Line trimming, Material stress – GIN Boomerang 10 User Manual

Page 32

Boomerang 10

32 / 62

Line trimming

The Boomerang 10 is trimmed to give the highest possible level of performance and safety. The

aramid lines may shrink or stretch in normal use and particularly after hard shock-reinflations.

Pilots should check that the lines remain within tolerance. The Boomerang 10 is certified with

the lines trimmed so that the total line length from tab to riser is within 2cm of the values

stated in the line-plan. The lines must be measured with a load of 5kg, in order to ensure

reproducible results for a comparison with the lengths in the check sheets.

Due to different measuring systems and calibration there is a possibility of a difference in the

absolute line lengths. In this case, the measured values should first be corrected to the same

base of the Boomerang 10 check sheet data. Correct line length and symmetry are important for

performance, handling and have a considerable influence on flight behavior.

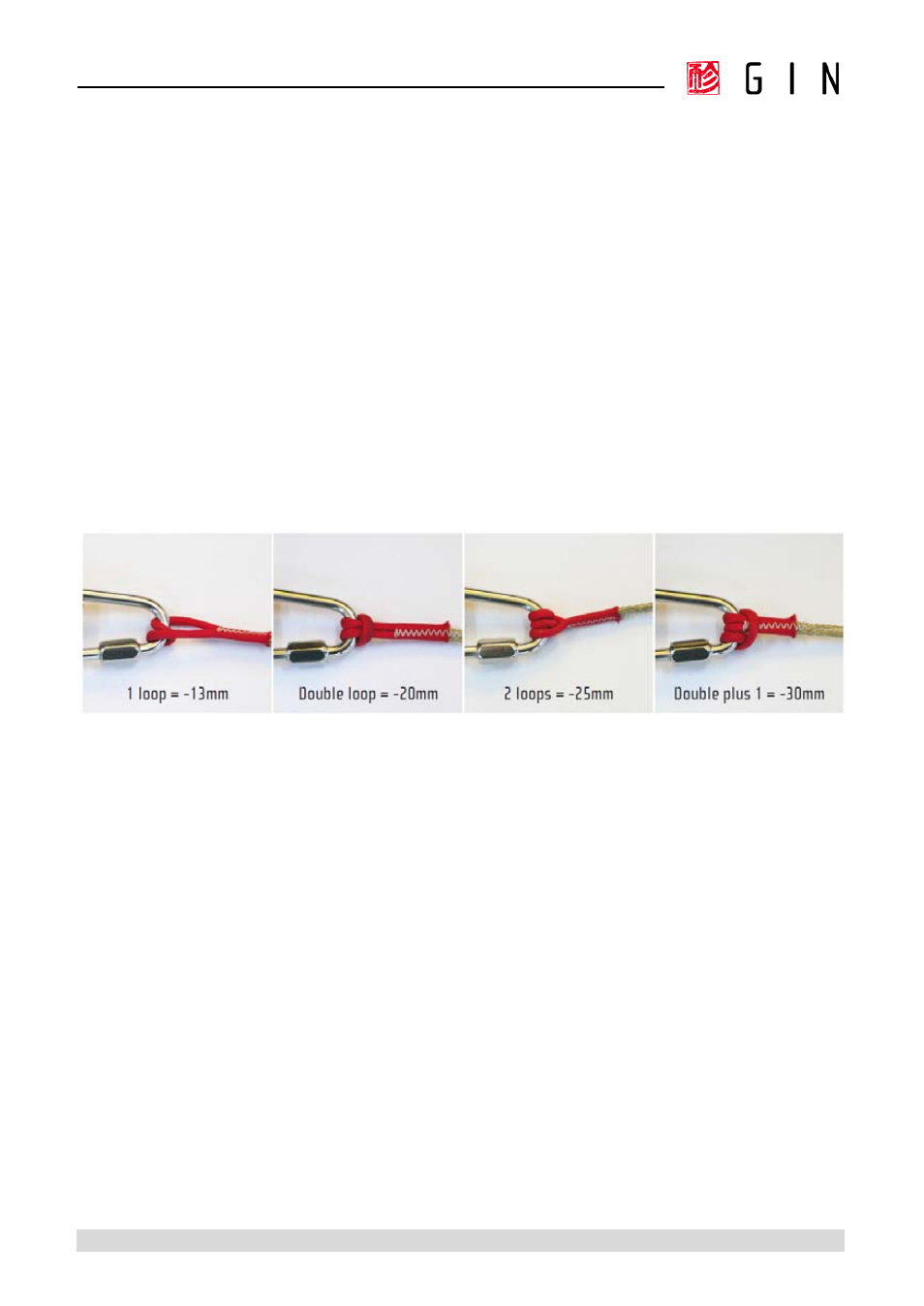

If the lines are more than 2cm out of tolerance they should be replaced. If the lines are less

than 2cm out of tolerance they can be re-trimmed either by taking (or releasing) loops on the

Maillons or by adding an extended Maillon. Contact your dealer or Gin Gliders for details of how

to retrim your glider.

Fig. 4: Allowed loops on Maillons

WARNING Do not under any circumstances use knots to shorten the lines. Any knot will weaken

the line considerably and may cause the line to break in case of high load. The

overhand knot and bowline knots described are permitted only for connecting the

main brake lines/brake handle.

Lines age and lose strength even if the paraglider is used infrequently or not at all. This can

affect the safety and function of your paraglider. Signs of wear are slight bumps or changes in

flying characteristics. The lines must then be replaced immediately. Use only inspected and

approved lines, which can be obtained through Gin Gliders.

A damaged line can result in loss of control of the glider. Always replace lines which are

damaged.

Material stress

Uncontrolled flight positions—such as may be encountered during safety training, extreme

manoeuvres or after massive collapses or cascades—are outside the manufacturer limits of the

paraglider. This may cause a general deterioration in flight characteristics, premature ageing,

or even structural failure.