Viii. checking and trouble shooting, 14 checking reference – COMEUP Compact Winch (Ver:00) User Manual

Page 16

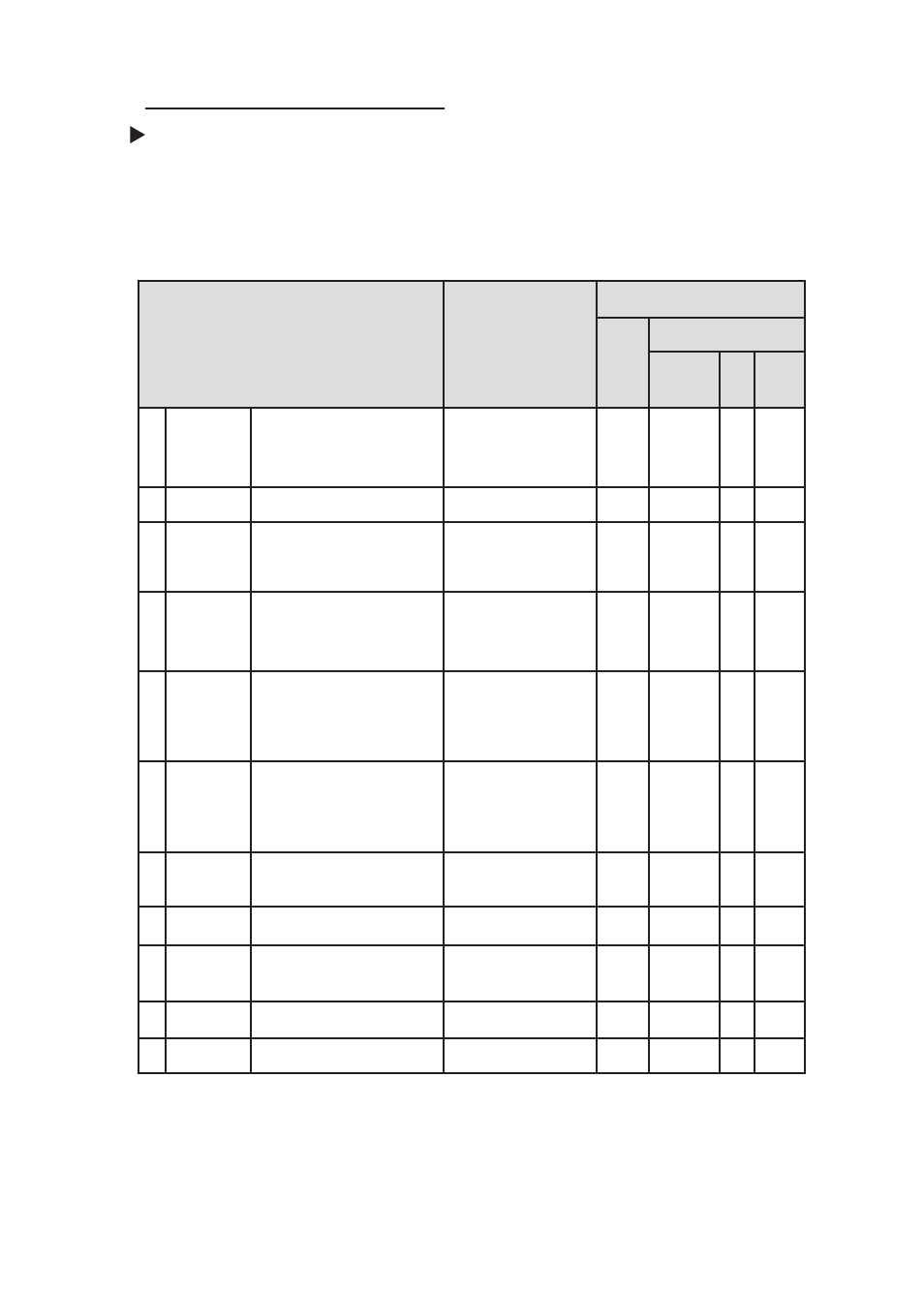

VIII. Checking and Trouble Shooting

14

Checking Reference

Remark1. The specified person performs the checking of winch.

2. Divide the checking into daily checking and periodic checking.

3. The checking items and checking method in daily and periodic checking shall

be carried out and different according to the using frequency.

Checking items

Checking Methods

Classification of Checks

Daily

periodical

3 Months/

20 Hours

1

year

3 Years

or 250

Hours

1 Brake

Performance

Brake or escaping of spring

Visual

Decomposition check

Decomposition check

2 Carbon brush Wearing

Decomposition check

3 Motor

Condition of insulation

Staining , damage

Carbon powder accumulation

Measuring,50M

Ω

min

Visual

Decomposition check

4 Remote

control

Working

Outer damage of switch cords

Attaching condition of earth line

Condition of insulation

Manual

Visual

Visual

Measuring,50M

Ω

min

5 Safety device

Over-prevention function

Reverse winding prevention function

Distortion of over winding lever

Visual

Visual

Visual

Visual

6 Wire rope

Kink phenomena

Broken wires

Decreasing of diameter more than 10%

Deforming or corrosion

Visual

Visual

Visual

Visual

7 Weight hook

and hanger

Distortion

Damage

Loosening

Visual

Visual

Visual

8 Drum

Rupture of flange

Wearing

Visual

Visual

9 Gear trains

Damage , warning

Condition of oil feeding

Lubrication for couplings

Visual

Measuring

Measuring

10 Fastenings Loosening

Manual

11 Marking

Label and the like

Manual

Wearing of lining, and pressed plate

Wrong rotary direction-winding