1 gas supply and piping – LAARS Mighty Therm2 MT2V (Sizes 500–2000 MBTU/h) - Install and Operating Manual User Manual

Page 13

Mighty Therm

2

Page 13

galvanized pipe and elbows to allow the open end to face

down aside the boiler. This is available as a Commercial

Kit from the manufacturer.

Part numbers for the low profile terminals to cover the

vent and combustion air openings are shown in Table 6.

SECTION 3.

Gas Supply and Piping

3.1 Gas Supply and Piping

Gas piping should be supported by suitable hangers

or floor stands, not by the appliance.

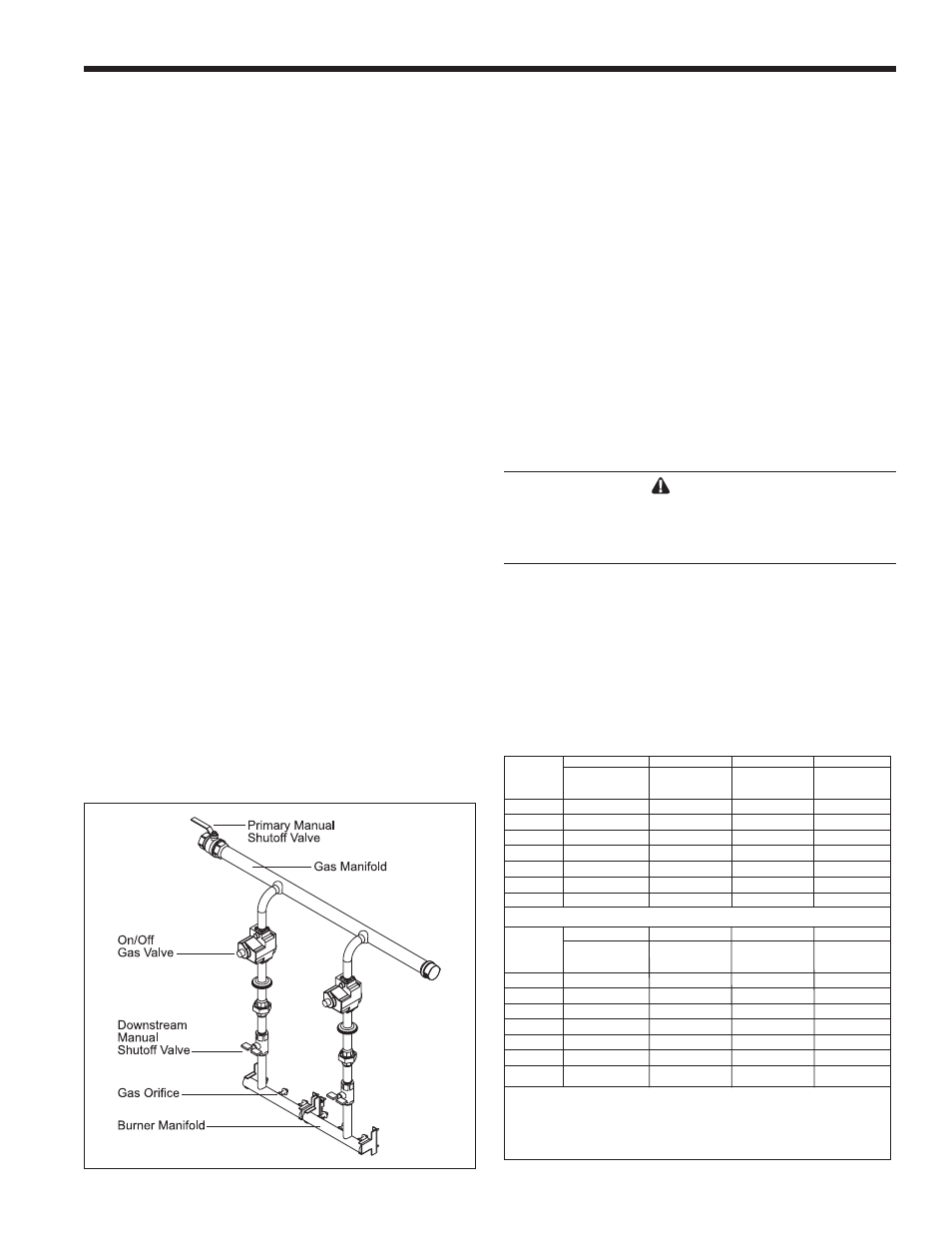

Mighty Therm2’s gas train allows the user to pipe

the gas from either the right side or the left side of the

unit. As shipped, the right side of the gas train is capped

off, and there is a manual valve on the left side. If

desired, the manual valve on the left side of the gas train

may be moved to the right side, and the cap on the right

side may be moved to the left.

Review the following instructions before

proceeding with the installation.

1. Verify that the appliance is fitted for the proper type

of gas by checking the rating plate. Mighty Therm2

appliances are equipped to operate at elevations up

to 10,000 feet (3050m). Mighty Therm2 appliances

may be adjusted to operate properly at altitudes

above 2500 feet (see

Section 6.6.2

) and the input

will be reduced if the heating value of the gas

supply is below sea level values.

2. The maximum inlet gas pressure must not exceed

13" W.C (3.2kPa). The minimum inlet gas pressure

is 5" W.C. (1.2kPa).

3. Refer to

Table 7

, size supply.

4. Run gas supply line in accordance with all

applicable codes.

5. Locate and install manual shutoff valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of the

gas controls.

7. All threaded joints should be coated with piping

compound resistant to action of liquefied petroleum

gas.

8. The appliance and its individual shutoff valve must

be disconnected from the gas supply piping during

