Great Planes Cessna 182 Skylane 40 ARF - GPMA1228 User Manual

Page 14

❏

14. Cut a slot in the left side of the fuselage for the rudder

pushrod tube to exit the fuselage.

❏

15. Use a 3/16" [5mm] drill bit or a sharpened 3/16" [5mm]

brass tube to chamfer the holes for easier installation of the

pushrod tube.

❏

16. Locate a 36" [914mm] outer pushrod guide tube and

scuff the outside with coarse grit sandpaper. Route the tube

through the fuselage and into the radio compartment. The tube

must protrude at least 1/2" [13mm] from the fuse side exits.

Glue the tube to the fuselage using medium CA.

❏

17. Insert one of the 2-56 x 36" threaded end rods into the

rudder tube in the fuselage. The pushrod should slide easily

into the tube. Thread a nylon clevis on the pushrod 14-turns

and add a silicone retainer to the clevis.

❏

18. Install the rudder nylon control horn in line with the

pushrod. Hold the horn in position and mark the location of

the mounting holes. Drill 3/32" [2.5mm] mounting holes

through the marks. Wick two to three drops of thin CA into

the holes to harden the underlying balsa, then re-drill the

holes. Attach the horn using two 2-56 x 5/8" machine screws

and a nylon nut plate. Do not overtighten the screws,

crushing the underlying balsa.

❏

19. Center the rudder and rudder servo and mark the

pushrod where it crosses the servo arm. Enlarge the servo

horn hole with a 5/64" [2mm] drill bit.

❏

20. Make a 90º bend in the pushrod on your mark, then

insert it through the enlarged hole in the servo arm. Secure

the wire in place with a nylon FasLink pushrod keeper. Trim

the excess wire protruding from the FasLink.

❏

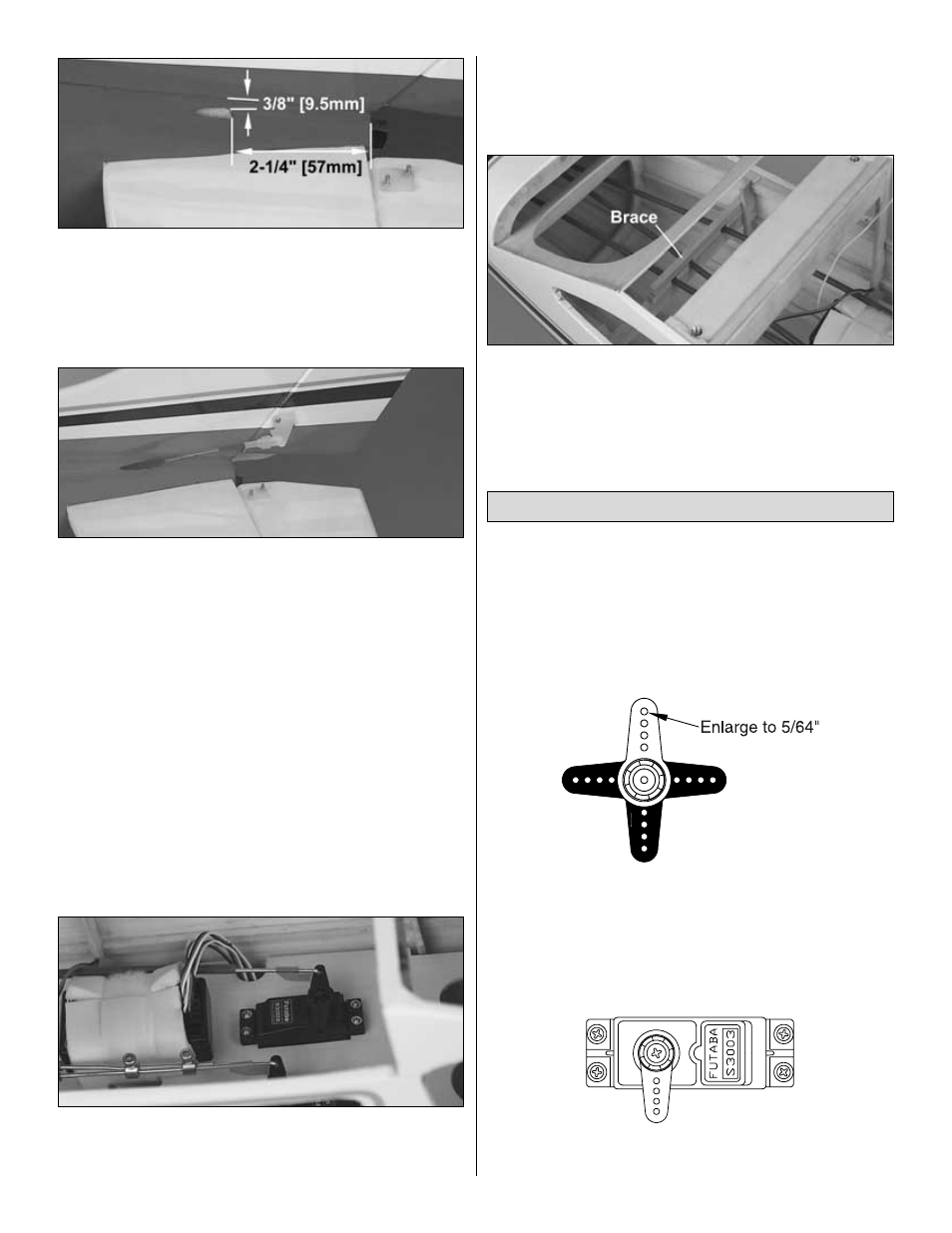

21. Once the rudder and elevator pushrods have been

installed, a brace must be constructed to support the

pushrods near the servo. Use balsa or mixing sticks to make

the brace (not included). Position the brace so the pushrods

will not bind when the controls are operated. Secure the

brace using medium CA.

Prepare two “cross” style servo horns as follows but don’t

install them on the servos until instructed to do so.

Note: The size and shape of servo horns varies from

manufacturer to manufacturer. The sketches and photos

show a typical radio installation with standard servo horns.

All standard servo horns should fit in the Cessna 182.

❏

A. Cut off three arms from two servo horns included with

your radio control set to make them into “one arm” servo

horns. Use your Bar Sander to remove the remaining jagged

edges left from the cut-off arms.

❏

B. Enlarge the holes in the horns with a 5/64" [2mm] drill.

❏

C. Connect the aileron servos to the receiver. Turn on your

transmitter and receiver, then position the aileron trim tabs

Aileron Servo Installation

14