Maintenance instructions – EDCO SK-10 User Manual

Page 8

E-MPS-I-0612

Printed in USA

©2012

TVW

Page 8

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

Disconnect the machine from the power source. Remove the spark plug lead on gasoline engine models

or disconnect the supply voltage connector on electric models, before performing any maintenance. All

maintenance to be performed regularly by qualified personnel.

•

Never work under saw without first placing chocks on the wheels and support device under the saw to prevent it

from moving or falling. Always work on a flat and level surface.

•

Refer to the engine manual for maintenance information specific to the engine used. Be sure to check oil level

before operation. Clean air filter element daily.

•

Grease bearings after every 4 hours of use. Refer to

(page 10)

for lubrication points on available models.

•

Perform a visual inspection of the entire machine before operation. Be sure all fasteners are tight and secure,

check for signs of metal cracking or fatigue, inspect for damage to electrical wiring, damage to fuel lines, check

bearings and inspect to be sure proper guards are in place and secure, etc...

•

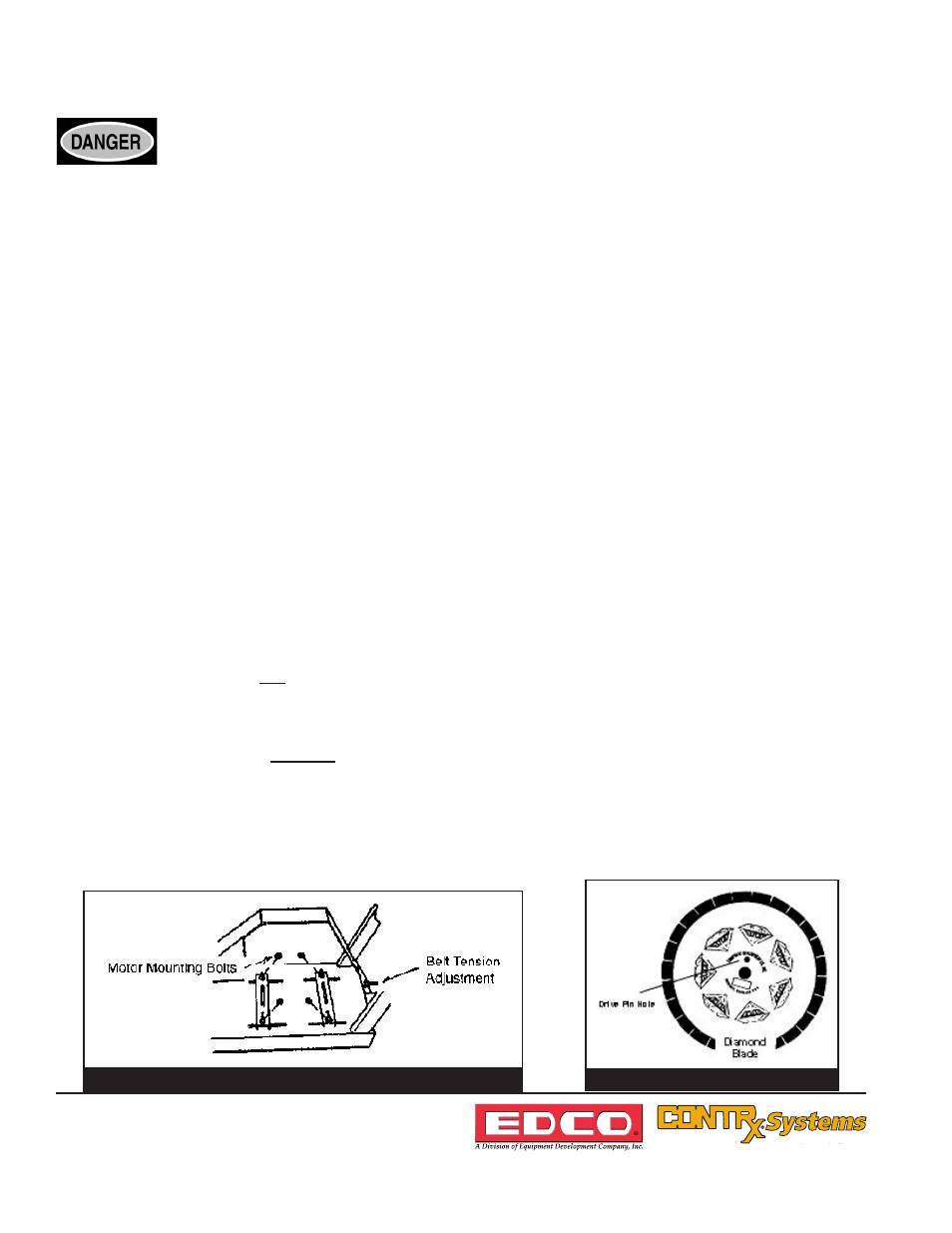

Inspect belts before operation. Check belt tension. On new equipment, belts should be re-tensioned after the first

four hours of use. Damaged, stretched or excessively worn belts should be replaced with a new matched set.

•

To tension belts, loosen motor mounting hardware slightly. Either push motor towards the rear of the saw (handle

bar side) until the belts are tight or on the models with a belt tensioning adjustment bolt, use bolt to adjust the mo-

tor until the belts are tight. Re-torque the engine mounting hardware

(see

Figure 8

below).

•

Proper belt tension must be maintained to transmit the engine power to the cutting blade. Slipping belts will over-

heat, the blade life will be shortened and the cutting speed limited. Over tensioned belts will shorten the belt and

bearing life.

•

Check diamond blades for cracks, loose segments and oversize, worn, or out-of-round arbor holes

(See Figure 5

on page 5)

. Do not use

any questionable blade since serious injury and/or damage to property can result. Do

not use warped, twisted, or out-of-balance blades. Unbalanced blades will wear excessively, vibrate and damage

both arbor shaft and bearings. Do not use a blade without a drive pinhole

(Figure 9)

.

•

For safety reasons, EDCO

does not recommend the use of any abrasive blades. Abrasive blades can break and

cause serious personal injury to operator and/or bystanders. If abrasive blades are used by choice, use only rein-

forced abrasive blades. Inspect abrasive blades carefully.

•

Be sure arbor shaft, backing plate and blade cap are clean and in good condition. Flanges should be free of nicks

and burrs. Replace if out-of-round or worn.

Maintenance Instructions

Figure 8

Figure 9