Laars heating systems – LAARS Mini-Therm JVi - Install and Operating Manual User Manual

Page 9

LAARS Heating Systems

Page 8

(b)

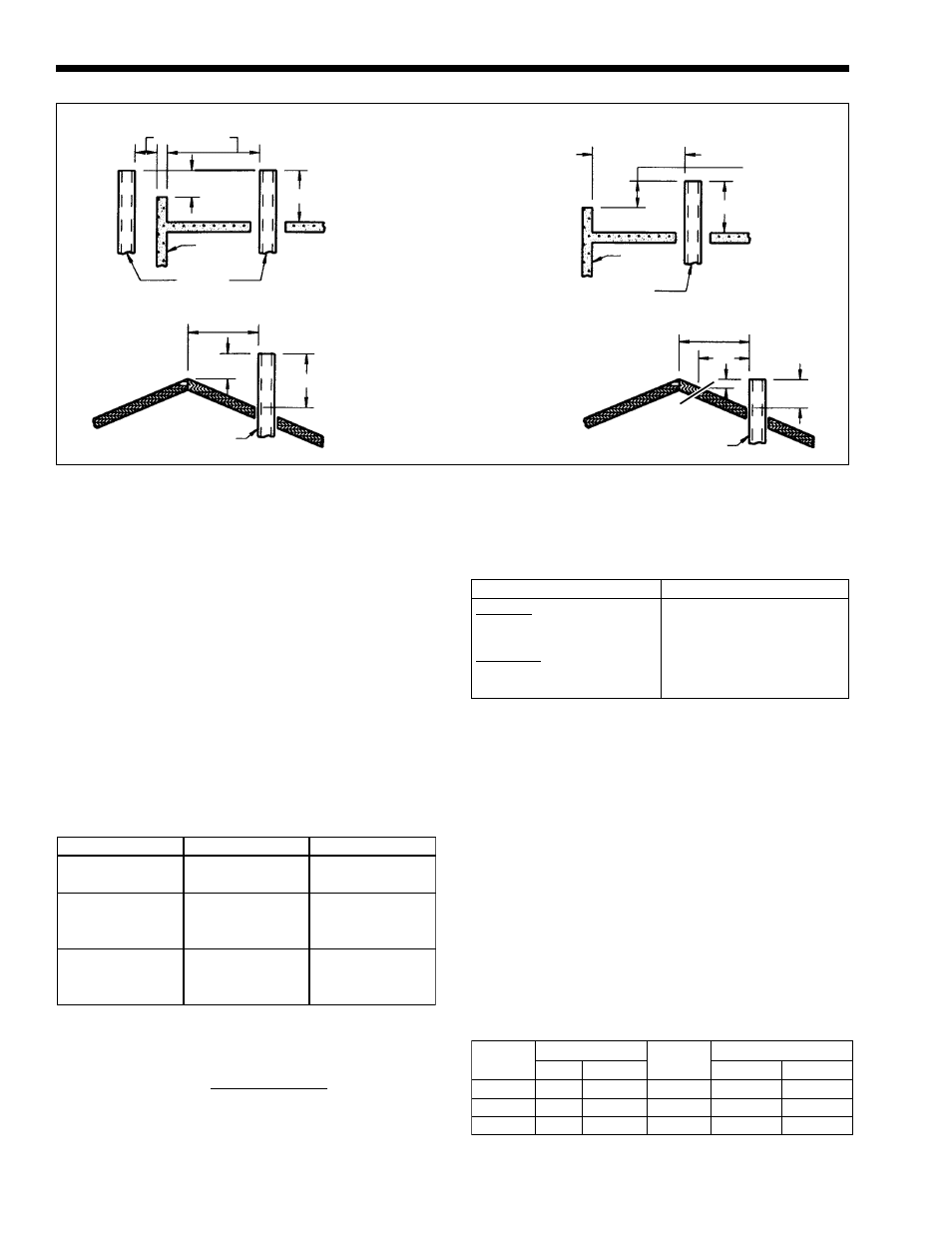

Vent Termination

A listed vent terminal designed for the type of

pipe being used must complete the vertical run where

it exits the chimney. The vent pipe must extend at

least 3' (.9m) above the highest point where it passed

through the roof. In addition, the vent cap must be at

least 2' (.6m) higher than any portion of a building

within a horizontal distance of 10' (3m). Clearance to

any combustible materials must be maintained as

listed (see Figure 6).

