LAARS NeoTherm NTV600 - Install and Operating Manual User Manual

Page 31

NeoTherm Boilers and Water Heaters

Page 29

6B.2 Piping Requirements

Water piping should be supported by suitable

hangers and floor stands. Do not support piping with the

appliance. Due to expansion and contraction of copper

pipe, consideration should be given to the type of

hangers and supports used. Rigid hangers may transmit

noise through the system resulting from piping sliding

in the hangers. It is recommended that padding be used

when rigid hangers are installed. Maintain 1" (2.5cm)

clearance to combustibles for hot water pipes.

Pipe the discharge of the relief valve (full size) to

the drain or in a manner to prevent injury in the event of

pressure relief. Install a diaphragm-type expansion tank,

flow check, and shutoff valves where needed or as

required by code.

NeoTherm 80-500 can be ordered with pumps.

Whether the factory pumps or other pumps are installed

the piping should be installed such that the pump

supplies flow to the heater it is attached to only. The

factory pumps are sized for 30 feet and 6 elbows of total

pipe length, so the heater should be placed within 15

feet of the tank. If longer runs are required, properly-

sized field-supplied pumps should be used.

SECTION 6B.

Water Connections - NTV Water Heater

Section 6 is divided into two parts. The first is

for NTH models and is Section 6A. The second

is for NTV models and is Section 6B. Refer to

the proper section for instructions in installing

and piping your product. Refer to

Table 9

for

pipe sizes required.

6B.1 NTV Water Quality

NTV water heaters must be installed in water

conditions of 10gpg hardness or less with a pH range of

8.2 to 9.5. Operating the NTV in water with higher

hardness levels will cause heat exchanger fouling,

erosion, or corrosion leading to premature component

failure, reduced efficiency, heat exchanger failure or

system failure. Failure of this type will not be

warranted. If the water in use exceeds the conditions

recommended water softeners or other devices should

be installed to improve water quality.

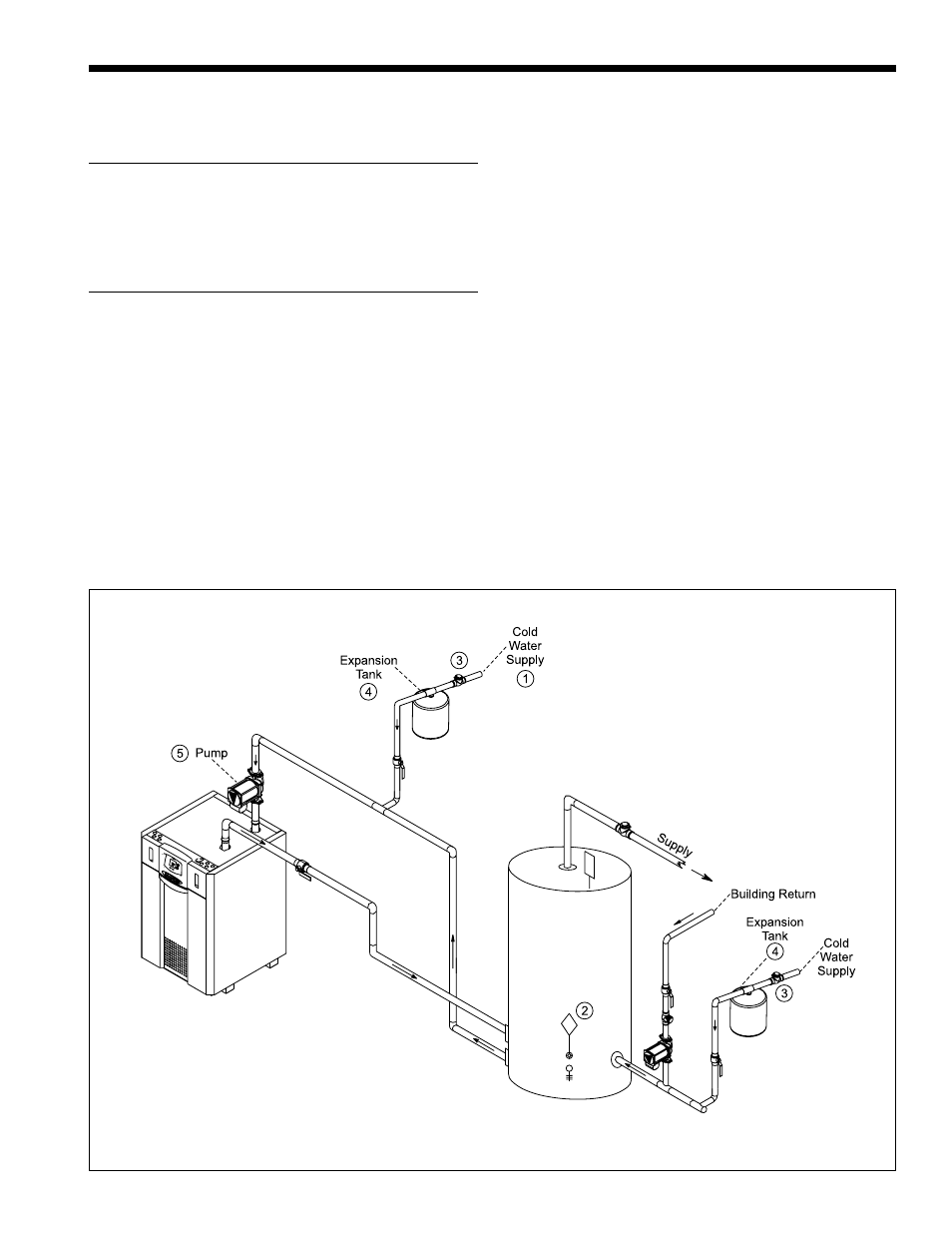

Figure 23. DHW Piping, One Heater, One Vertical Tank.

NOTES:

1. Optional CWMU & Recirc. line location.

2. Locate NTV DHW sensor or remote aquastat well

in lower 1/3 of tank.

3. Back flow preventer may be required - check local codes.

4. Thermal expansion tank may be required - check local codes.

5. Factory mounted pumps are sized for a max pipe length of

30' total, 6-90° elbows, full pipe size.

6. Caution: Pump sizing must be based opon water hardness at job site.

WARNING: THIS DRAWING SHOWS

SUGGESTED PIPING CONFIGURATION AND

VALVING. CHECK WITH LOCAL CODES AND

ORDINANCES FOR ADDITIONAL REQUIREMENTS.