Crown Boiler MWC116ENL User Manual

Page 59

57

Remove the monometer and make sure that the inlet and manifold pressure tap screws are closed

9)

Check the entire gas train for leaks. Fix any leaks found immediately.

10)

Run the gas valve safety shut-down test. With the boiler fi ring, close the gas cock upstream of the boiler.

11)

The gas valve should close as soon as loss of fl ame is detected (within a few seconds of closing the gas

cock). The boiler should then make one attempt to relight before going into a hard lockout. To reset the

boiler, push the red reset button, rotate the heating system knob back to zero for a few seconds, then

rotate the heating system knob fully clockwise.

Run a combustion test with the boiler operating at high fi re. CO2 or O2 readings should be reasonably

12)

close to the values shown in Table 12.8. The CO level should be less than 50PPM. Consult the factory if

the CO level is exceeded or if the CO2 or O2 are signifi cantly different from the valves shown.

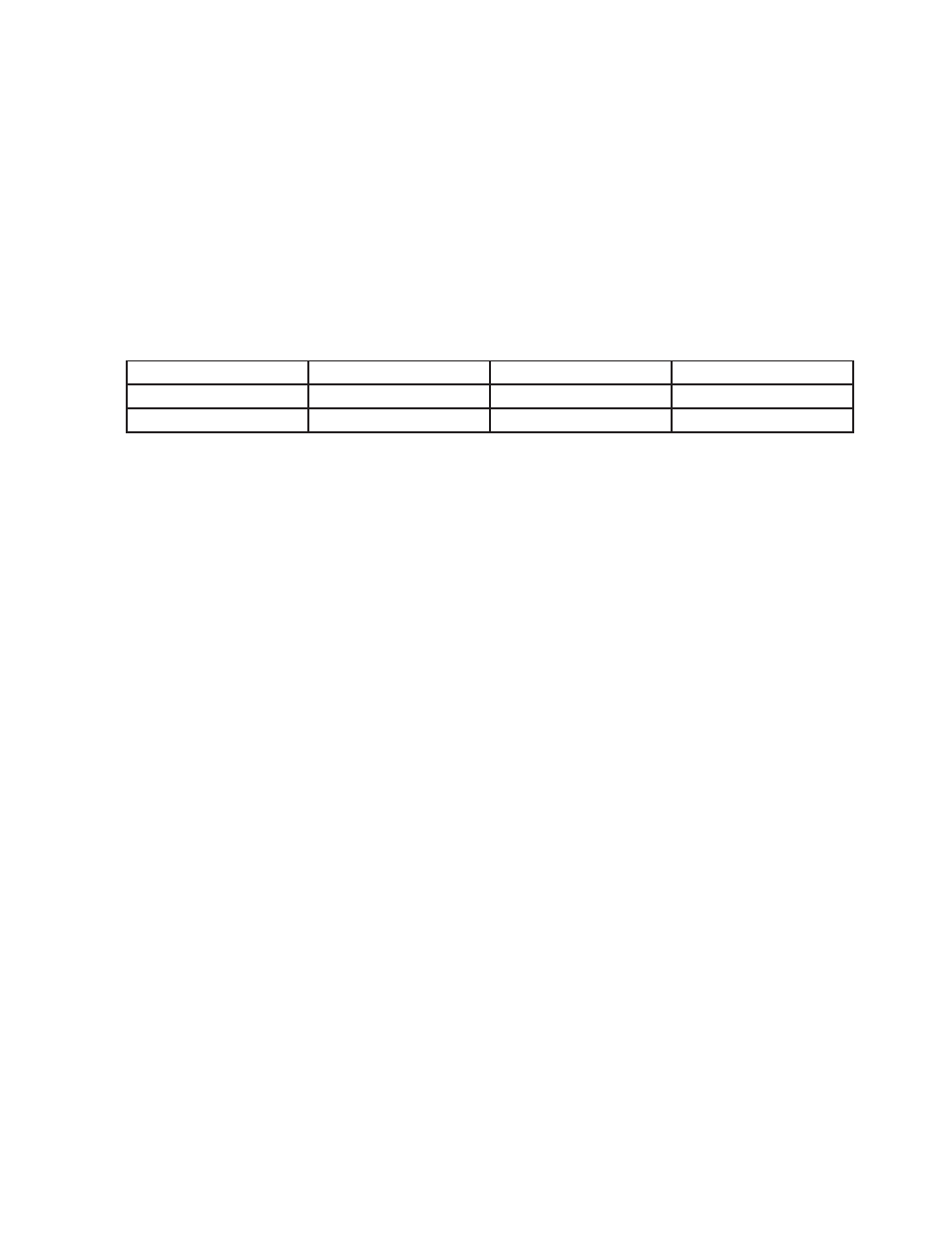

Table 12.8: High Fire Combustion Readings

Fuel

Approx. O

2

(%)

Approx. CO

2

(%)

Maximum CO (PPM)

Natural Gas

9.7

6.3

50

Propane

9.5

7.5

50

Verify that the fl ue system is tight and securely assembled in accordance with the Venting section in this

13)

manual.

Replace all jacket panels

14)

After the boiler has operated for at least 30 minutes recheck the boiler and system for leaks. Repair ant

15)

leaks found before leaving the boiler in operation.

Test any external limits or other controls in accordance with the manufacturer’s instructions.

16)

Verify that the boiler starts and stops in response to calls for heat from the heating thermostat/s. Make

17)

sure that the appropriate circulators also start and stop in response to the thermostats.

Set the Heating System Knob and the DHW knob for the desired target supply and DHW temperatures

18)

(see the Operation section for more information on how to do this).