Recommended lubrication and frequency – I.C.E. GIDM-325 User Manual

Page 11

10

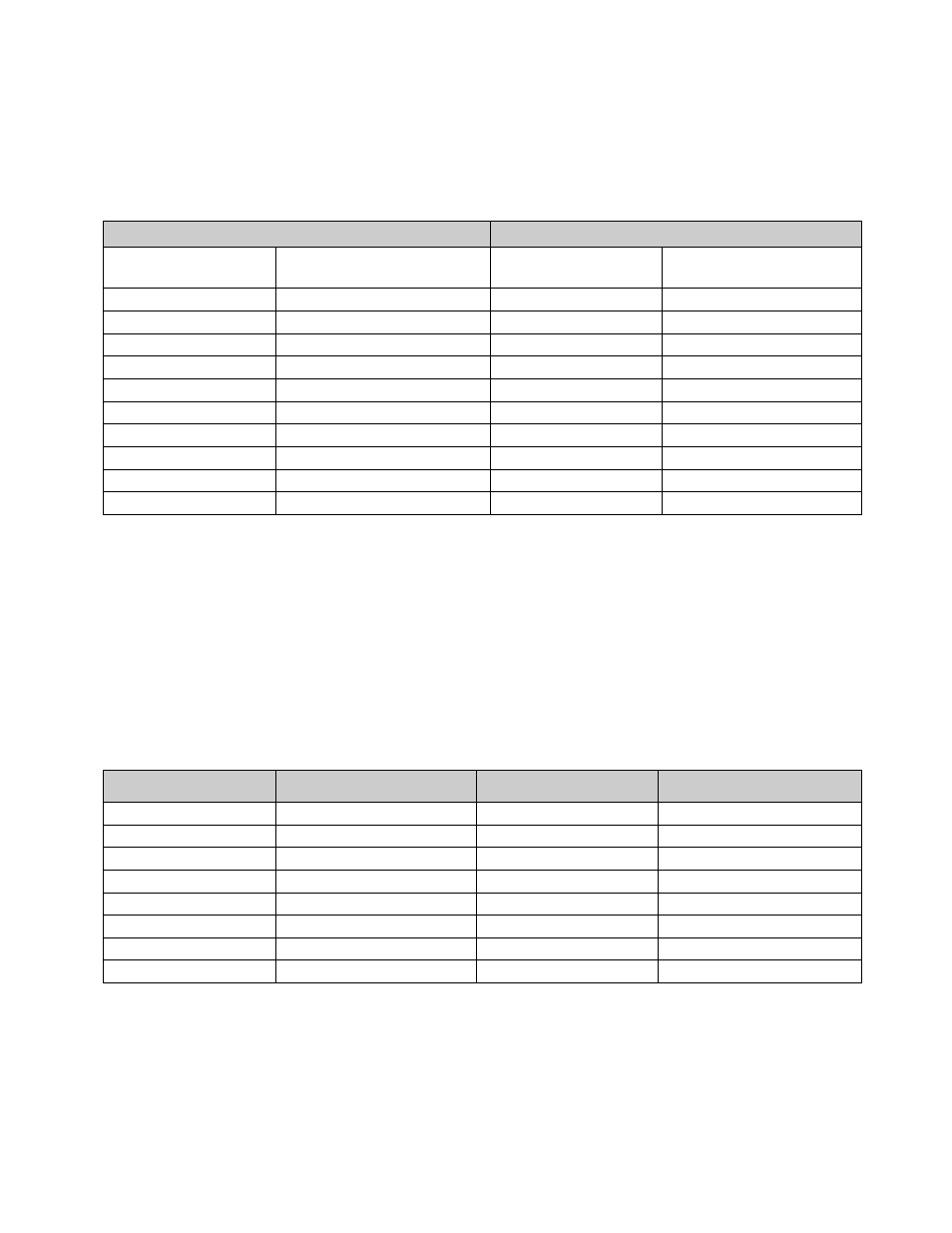

Table 1. Recommended Lubrication

Ball Bearings

Roller Bearings

Shaft Size

(inches)

Grease Charge

(ounces)

Shaft Size

(inches)

Grease Charge

(ounces)

1/4 to 3/16

0.03

1-3/16 to 1-1/4

0.1

1/2 to 3/4

0.1

1-3/8 to 1-7/16

0.22

1-1/4 to 1-1/2

0.15

1-1/2 to 1-11/16

0.32

1-11/16 to 1-15/16

0.2

1-3/4 to 2

0.5

2 to 2-7/16

0.3

2 to 2-3/16

0.55

2-1/2 to 2-15/16

0.5

2-1/4 to 2-1/2

0.65

3 to 3-7/16

0.85

2-11/16 to 3

0.85

3-1/2 to 4

1.5

3-3/16 to 3-1/2

1.25

-

-

3-15/16 to 4

2.5

-

-

4-7/16 to 4-1/2

3.1

Frequency of re-lubrication depends upon operating conditions. The bearing operating temperature is the best index

for determining a re-lubrication schedule. The following chart gives the frequency of re-lubrication based upon

continuous operation for various operating temperatures and can be used as a satisfactory guide for determining

when bearings should be re-lubricated.

Table 2. Lubrication Frequency

Speed

Temperature

Cleanliness

Greasing Interval

100 RPM

Up to 120 F

Clean

5 months

500 RPM

Up to 130 F

Clean

2 months

1000 RPM

Up to 210 F

Clean

2 weeks

1500 RPM

Over 150 F

Clean

Weekly

Any speed

Up to 150 F

Dirty

1 week to 1 month

Any speed

Over 150 F

Dirty

Daily to 1 week

Any speed

Any temperature

Very dirty

Daily to 1 week

Any speed

Any temperature

Extreme conditions

Daily to 1 week