Leslie Controls D Series User Manual

Page 11

CFTIIP-015

Rev.0

__________________________________________________________________________________

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 11 of 15

Plug stem pinning during field assembly

may be divided into two parts:

— Replacing old plug and old stem,

— Replacing only old stem.

Replacing Plug and Stem

The plug (15) and stem (20) assembly

consists of a shaft threaded into the plug and

pinned in place. To replace the stem (20) it is

necessary to drill or drive out the pin (19)

and unscrew the stem (20) from the plug

(15).

If it is necessary to replace the plug, it is

necessary to replace the plug stem at the

same time. Indeed, the original pin hole in an

old stem prevents satisfactory results and

might seriously impair strength of the

assembly.

A. Reference Marking on the Plug Stem

Measure the depth of the pilot recess in the

plug (X in Figure 5) and make a reference

mark to the plug stem at the same distance,

from the thread.

B. Screwing Stem into Plug

1. Hold the plug in a vise.

2. Apply a small amount of grease such as

Gripcott® (or an equivalent compatible with

the fluid process) on the threaded part of the

plug stem.

3. Lock one nut against another one to the

end of the new plug stem and, using a

wrench on the upper nut, screw the stem

solidly into the plug. When properly

assembled, the reference mark should be

flush with the end of the plug shank.

C. Drilling the New Parts

1. Measure the “D” dimension,

(See Table 3).

2. Place the plug shank on a V-block and, by

means of a centre punch, make a centre mark

on the plug shank area.

3. Using a suitable size drill bit, drill the

plug-stem assembly. After drilling, remove

any burrs from the plug shank by making a

slight chamfer.

D. Pinning the Plug-Stem Assembly

1. Select the correct size pin according to

plug shank diameter and stem diameter, (see

Table 3). Apply a small amount of grease

on

it, and hand place the pin to the hole inlet.

2. By means of an hammer, introduce the pin

into the hole. Use a flat-ended punch to

ensure the pin is recessed by the same

amount at both sides, (see Figure 5).

3. After the plug has been pinned, it should

be placed in a lathe to insure it is running

“true.” The stem should be placed in a collet

with the plug shank against it and the plug

should be struck on the non guiding surface

of the plug using a mallet / nylon hammer

without causing mechanical damage to the

surface. Alignment of plug stem can be

performed using appropriate means.

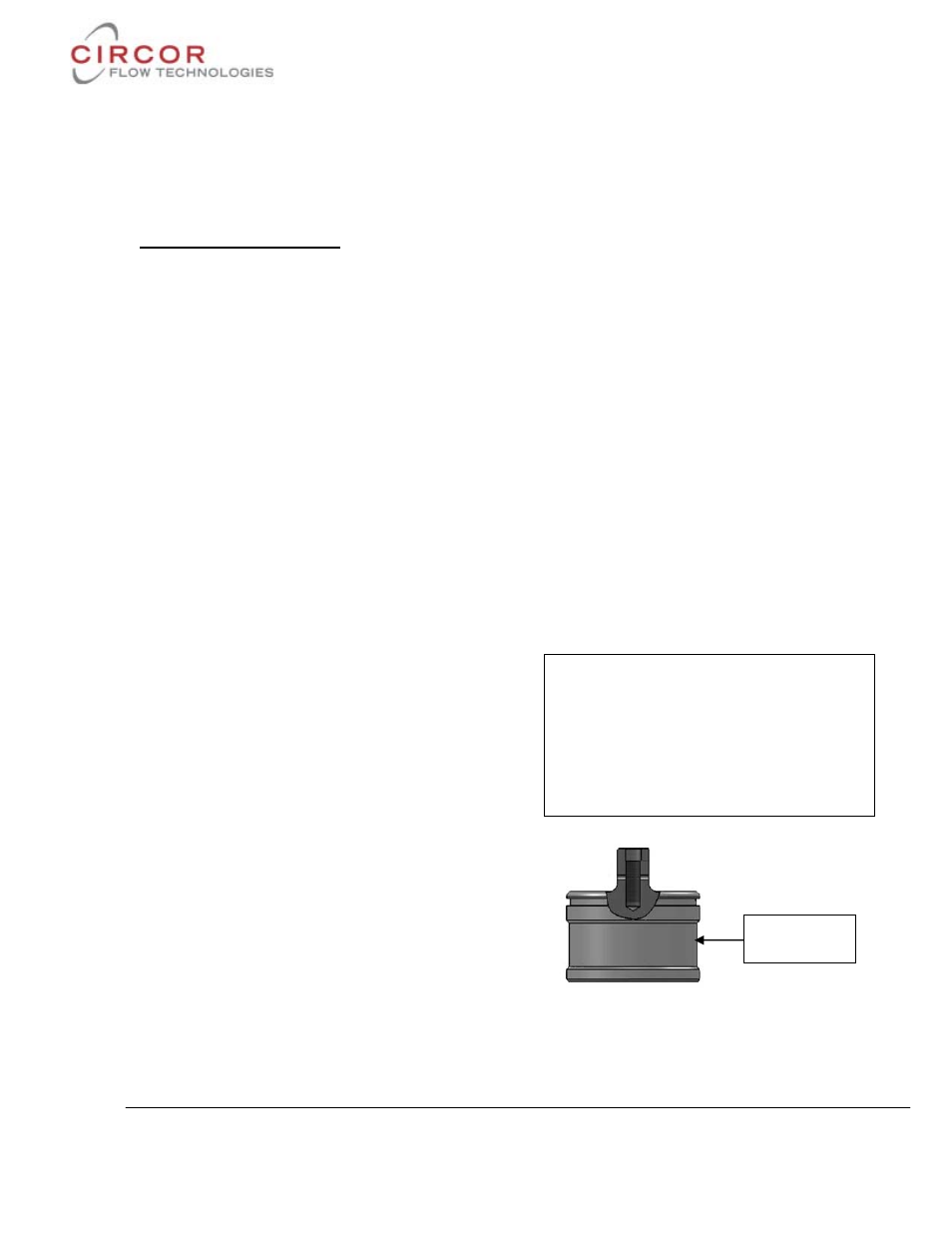

Note: While pinning is being performed, care

must be taken not to damage the seating

surface or plug guide. In holding plug in

order to tightening the plug stem, always

tighten the jaws of the vise on a non-guiding

surface of the parts. Always use a soft metal

vise jaw with a special machining to hold the

shank of the plug (see Figure 5.1).

Figure 5.1 – Plug

Non-guiding

Surface