Great Planes SpaceWalker ARF - GPMA1300 User Manual

Page 13

❏

5. If you installed a 2-stroke engine on your plane, install

the muffler and bend the throttle pushrod as needed to

avoid interference between the muffler.

❏

6. Switch your radio system on. Check that the throttle

opens and closes completely using the throttle stick and

trim on the transmitter. (See your radio instruction manual

for proper adjustment.) When satisfied with the operation of

the throttle, permanently attach the pushrod connector to

the servo arm with the plastic retainer and tighten the cap

screw onto the pushrod. Cut off the excess pushrod.

❏

7. Glue the throttle outer pushrod tube to the formers to

secure it in position.

❏

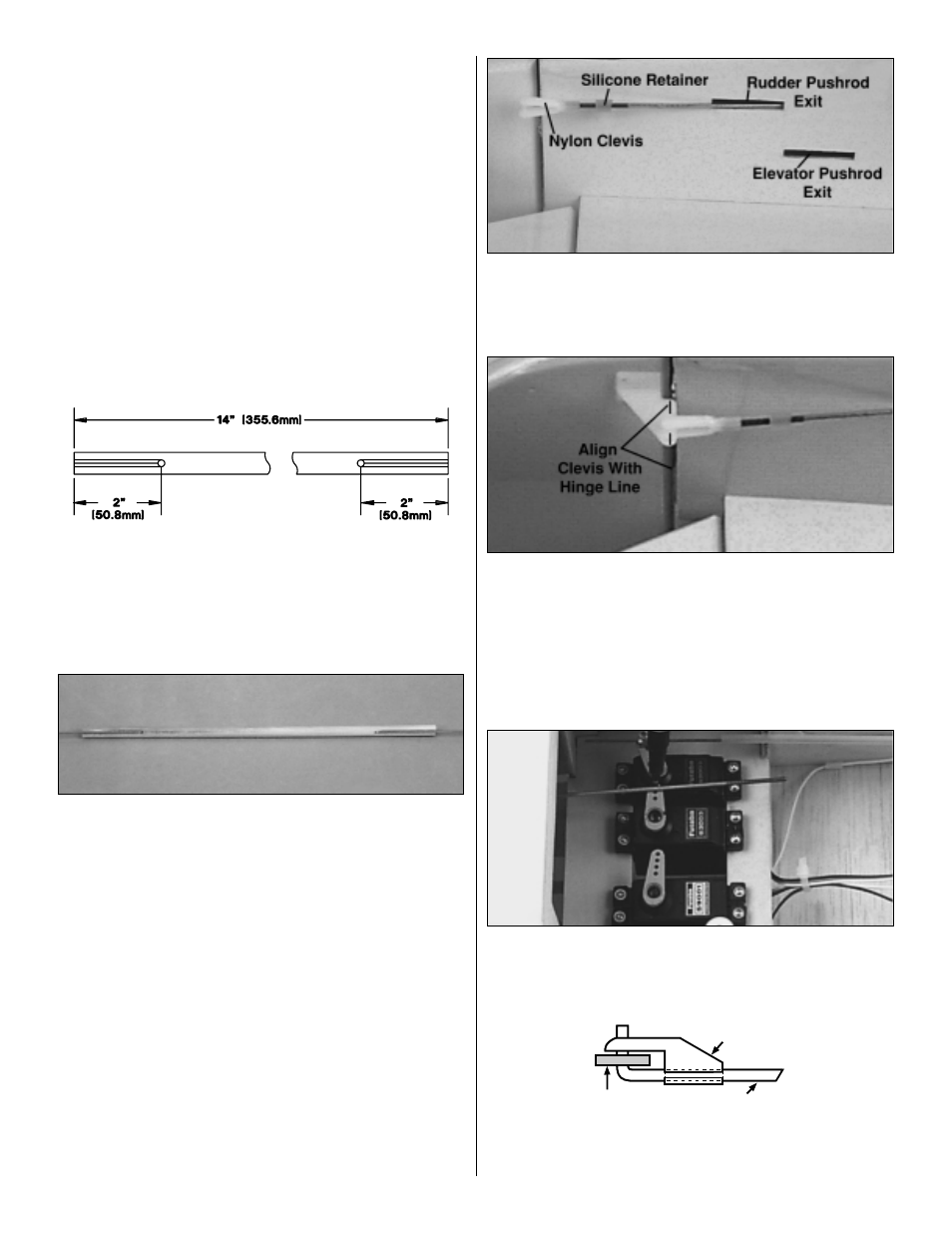

8. Cut both wood dowels to 14" [355.6mm] long.

❏

9. In one of the wood dowels, drill 5/64" [2mm] holes

through the dowel, 2" [50.8mm] from each end. On each

end of the dowel, use a hobby knife to cut a groove from

the hole to the end of the dowel, deep enough for a 2-56

threaded pushrod to fit in.

❏

10. From the threaded end of a 2-56 x36" pushrod, cut

an 11" [279.4mm] long piece. Cut a second non-threaded

11" [279.4mm] piece from the same 36" pushrod. Make a

90° bend 1/4" [6.4mm] from the non-threaded end of both

11" pushrods. Insert the “bent end” of the wire into the

holes in the wood dowel.

❏

11. Cut the 8" [203mm] shrink tubing into four 2" [50.8mm]

pieces. Slide a 2" [50.8mm] piece over each end of the

wood dowel and pushrod. Use a heat gun to shrink the

tubing tight around the dowel. Apply several drops of thin

CA to each end of the shrink tubing to secure it to the

dowel. This is now the rudder pushrod.

❏

12. Trim the covering from the two elevator pushrod

exits and the rudder pushrod exit at the aft end of the

fuselage. Apply a small amount of thin CA around the exits

to fuelproof them.

❏

13. Insert the rudder pushrod into the fuselage with the

threaded rod exiting out the rudder exit slot. Slide a silicone

clevis retainer over the rudder pushrod and screw a nylon

clevis 14 turns onto the rudder pushrod.

❏

14. Attach a control horn to the clevis. Align the clevis

holes in the control horn with the hinge line of the rudder.

Mark the control horn mounting holes.

❏

15. Drill a 3/32" [2.4mm] hole at both marks. Mount the

rudder control horn to the rudder with the backing plate and

two 2-56 x 5/8" machine screws. Slide the silicone retainer

over the clevis to secure it in place.

❏

16. With the servos centered and the rudder in the

neutral position, use a felt-tip pen to mark where the

pushrods cross the mounting holes in the servo arms.

❏

17. Make a 90° bend at the mark you made. Insert the

rudder pushrod in the rudder servo horn and secure it with

FasLink

2-56 (.074") Pushrod Wire

Servo Horn

13