any pressure testing of that system at test pressures

in excess of 1/2 PSIG (3.45kpa).

9. The unit must be isolated from the gas supply

system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 PSIG (3.45kpa).

10. The appliance and its gas connection must be leak

tested before placing it in operation.

11. Purge all air from gas lines.

WARNING

Do not use open flame to check for leaks. An open

flame could lead to explosion, which could result in

property damage, serious injury or death.

NOTE: The Mighty Therm2 appliance and all other gas

appliances sharing the gas supply line must be firing at

maximum capacity to properly measure the inlet supply

pressure. The pressure can be measured at the supply

pressure port on the gas valve. Low gas pressure could

be an indication of an undersized gas meter, undersized

gas supply lines and/or an obstructed gas supply line.

Unit

20°F 25°F 30°F 35°F

Size

flow

H/L

flow

H/L

flow

H/L

flow

H/L

gpm feet gpm feet gpm feet gpm feet

500

43

1.7

34

1.1

28

0.9

24

0.7

750

64

3.3

51

2.3

43

1.7

36

1.2

1000

85

5.0

68

3.6

57

3.1

49

2.2

1250

106 8.1

85

6.1

71

4.7

61

3.4

1500

128 10.0 102 7.2

85

5.5

73

4.2

1750 N/R N/R 119 10.5 99

8.4

85

5.8

2000 N/R N/R 136 12.5 113 10.4 97

8.3

Metric Equivalent

Unit

11°C

14°C

17°C

19°C

Size

flow

H/L

flow

H/L

flow

H/L

flow

H/L

lpm m lpm m lpm m lpm m

500

161 0.5 129 0.3 107 0.3

92

0.2

750

241 1.0 193 0.7 161 0.5 138 0.4

1000

321 1.5 257 1.1 214 0.9 184 0.7

1250

401 2.5 322 1.9 269 1.4 231 1.0

1500

483 3.0 386 2.2 322 1.7 276 1.3

1750

N/R N/R 451 3.2 375 2.6 322 1.8

2000

N/R N/R 515 3.8 429 3.2 368 2.5

Notes: gpm = gallons per minute, lpm = liters per minute,

H/L = headloss, ft = headloss in feet, m = headloss in meters.

Maximum temperature rise is 35°F (19°C), as shown. Headloss is

for boiler’s heat exchanger only. N/R = not recommended.

Table 8. Water Flow Requirements — MT2H.

Figure 5. Typical Gas Train Configuration.