Wing assembly – Great Planes Cessna 182 Skylane 40 ARF - GPMA1228 User Manual

Page 6

❏

1. Mark the ailerons left and right and remove them from

the wing panels. Remove the covering from the aileron

servo openings on the bottom of the wing only. Cut 1/8"

[3mm] inside of the opening to allow some material to be

ironed down inside the opening. Use a sealing iron to secure

the covering around the openings.

❏

2. Locate the pre-installed strings in the wing center-

section and wing outer panels. When attaching the wing

outer panels to the wing center-section, the strings for

installing the aileron servos must be moved so they do not

interfere with the fit of the panels. Don’t remove the string

because you will use it to pull your aileron servo cords

through the wing later. Tape each of the strings located in

the aileron servo openings in the outer tip panels to the

bottom of the wing.

❏

3. Locate the hardwood wing joiners. Test fit the wing

joiner into the right wing panel and the right side of the wing

center-section. The joiner is positioned so 1/3 is in the wing

center-section, and 2/3 is in the tip panel. A snug fit of the

joiner is desirable. If the joiner does not fit properly, lightly

sand any uneven surfaces of the joiner edges and sides.

Repeat this step to check the fit of the other wing joiner in

the left wing panel. Label each wing joiner for orientation

and the side that it is to be used on.

❏

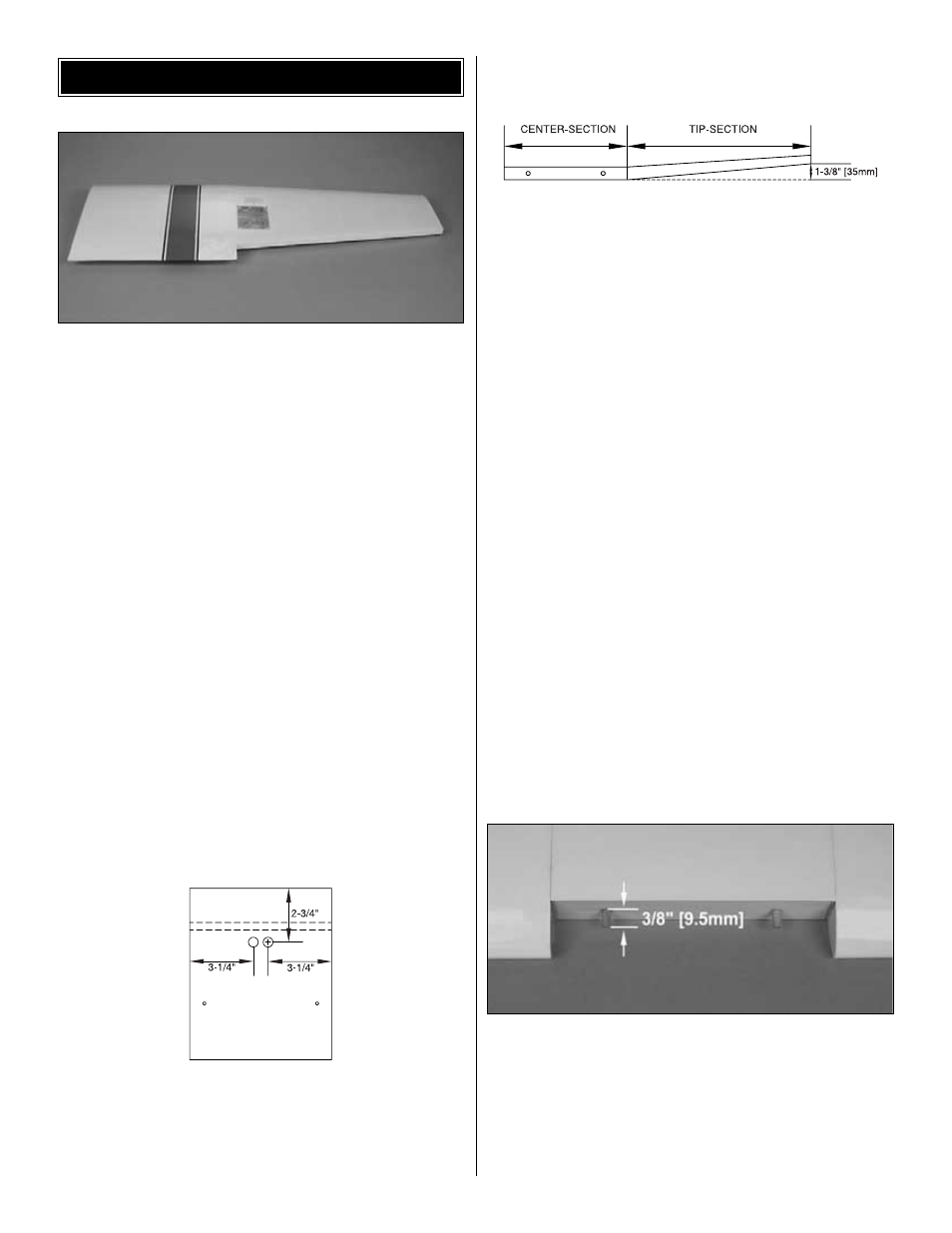

4. Drill two 1/2" [13mm] holes in the BOTTOM of the wing

center-section as shown in the drawing. The servo leads will

exit from these holes. The holes are located 2-3/4" [70mm]

back from the front of the wing center-section and 3-1/4"

[83mm] from the edges.

Make a dry run of the following step without using any glue

so you will know how to join your wing together, then

proceed using glue.

❏

5. Un-tape the pre-installed strings in the wing center-

section and the right wing outer panel. Tie the strings

together, being careful not to pull the strings out of the

panels. Note: Don’t remove the strings because you will use

them to pull your aileron servo cords through the wing later.

Tape a piece of wax paper or plan protector over your work

surface. Use a liberal amount of 30-minute epoxy to glue the

wing joiner into the right wing panel and wing center-section.

Apply epoxy to all sides of the joiner, joiner pockets, and

center ribs of both the right wing panel and wing center-

section. Join the wing panel and wing center-section. Use

masking tape to tightly tape the right wing panel and wing

center-section together. Be certain the leading and trailing

edges align. If you have used enough epoxy, it will “ooze”

out from the joint between the two ribs. Wipe off any excess

epoxy from the outside of the wing with a paper towel and

rubbing alcohol. With the wing center-section upright and

flat on your building surface, measure the distance from

your work surface to the tip of the wing outer panel to make

sure you have the correct amount of dihedral as shown in

the sketch. After the epoxy has cured, repeat this step to join

the left wing panel to the wing center-section.

❏

6. Locate the two 1/4" x 2-1/8" [6mm x 54mm] hardwood

wing dowels. Slightly bevel the ends of the dowels. Test fit

the dowels into the wing, making sure they lock into the

holes inside the wing. If necessary, clean out the holes in the

wing using a 1/4" [6mm] drill bit. Use 30-minute epoxy to

glue the dowels into the wing, letting them protrude

3/8" [9.5mm]. Wipe off any excess epoxy using a paper

towel and rubbing alcohol.

WING ASSEMBLY

6