Pressure washer – Campbell Hausfeld IN469403AV User Manual

Page 14

14

Pressure Washer

www.chpower.com

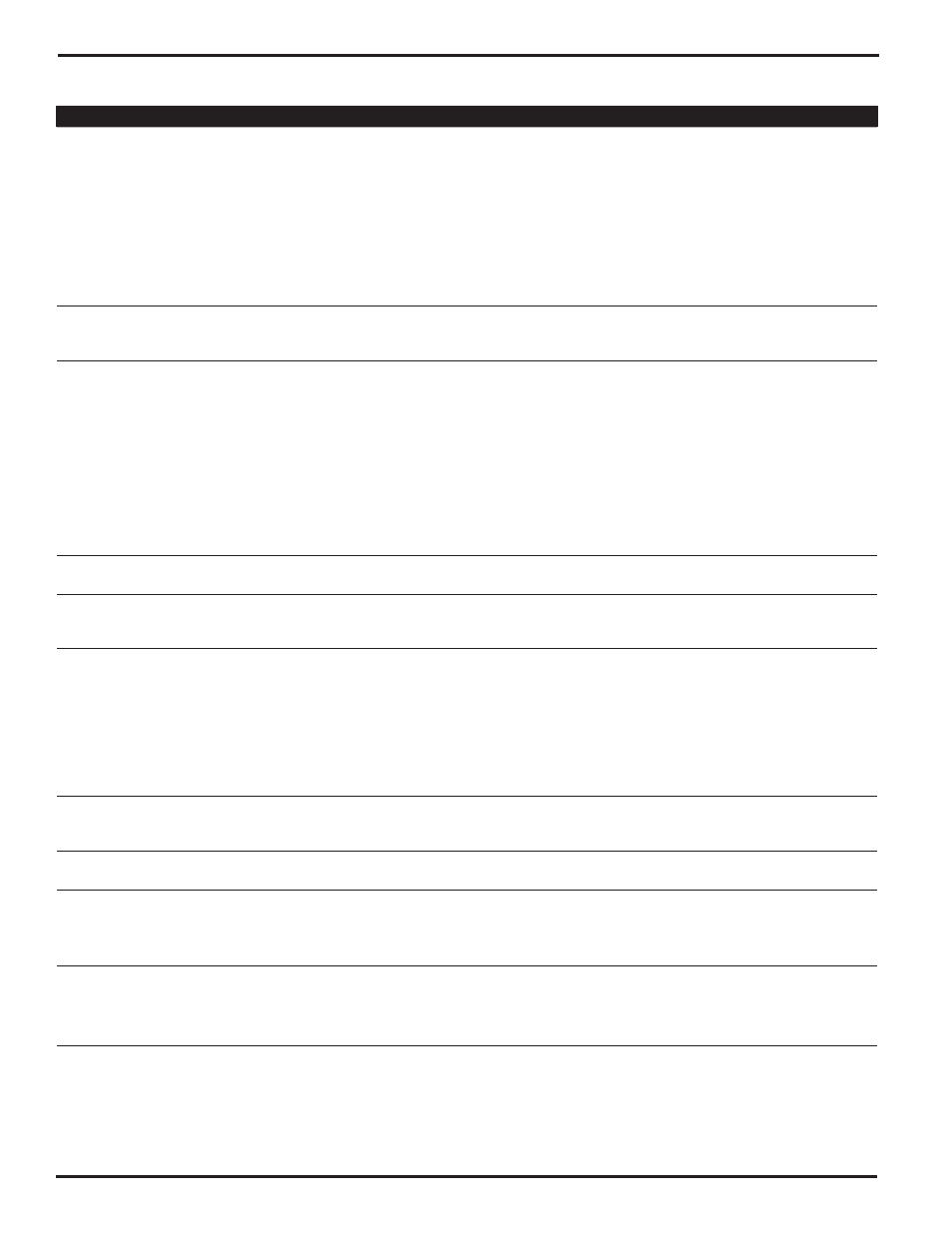

Troubleshooting Chart - Gasoline Powered Pressure Washers Only

Symptom

Possible Cause(s)

Corrective Action

Engine will not start or

is hard to start

1 . No gasoline in fuel tank or

carburetor

2 . Low oil

3 . Start/Stop switch in stop position

4 . Water in gasoline or old fuel

5 . Dirty air cleaner filter

6 . Spark plug dirty, wrong gap or

wrong type

7 . Spray gun closed

8 . Other causes

1 . Fill the tank with gasoline, open fuel shut off valve .

