Great Planes Cessna 182 Skylane 40 ARF - GPMA1228 User Manual

Page 8

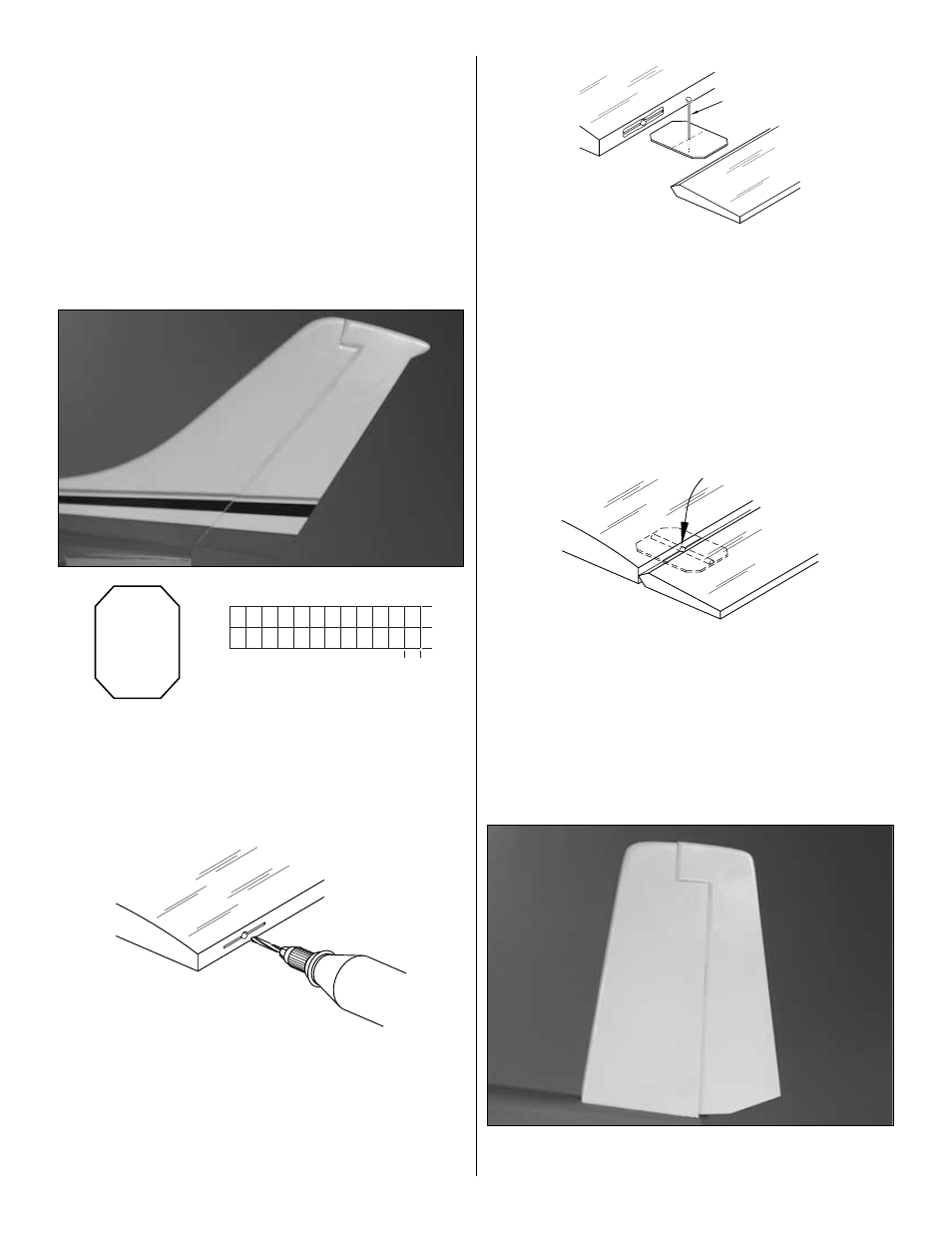

along both the sides of the fin where it meets the fuselage

and remove the covering 1/32" [.8mm] inside the line, being

careful not to cut into the underlying wood. Sand the bottom

of the fin and the slot in the fuselage if the fin is out of

alignment. Do not force the forward section of the fin into

position, as this will result in poor flight characteristics. Use

30-minute epoxy to glue the fin in position. Work the epoxy

into the slot in the fuselage, filling any loose-fitting joints

between the fuselage and stabilizer. Check the alignment of

the fin to the stabilizer with a triangle, then secure it in

position with masking tape until the epoxy has cured.

Double-check the alignment of the fin with the stabilizer

while the epoxy cures.

❏

5. Test fit the rudder to the fin with the hinges. If the

hinges are difficult to install or don’t go in far enough,

carefully enlarge the hinge slots with a hobby knife and a

#11 blade. (Cut the hinges to the size shown above from the

2" x 9" [51mm x 229mm] hinge material.) Use the following

procedure for gluing the hinges and tail gear assembly:

❏

A. Drill a 3/32" [2.5mm] hole, 1/2" [13mm] deep, in the

center of the hinge slot. If you use a Dremel

®

MultiPro

™

for

this task, it will result in a cleaner hole than if you use a

slower speed drill. Drilling the hole will twist some of the

wood fibers into the slot, making it difficult to insert the

hinge, so you should reinsert the knife blade, working it back

and forth a few times to clean out the slot.

❏

B. If the hinges don’t remain centered, remove the rudder

and insert a pin in the center of the hinges. Make sure there

is approximately a 1/64" [.4mm] gap between the rudder and

the fin.

❏

C. Add six drops of thin CA to the center of the hinges on

both sides. Use a paper towel to absorb excess CA from the

hinge gap before it cures. Do not use CA accelerator; allow

the CA to cure slowly.

❏

6. Use the same hinging method to join the Elevators to

the stab.

ASSEMBLE, THEN APPLY 6 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

TEMPORARY PIN

TO KEEP HINGE

CENTERED

DRILL A 3/32" [2.5mm] HOLE

1/2" [13mm] DEEP, IN CENTER

OF HINGE SLOT

1"

[25mm]

1"

[25mm]

3/4"

[19mm]

8