Inspect & tension belts, Blade lift controls – EDCO CPU-12 User Manual

Page 10

E-CPU12-I-0113

Printed in USA

©2013

TVW

Page 10

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

Inspect & Tension Belts:

•

Proper belt tension must be maintained to transmit the engine power to the cutter drum. Slipping belts will over

heat, the cutter life will be shortened and the cutting speed limited. Over tensioned belts will shorten the belt and

bearing life. 70 ft. lbs. of defl ection at the center between the pulley’s, is recommended.

!! IMPORTANT!!

After tensioning belts make sure engine is level and then tighten all mounting hardware and jam nuts.

•

On new machines and after installation of new belts, adjust belt tension after the fi rst four hours, then tension as

necessary.

•

Loosen engine/motor mounting hardware slightly. (Figure 8)

•

Use the two jack-screw belt tensioning bolts to adjust the

engine/motor until the belts are tight. Re-torque the mounting

hardware.

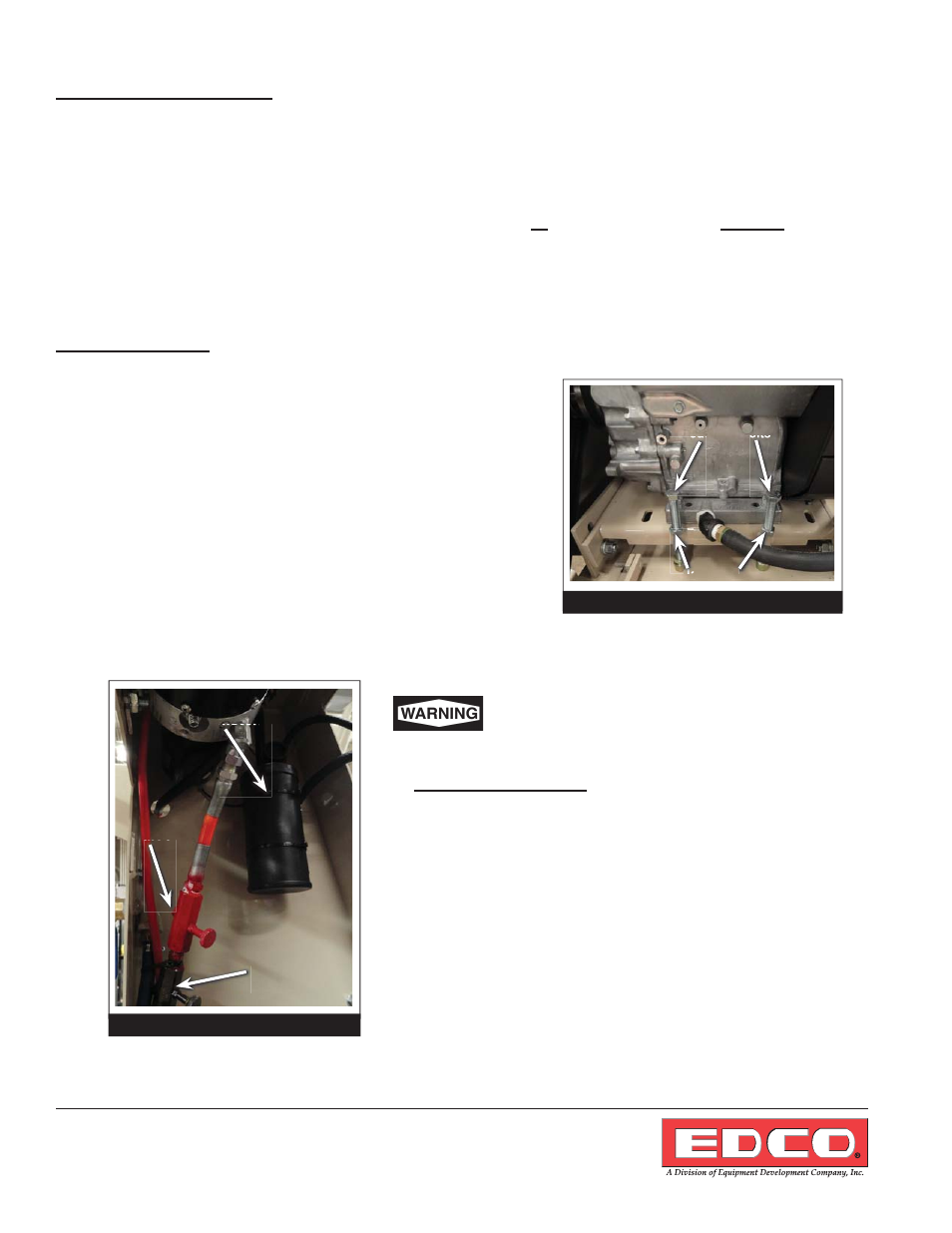

To Tension Belts:

Figure 8

Jacking Bolts

Jam Nuts

Blade Lift Controls:

(Figure 9)

(Controls Hydraulic Fluid Flow)

A - (Red) Blade Lowering Control Valve

To re-adjust:

• Turn

Knob

out-fast

in-slow

•

Retighten lock nut

B- (Black) Blade Raising Control Valve

C- Carbon Canister

Remember to remove all rings, watches

and jewelry prior to doing maintenance near

hydraulic pump!

Figure 9

A - Blade

Lowering

Control

Valve

B - Blade

Raising Con-

trol Valve

C - Carbon

Canister