling control valves are equipped with a

valve positioner. Refer to the appropriate positioner

bulletin for connections, maximum air supplies, and

maintenance instructions.

4.1 Quick-check

Prior to start-up, check the control valve by

following these steps:

1. Stroke the valve and observe the plug position

indicator on the stem clamp compared to the stroke

indicator plate. The plug should change position in

a smooth, linear fashion.

NOTE: Due to excessive friction, graphite packing

can cause the plug stem to move in a jerky fashion.

2. Check for full stroke by making appropriate

instrument signal change.

3. Check all air connections for leaks.

4. Check packing box bolting for the correct

adjustment.

CAUTION: Do not over tighten

packing. This can cause excessive packing

wear and high stem friction that may impede

plug movement.

5. Make sure the valve fails in the correct

direction in case of air failure. This is done

by turning off the air supply and observing

the failure direction.

6. After a temperature excursion has

occurred, bonnet flange bolting should be re-

torqued to ensure bonnet gaskets do not leak.

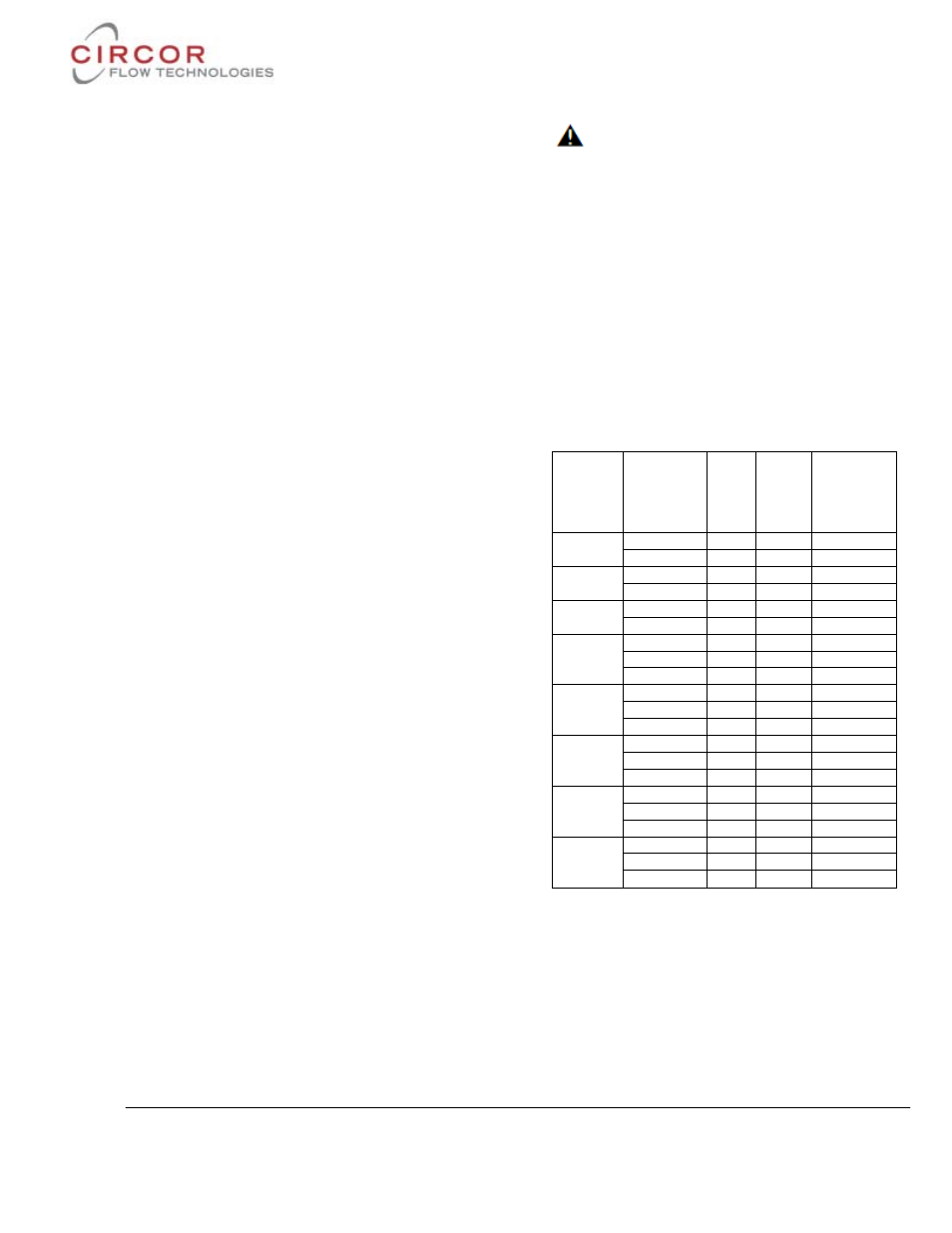

(Refer table 1)

Table 1

SIZE

OF THE

VALVE

CLASS

SIZE

OF

THE

NUT

(in)

NO.

OF

NUTS

TORQUE

Nm

2"

150 ~ 600

0.75

6

152

900 ~ 1500

0.875

8

220

3"

150 ~ 600

0.875

8

233

900 ~ 1500

1.25

8

583

4"

150 ~ 600

0.875

8

307

900 ~ 1500

1.5

8

922

6"

150 ~ 600

1

12

391

900

1.25

12

856

1500

1.75

8

1798

8"

150 ~ 600

1

12

573

900

1.75

8

2631

1500

1.625

12

1629

10"

150

1

8

879

300

1

12

586

600

1.25

16

550

12"

150

1

12

873

300

1.25

12

1091

600

1.5

16

982

16"

150

1.25

12

1605

300

1.5

12

1926

600

1.75

16

1685