Build the fuselage assemble the firewall, Glow engine installation – Dynaflite GPMA0510 Super Decathlon User Manual

Page 15

15

❏ ❏ 5. Shape the leading edge, hinge doublers and

the control horn support to the shape of the ribs.

❏ ❏ 6. Sand the trailing edge of the sheeting to the

same angle as the top of the ribs.

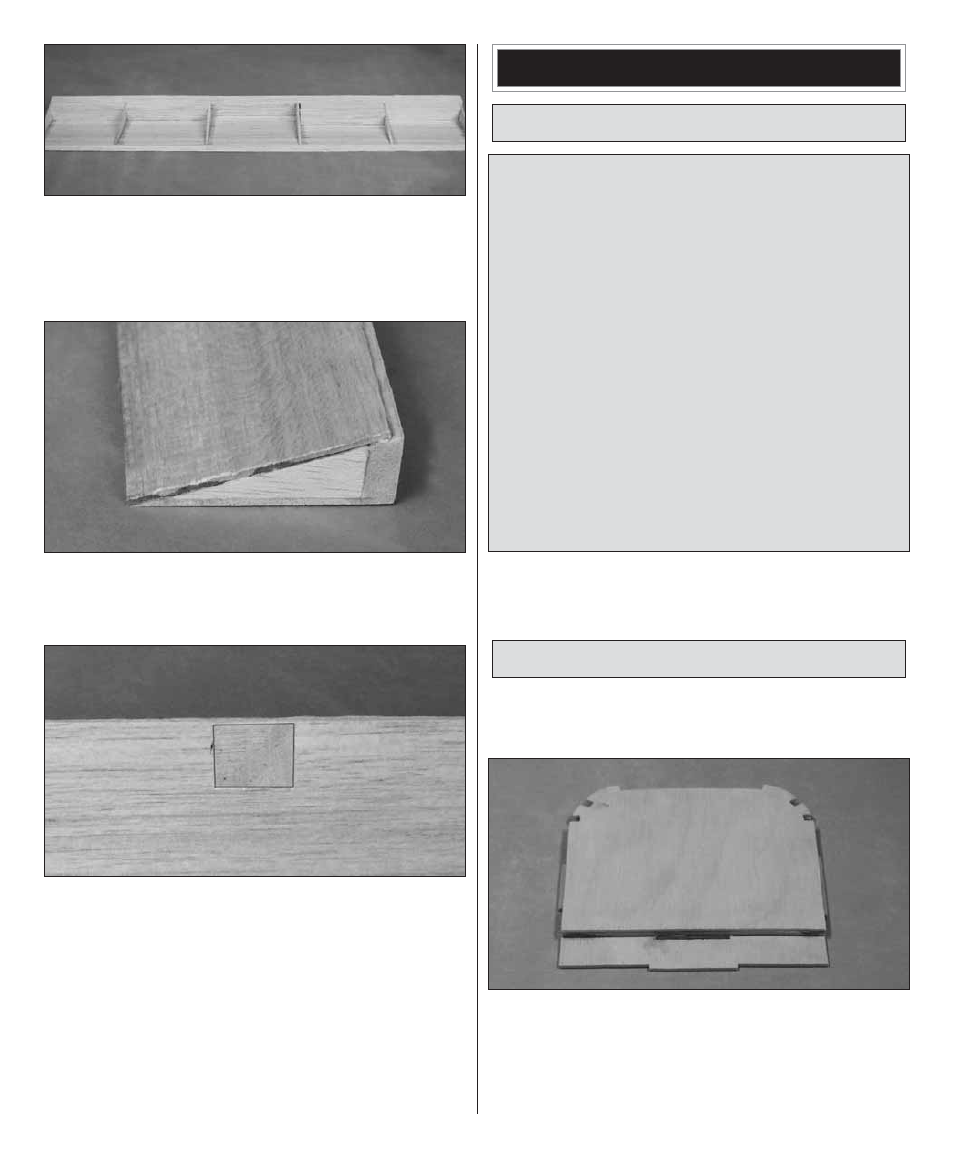

❏ ❏ 7. Glue the other 3/32" x 3" x 18-9/16" balsa

aileron sheet in place. Note: Align the trailing edge

of the sheeting as shown in the photo.

❏ ❏ 8. Position and trace around the die-cut 1/8"

ply control horn mount on the bottom of the aileron.

Remove the control horn mount. Cut and remove

the 3/32" sheeting from the area you traced. Glue

the control horn mount in place and sand it flush

with the aileron sheeting.

❏ ❏ 9. Sand the leading edge to a V-shape, using

the cross section at W5 on the plans as a guide.

❏ 10. Repeat steps 1-9 for the other aileron.

BUILD THE FUSELAGE

ASSEMBLE THE FIREWALL

We tested our prototype Super Decathlons with an

O.S.

®

1.20 4-stroke and with a 25cc US Engine

™

.

From this point forward when we refer to a glow

installation, we are referring specifically to the

steps we took to install the O.S. 1.20 4-stroke.

Similarly, when we refer to gas installation, we are

referring specifically to the steps we took to install

the US 25. If you are installing a gas or glow

engine other than those listed above, you may

need to modify these steps somewhat to

accommodate your particular engine.

Note: The pieces used to assemble the engine

mount for the gasoline engines are also utilized as

engine mount spacers to position the glow engine

sufficiently forward from the firewall. For clarity, we

will refer to this assembly as “engine mount spacer”

in the glow sections; however, please note that it is

the same piece as the gasoline engine mount.

GLOW ENGINE INSTALLATION

The following 13 steps are for glow installation.

Skip these steps if you are using a gas engine.

❏ 1. Select the three die-cut 1/8" ply firewall pieces

A, B and C. With the embossed labels toward the

desk top, laminate B onto A then C onto B, all with

6-minute epoxy. This assembly is now known as

the firewall.

15