Installation – Flintec 52-18SS User Manual

Page 10

10

Installation

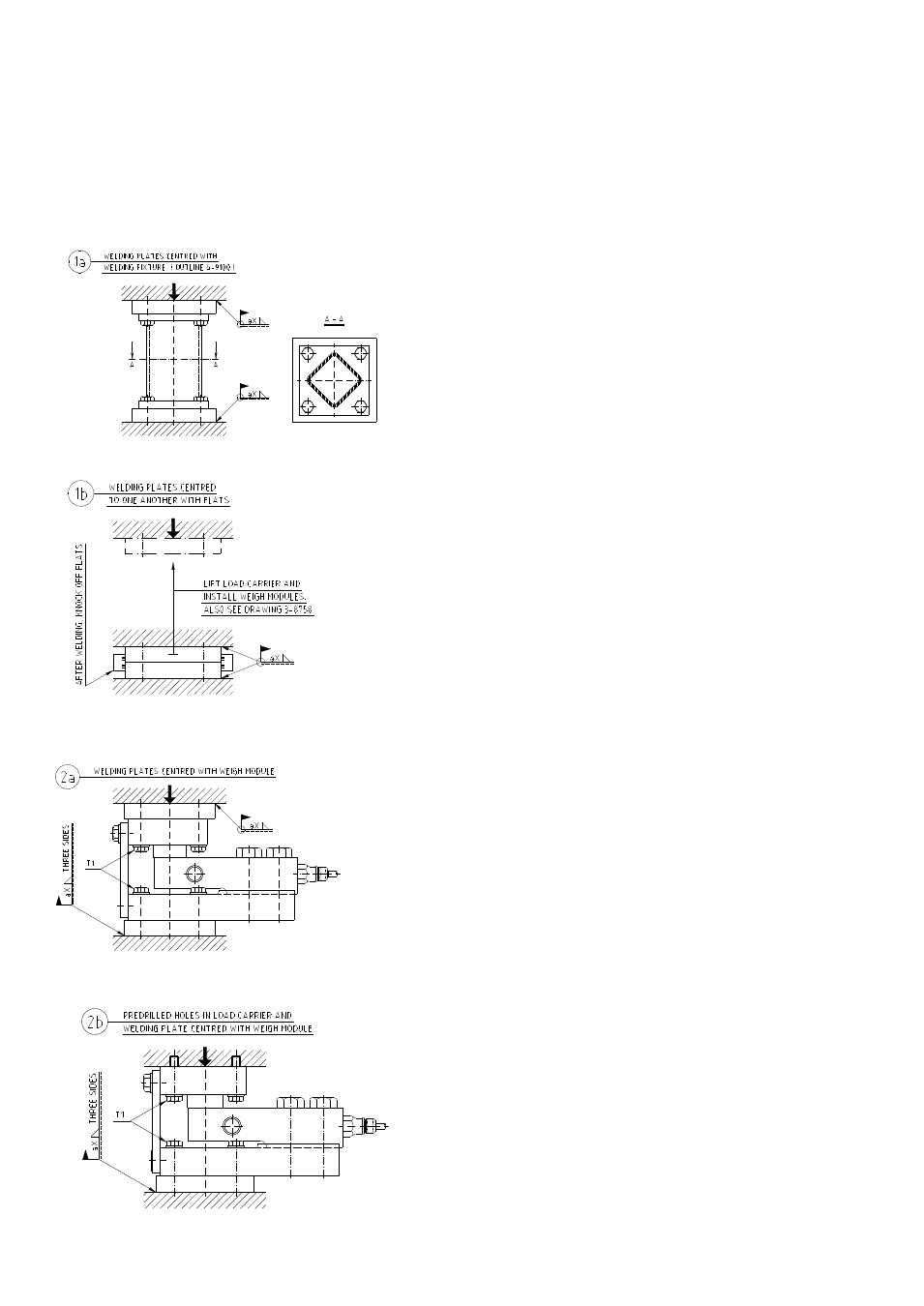

A large number of installation methods are available.

For large tanks and hoppers it is usually impossible to position mounting holes in load carrier resp. in the

foundation structure accurately enough to allow insertion of all mounting screws. The use of Welding Plates or

Bolting Plates, the latter having pre drilled extra large mounting holes, are therefore convenient methods to solve

this problem. Some of these alternatives are shown below.

-Figure 1a shows how welding plates on top and on bottom can be

accurately installed using a welding fixture.

-Figure 1b shows how same welding plates can be accurately installed

without the use of a welding fixture.

The welding plates, in this case, are delivered centered to one another with

a pair of “knock-off flats”. A requirement for this alternative is that the

load carrier can be lowered down deep enough to apply tack welds to hold

each of the plates in position. When this has been done, the flats are to be

knocked off, load carrier lifted and welding finalized.

Enclosure 3-8758 describes this method more in detail.

-Figure 2a shows a case where the weigh module itself acts as a fixture

for holding the welding plates in position.

Note that the welding plates are slightly bigger than the top resp. the

bottom plates. This makes it easy to hold a piece of sheet metal against

the welding plate to protect the weigh module from weld splashes.

When welding, make sure that the ground cable of the welding machine

is connected to the same side at which the welding is done, so that no

current flows through the load cell. Load cell cable should preferably

not be connected in the summing box during welding.

-Figure 2b illustrates a case where the load carrier has been

prepared with mounting holes from factory.

The weigh module holds the welding plate in position against the

foundation, ready for welding.

This method opens the possibility of pre-installing the modules to

the load carrier in the factory and deliver, ready for the final

welding operation on site. Cables, summing boxes etc. can in this

case preferably also be pre installed “on board” the load carrier.