EDCO CPU-10FC User Manual

Page 11

Printed in USA

TVW

©2005

Page

E-CPU10FC-I-0905

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com • Email: [email protected]

Outrigger Wheel Assembly: (Optional)

Outrigger wheel assembly (Figure 5) is designed to al-

low the drum to follow the contour of the slab. Wheels

are aligned with cutting drum to follow highs and lows

of the slab removing a consistent depth over the entire

surface. Can be used with all accessories but highly

recommended for diamonds and heavy duty roto peen,

removing traffic lines or thin coatings.

Outrigger Wheel

Assembly

(Optional)

Figure 5

Do Not Bottom Cutter Assembly

If front wheels are not in contact with slab surface when

planing you are bottoming the cutter head. You are riding on

the drum & cutter wheels. Cutter wheels will wear uneven

or break if this is continued. (Figure 6)

Re-adjust depth - turn fine adjustment in “up” direction until

cutters are free and cutting is being accomplished by “ham-

mering” action only.

Failure to follow these instructions will cause undue cutter

wear, breakage, bearing failure or excessive vibration that

will be transmitted back to the machine frame and engine

eventually causing a virtual self-destruction of the unit.

Figure 6

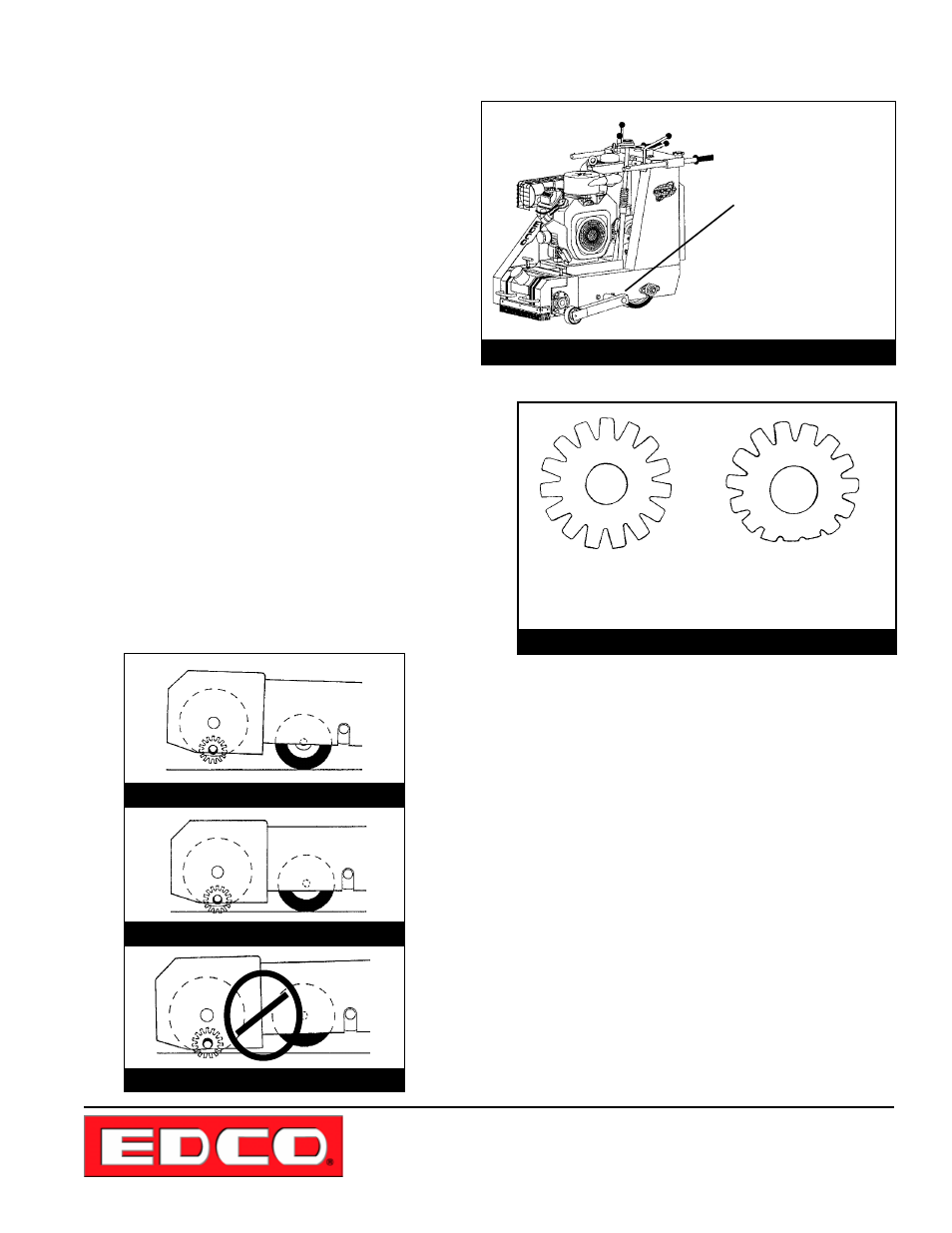

New CP-405

Cutter Wheel

Uneven wear on cutter wheel

caused by cutting too deep or

cutting very hard concrete

“Full Up Position”

Cutter wheels raised from surface for preparation in starting

engine or to stop cutting operation. (Figure 7a)

“Pre-selected Depth”

Depth of cut determined by the hardness of the surface. Cutter

wheels should swing free on shaft.(FIgure 7b)

“Bottomed Out”

This can cause severe damage to equipment or cause cutters

to flatten or break. (Figure 7c)

Cutter wheels are jammed or forced up against shaft by trying

to remove too much in one pass. Wheels are raised from the

surface and front rides on the drum flanges.

Figure 7a

Figure 7b

Figure 7c