Maintenance instructions, Illustration #2 – EDCO ALR-BS User Manual

Page 10

Printed in USA

©2006

TVW

Page 10

E-ALRE-I-0706

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com • Email: [email protected]

MAINTENANCE INSTRUCTIONS

1. Remove air source and chisel accessory from tool before performing any maintenance.

2. Clean tool daily and keep it clean and lubricated. If a lubricator is provided with the air source, it should be adequate.

If you are unsure or no lubricator is provided, lubricate the tool daily before use by putting 4 to 5 drops of lightweight

machine oil in the hose connector opening. If tool is operated in cold weather (near or below freezing), use a graphite

oil instead of the lightweight machine oil as described above.

3. After every 100 hours of use, fl ush the tool thoroughly with an environmentally safe, nonfl ammable and non-caustic

solvent to clean out any oil/gunk bildup in the tool. Oil tool immediately after fl ushing to prevent corrosion.

4. Replace any damaged parts immediately. Use only genuine EDCO parts.

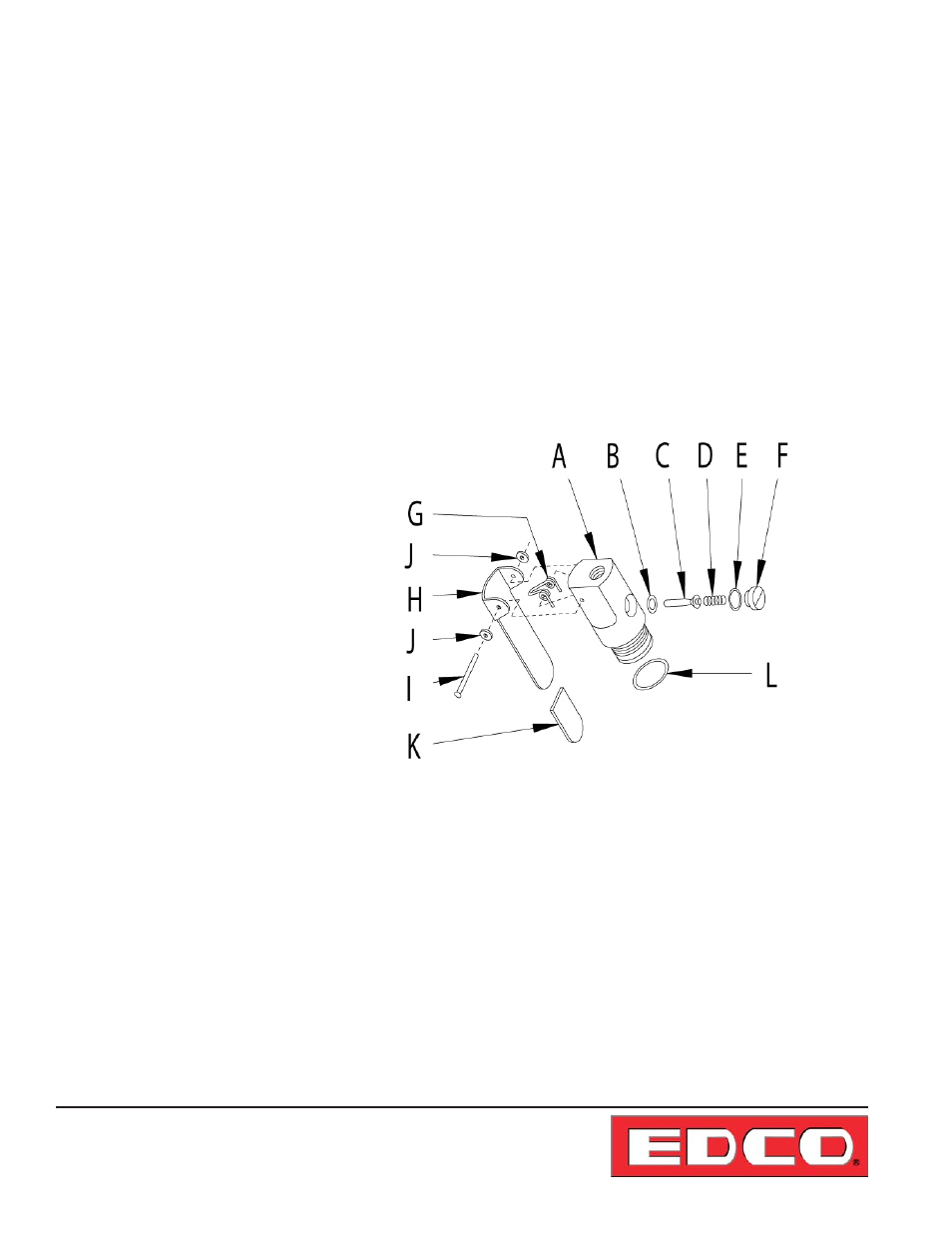

STEPS TO DISASSEMBLE THE AIR

VALVE BODY ASSEMBLY

ILLUSTRATION (#2):

1. To remove Internal Valve Parts:

E - “O” Ring

D - Compression Spring

C - Valve Stem

B - “O” Ring

fi rst remove the Capping screw (F). Note that the Valve Stem (C) should be replaced if it is worn and loose in Valve

Body (A).

2. The “O” Ring (B) for the VALVE Stem (C) may become unseated due to excess air pressure. Check this item if tool

fails to stop running when valve handle is released.

3. The Valve Lever (H) is held in place by the Rivet (I) and two Washers (J).

The “O” Ring (L) must be in place on Valve Assembly (A) to prevent air leaks when assembly is threaded into Cas-

ing (#5) page 9.

NOTE: All “O” Rings should be inspected and replaced if air leakage or damage is detected.

NOTE: Be sure to lubricate all parts with a lightweight machine oil when reassembling the tool.

ILLUSTRATION #2