Check fuel line and carburetor

2 . Check oil level . Fill if necessary

3 . Move switch to start position

4 . Drain fuel tank and carburetor . Use new fuel and dry

spark plug

5 . Remove and clean or replace

6. Clean, adjust the gap, or replace

7 . Trigger spray gun

8 . See engine owner’s manual

Engine misses or lacks

power

1 . Partially plugged air cleaner filter

2 . Spark plug dirty, wrong gap or

wrong type

1 . Remove and clean or replace

2. Clean, adjust the gap, or replace

Low pressure and/or

pump runs rough

1 . Worn or wrong size tip

2 . Inlet filter on pump clogged

3 . Worn water seals, abrasives in

water, or natural wear

4 . Fouled or dirty inlet or discharge

valves

5 . Restricted inlet

6 . Worn inlet or discharge valves

7 . Leaking high pressure hose

8 . Pump drawing in air

9 . Unloader valve seat faulty or worn

1 . Replace with tip of proper size

2 . Clean . Check more frequently

3 . Check filter . Replace water seals . See service center

4 . Clean inlet and discharge valve assemblies . Check

filter

5 . Check garden hose, may be collapsed or kinked .

Check inlet water flow

6 . Replace worn valves

7 . Replace high pressure hose

8 . Ensure hoses and fittings are tight

9 . Check and replace

Water leakage from

under pump manifold

Worn water seals

Install new water seals . See service center

Water in pump

crankcase (milky oil)

1 . Humid air condensing inside

crankcase

2 . Oil seals leaking

1 . Change oil as specified in maintenance schedule

2 . Install new oil seals . See service center

Frequent or premature

failure of the pump

water seals

1 . Scored damaged or worn plungers

2 . Abrasive material in the fluid

3 . Inlet water temperature too high

4 . Overpressurizing pump

5 . Excessive pressure due to partially

plugged or damaged tip

6 . Pump running too long without

spraying

7 . Pump running dry

1 . Install new plungers . See service center

2 . Install proper filtration on pump inlet plumbing

3 . Check water temperature; may not exceed 100° F .

4. Do not modify any factory set adjustments.

5 . Clean or replace tip .

6 . Never run pump more than 2 minutes without

spraying

7 . Do not run pump without water

Strong surging at the

inlet and low pressure

Foreign particles in the inlet or

discharge valve or worn inlet and/or

discharge valves

Clean or replace valves . See service center

Oil leakage between the

engine and the pump

Worn oil seals and/or o-ring

Replace oil seals and/or o-ring . See service center

Fluctuating pressure

1 . Valve worn, dirty or stuck

2 . Pump drawing in air

3 . Tip clogged

1 . Check and replace

2 . Ensure hoses and fittings are tight . Purge air from

garden hose

3 . Check or replace

Pressure drops after

period of normal use

1 . Worn pump water seals

2 . Nozzle worn

3 . Valve worn, dirty or stuck

4 . Unloader valve seat worn or dirty

1 . Check and replace

2 . Check and replace

3 . Check, clean or replace

4 . Check, clean or replace

Pump noisy / pump runs

rough

1 . Pump drawing in air/low water

supply

2 . Valves dirty or worn

3 . Worn bearings

4 . Water too hot

1 . Ensure fittings are tight . Increase water pressure

2 . Check, clean or replace

3 . Check and replace

4 . Reduce temperature below 100° F