Maintenance – EDCO TG-10 User Manual

Page 9

E-TG10-I-0612.3

Printed in USA

TVW

©2012

Page 9

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

Maintenance

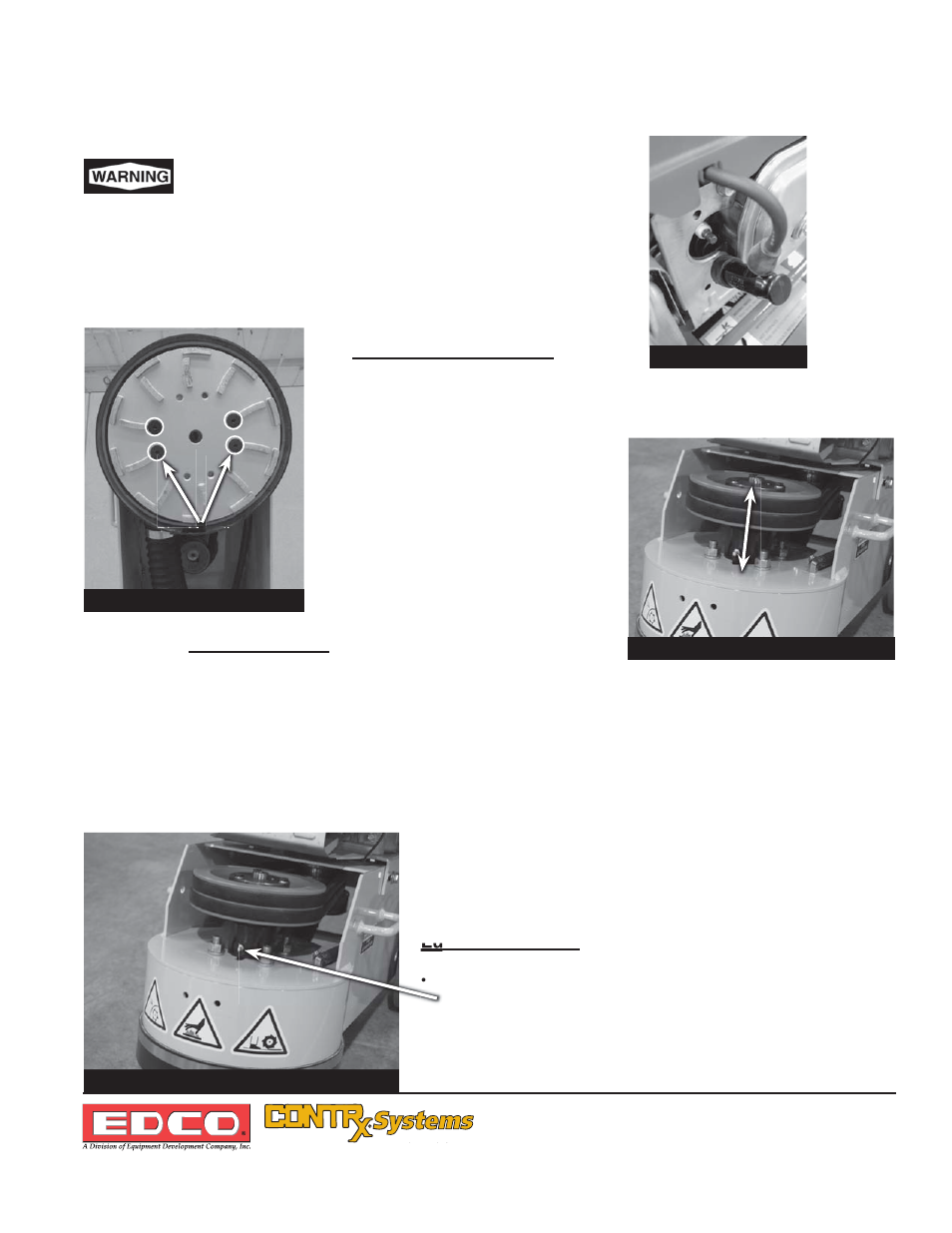

Disconnect spark plug lead (Figure 10) before per-

forming any maintenance on this machine! Or on the

electric model, unplug the electric cord at the machine

(instead of at the wall) to assure the machine will

remain un-plugged while you are working on it.

Inspect Every 8 Hours:

•

Inspect the disc mounting screws. (Figure 11) The constant vibration

and heat generated, especially when grinding dry, could cause the

screws to loosen and the disc to become off balance.

Follow the engine manufacturer’s guidelines for regular maintenance.

Lubricate Weekly:

• Bearings (Figure 12) must be lubricated weekly with

Lubriplate 930-AA High Temp Grease or equivalent.

• Belt guard has to be removed to access bearing lubrication

fi tting.

Figure 10

Figure 12

Figure 11

Disc Mounting

Screws

After every use:

•

Inspect for lash in head (Does head move up/down) ? (Figure 11A).

Verify that jam nuts, items 10 on page 9 in Parts Breakdown are tight and there isn’t any play.

Allowing these nuts to remain loose can damage the head assembly.

•

If movement is noticed, STOP. Damage to head assembly may occur. In order to tighten these

nuts the sheave under the hood must be removed. Bottom nut should be tightened and then

backed off until head turns freely. Then top nut should be tightened down and jammed using two

wrenches turning in opposite directions. After tightening make sure head still turns freely.

Figure 11A