Lift off protection, Overload protection – Flintec 52-18SS User Manual

Page 7

7

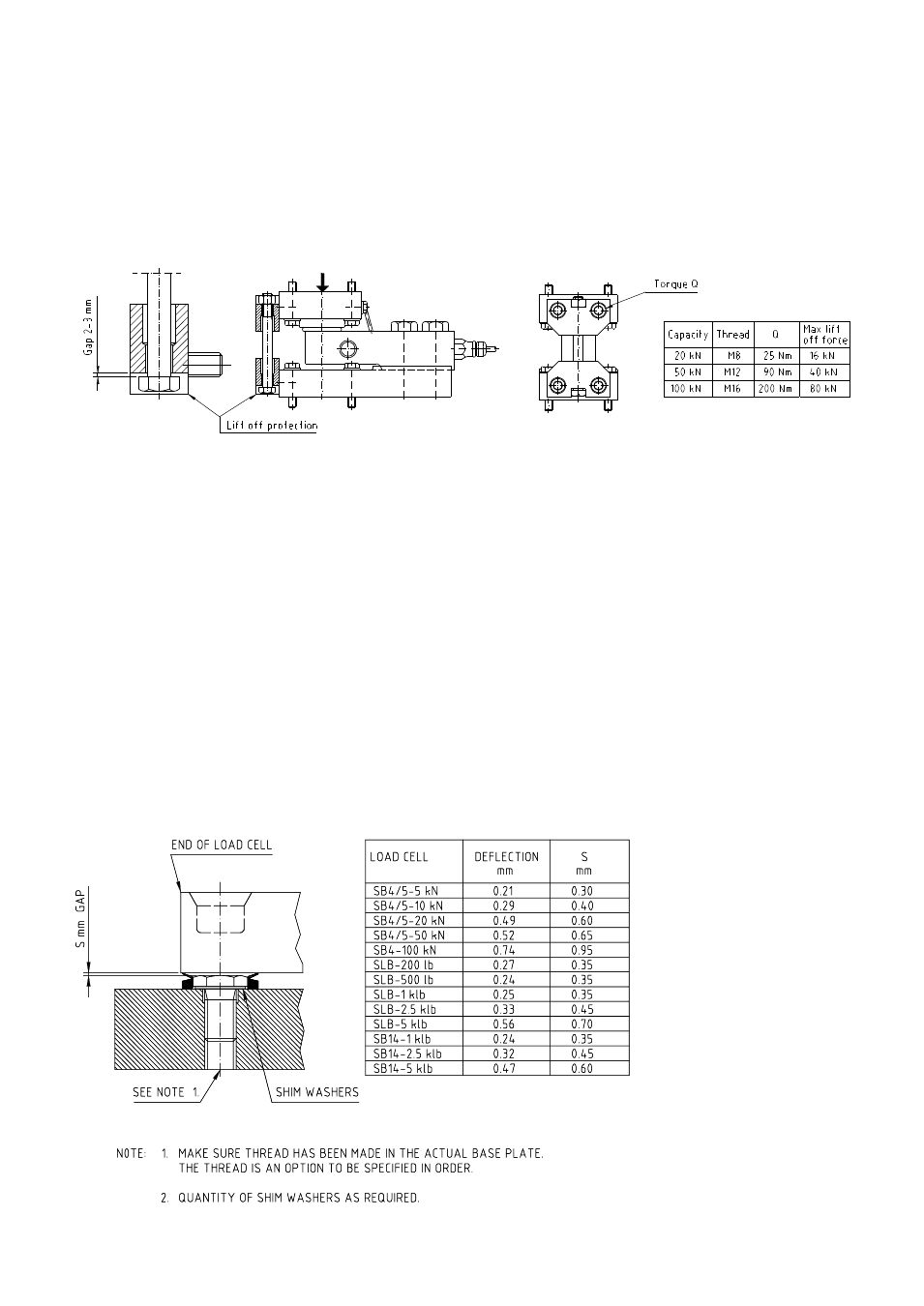

Lift off protection.

An optional lift off protection can be fitted after the installation of the weigh module. It utilizes the same holes

which, before installation, were used with the alignment plate to hold the module together.

In most indoor applications the tanks or hoppers never see any wind forces or other side forces, which could

cause lift off. Lift off protection should therefore only be added when required.

The lift off bolt has large clearance to the upper and lower brackets which allows the rocking or sliding motion of

the module without interference. The lift off gap can be set by rotating the nut on the screw prior to mounting.

Figure 12.

Overload protection

As yet another option, the weigh modules can be fitted with an overload stop, which protects the load cell in case

of an overload. The overload stop is simply the head of a hex head screw, which stops the down movement of the

loading end of the cell. Thanks to the relatively large deflection of the shear beam, the gap between the cell and

the screw head is easy to set by inserting shim washers under the head. The table below shows recommended

gaps which are selected to be ca 30 – 40 % more than the deflection of the cell at nominal load. The actual gap

can be measured by using a feeler guage. If the load cell is to be utilized to less than nominal load, the gap can

preferably be reduced in proportion. With overload stop fitted, the cell will be protected to at least 5 times

nominal load.

A rubber V-ring prevents dirt from entering the gap.

Figure 13.