Cutter shaft installation, Cutter wheel inspection – EDCO CPU-12 User Manual

Page 9

E-CPU12-I-0113

Printed in USA

TVW

©2013

Page 9

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

Cutter Shaft Installation:

Be sure to disconnect spark plug wires or the

electrical power before changing cutters.

•

Rotate Drum Assembly to expose shaft opening above frame.

•

Insert shaft thru hole and install cutters as required.

•

Rotate drum again to expose the next hole and repeat process.

•

Position lock plate over two shafts and tighten down with

capscrews and lockwashers.

Cutters

Shaft

Capscrews

Un-Locked

Locked

Figure 7

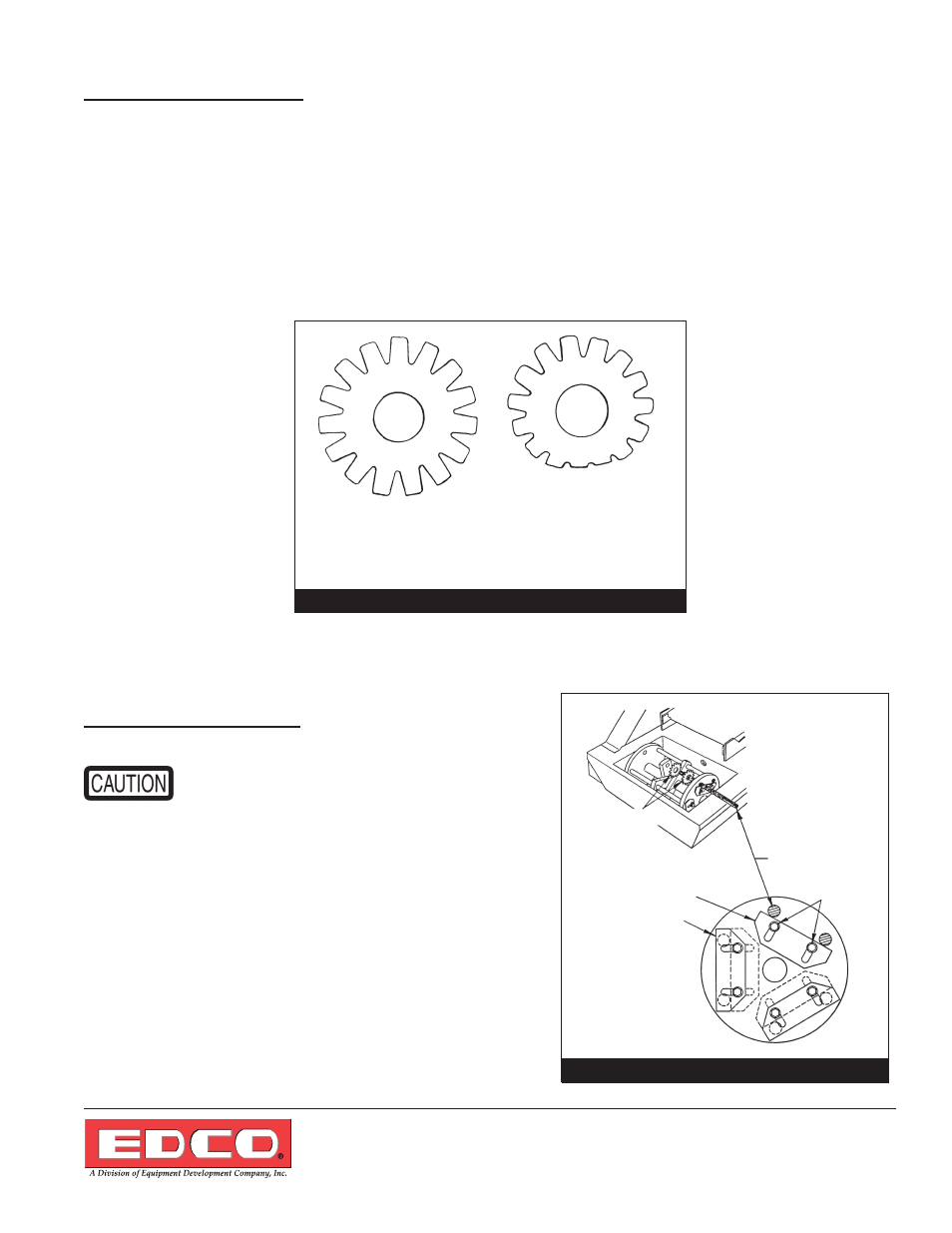

Cutter Wheel Inspection:

•

The steel cutter wheels can be used as long as the teeth can be clearly seen on each cutter wheel and the cutter

wheel edge must be clearly above the drum fl ange edge when pushed towards the drum center. Replace worn

out cutter wheels as a complete set.

•

When changing cutters, check drum assembly for cracks or other damage. Replace bent or worn cutter shafts or

cracked drum assemblies. A maximum of 30% wear on shafts before they must be replaced. Excessive vibration

caused by an out of balance cutter head will cause premature failure of the bearings and fatigue cracks in weld

joints and frames. Do not use damaged or unsafe equipment; repair or replace all damaged parts before pro-

ceeding with operations.

New CP-405

Cutter Wheel

Uneven wear on cutter

wheel caused by cutting

too deep into very hard

concrete

Figure 6