1H-2. Horizontal Venting - Category III

When venting is horizontal, or cannot meet the

requirements of Category I, it can develop positive

pressure and must be installed in accordance with this

section and the specific vent manufacturer’s

instructions.

For best results, horizontal vent systems should

be as short and straight as possible. Material of vent

connectors shall be as follows:

WALL OR

PARAPET

CHIMNEY

CHIMNEY

RIDGE

WALL OR

PARAPET

CHIMNEY

CHIMNEY

RIDGE

10 (3.0) OR

LESS

Figure 6. Vertical Vent Termination.

2 (0.6) MIN.

3 (0.9)

MIN.

10 (3.0)

OR LESS

2 (0.6)

MIN.

3 (0.9)

MIN.

3 (0.9)

MIN.

3 (0.9)

MIN.

2 (0.6)

MIN.

10 (3.0)

MORE THAN 10

(3.0)

MORE THAN 10

(3.0)

NOTE: NO HEIGHT

ABOVE PARAPET

REQUIRED WHEN

FROM WALLS OR

PARAPET IS MORE

THAN 10 FT. (3.0m)

TERMINATION

10 FT. (3.0m)

OR LESS FROM RIDGE,

WALL OR PARAPET

(a)

Vent Connections

The vent system must be gas tight. All seams and

joints must be sealed with silicone sealant or adhesive

tape having a minimum temperature rating of 400°F

(204ºC) (see Table 9 for a list of approved sealing

materials). Use at least three corrosion resistant

screws at each slip joint, when required.

Description

Manufacturer

Product

High Temperature

RTV

Dow Corning

Trade mate

2" (51mm) wide

Aluminum foil tape

- adhesively backed

Venture

Product #3243

2" (51mm) wide

Aluminum foil tape

- adhesively backed

3M

Product #433

Table 9. Vent Sealing Materials.

Materials

Vent Length

In U.S.A.: UL type 304, 316

Up to a maximum of 55' (17m)

or 294-C stainless steel,

of equivalent pipe run

26 gauge minimum.

(including required elbows).

In Canada: Use “BH” vent

type complying with ULC

S-636 Standard.

For each elbow eliminated, add 5' (1.5m) of allowable vent.

Table 10. Horizontal Venting Configuration.

The boiler vent collar must be fastened to the

vent pipe of the same diameter, with rustproof metal

screws no longer than 1/2" (13mm) and sealed with

high temperature (500ºF / 260ºC) silicone sealant. For

larger diameter vent pipes, use a sealed reducer

fastened directly to the boiler collar and seal all joints

as indicated in Figure 7. Allow the sealant to cure for

24 hours before operating the boiler.

The entire vent system must not exceed the size

specified in Table 10.

The following criteria must be observed:

1.

Attach a vertical pipe at least 12" (305mm) high

to the boiler outlet before the horizontal run if

run exceeds 5 feet (see Figure 7).

2.

Support the vent run at 3' (.9m) intervals with

overhead hangers.

Dimensions in feet (m).

e

z

i

S

r

e

t

e

m

a

i

D

f

o

.

o

N

s

w

o

b

l

E

h

t

g

n

e

L

n

u

R

l

a

t

n

o

z

i

r

o

H

.

n

i

m

m

.

t

f

m

0

6

1

-

0

5

4

2

0

1

4

5

3

7

.

0

1

5

2

2

4

2

0

1

2

0

1

0

.

3

5

2

2

6

2

5

1

4

5

3

7

.

0

1