Changing friction wheel – Cub Cadet 945 SWE User Manual

Page 20

NOTE:

Make sure to remove the piece of wood blocking the

impeller.

Check the auger drive belt adjustment. With the auger

clutch lever in the disengaged position, the top surface of

the new belt should be even with the outside diameter of

the pulley.

To adjust, disconnect ferrule from brake bracket assembly.

Thread ferrule in (towards idler) to increase tension on belt,

or out to decrease belt tension.

NOTE:

The brake puck must always be firmly seated in the

pulley groove when auger control is disengaged.

CAUTION:

Repeat the “Testing Auger Drive

Control” from the Assembly & Set-up section

before operating the snow thrower.

Drive Belt Replacement

If not already done, remove the auger drive belt from the

front pulley of the engine double pulley. Refer to “Auger

Belt Replacement” instructions in the previous sub-section.

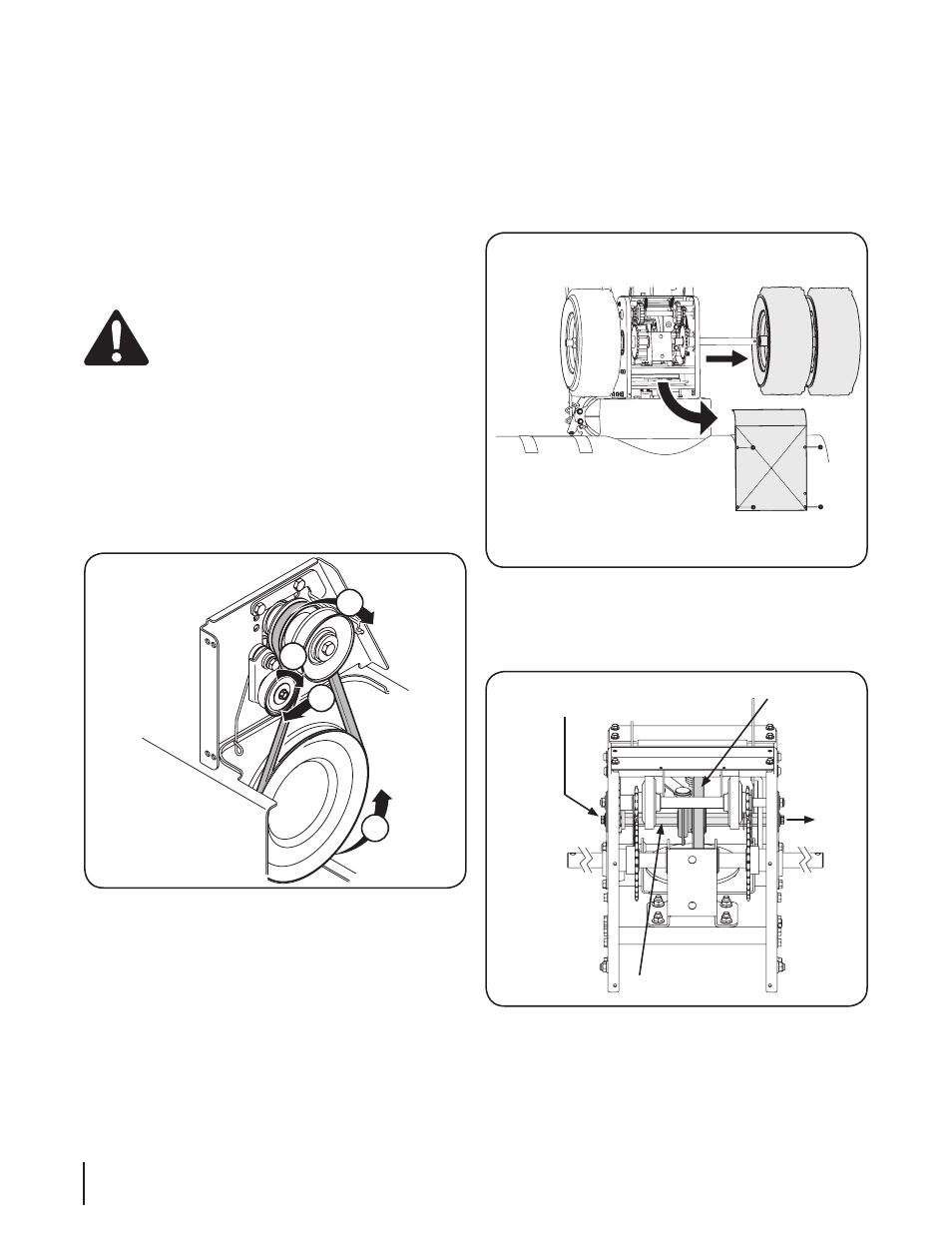

1. Use a wrench to rotate the idler pulley away from the

backside of the drive belt to relieve the tension and slip

the drive belt off the idler pulley. Carefully release the

idler pulley. See Fig. 7-8.

2. Roll the drive belt off the lower drive pulley and then

remove the belt from the engine pulley.

3. Install the new belt on the engine pulley, then seat around the

lower drive pulley and re-tension with the idler pulley.

4. Reassemble by performing the previous steps in the

opposite order and manner of removal.

Changing Friction Wheel

The rubber on the friction wheel is subject to wear and

should be checked after the first 25 hours of operation,

and periodically thereafter. Replace the friction wheel if

any signs of wear or cracking are found.

1. Drain the gasoline from the snow thrower, or place a

piece of plastic under the gas cap.

2. Tip the snow thrower up and forward, so that it rests on

the housing.

3. Remove screws from the frame cover underneath

the snow thrower (refer to Fig. 7-9). Remove the right

wheels from the axle.

4. Using a 3/4” wrench, hold the hex shaft and remove the

hex screw and belleville washer and bearing from left

side of the frame. Refer to Fig. 7-10.

5. Holding the friction wheel assembly, slide the hex shaft

out of the right side of the frame. The spacer on the left

side of the hex shaft will fall and the sprocket should

remain hanging lose in the chain.

Figure 7-8

2

3

1a

1b

Figure 7-9

Figure 7-10

Friction Wheel Assembly

Hex Shaft

Remove Hex Screw &

Belleville Washer

Slide Hex

Shaft Out

Right Side

20

S

ection

7 — S

ervice