Discs – EDCO TG-10 User Manual

Page 8

E-TG10-I-0612.3

Printed in USA

©2012

TVW

Page 8

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

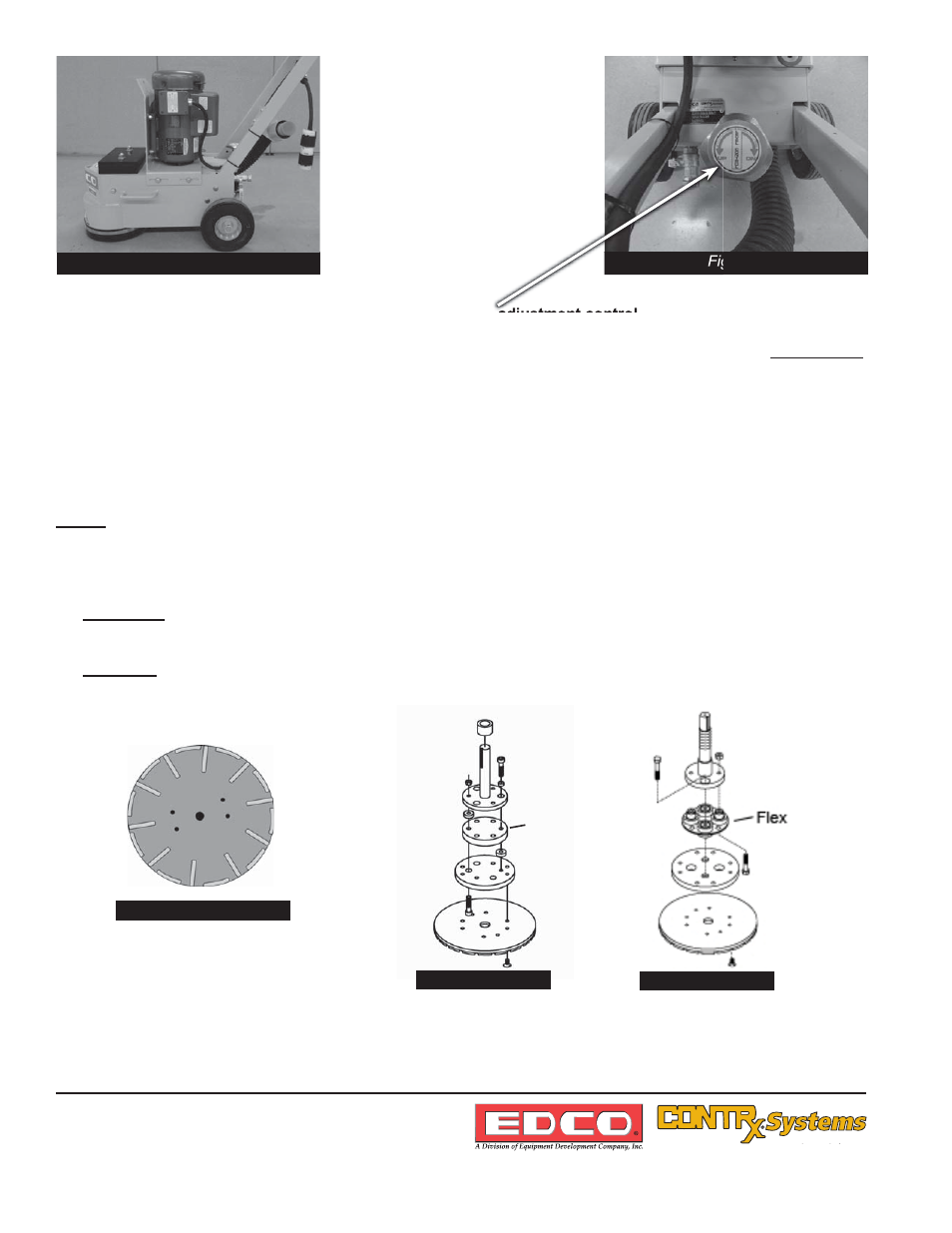

Discs:

•

Inspect the disc (Figure 8) periodically to determine it’s wear characteristics, if signs of uneven wear appear the

cause should be determined and corrected. If repairs are needed contact EDCO or your EDCO representative.

• Rigid Head can be used on uneven expansion joints, high spots, joint curls and bridge decks, removing coatings

and grinding rough concrete surfaces. Use with a vacuum or water for dust control but not the same time.

• Flex Head can be used preparing a smooth, fl at fl oor to receive a new coating, removing coatings, grind rough

concrete surfaces. Can be used with a vacuum or water for dust control but not the same time.

•

Each new machine is shipped with a RIGID HEAD (FLEX HEAD OPTIONAL) 10”/255 mm factory balanced disk.

It is important to maintain the coupling to which the disk is attached. A worn coupling, damaged bearings or a bent

shaft will cause the grinding discs to wear unevenly. (Figure 9 rigid head assembly & 9A fl ex head assembly.) It is

important to note FLEX HEAD for smooth fl at surfaces, RIGID HEAD for buckled, bumpy or rough surfaces.

Figure 8

Disc shown is for reference

only.

Standard RIGID HEAD

Rigid

Figure 9

Figure 9A

Optional FLEX HEAD

Figure 6

Comments in paragraph below are in reference to this level adjustment control.

NOTE: Ensure when leveling the machine as explained below that it (the machine) is sitting on a

FLAT LEVEL

surface otherwise adjustments may not be correct for the surface being worked on.

If rear of grinding disc is higher (not touching the work surface) than the front of the disc (touching the work

surface) turn this control (Figure 7) counter clockwise until disc sits level (fl at) on the work surface.

If front of grinding disc is higher (not touching the work surface) than the rear of the disc (touching the work

surface) turn this control (Figure 7) clockwise until disc sits level (fl at) on the work surface.

Figure 7