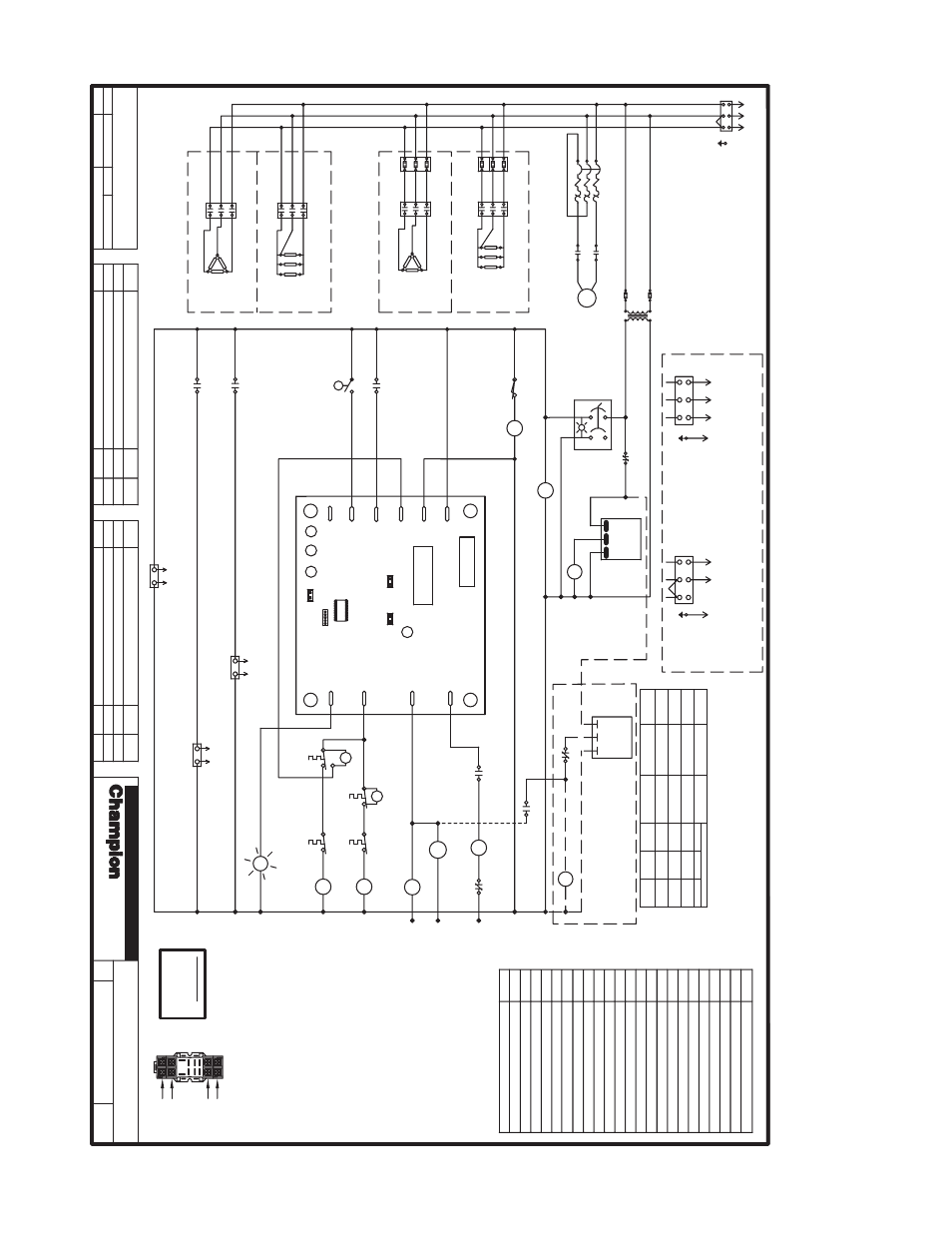

Electrical schematic – Champion Manufacturing DH2000 User Manual

Page 44

36

Electrical Schematic

BY

DA

TE

DESCRIPTION

RE

V.

B

RE

V.

The Dish

washing Machine Specialists

RE

V.

DESCRIPTION

DA

TE

BY

CUST

OMER

TO

SUPPL

Y RA

TED

VOL

TA

GE/PHASE/H

z,

AS SPECIFIED PER ORDER,

TO

DISC

ONNEC

T SWIT

CH.

ALL POWER SUPPLIED

TO

EA

CH C

ONNE

CT

ION POINT

MUST

CO

MP

LY

WITH ALL

LO

CAL ELEC

TRIC

CO

DES.

SCAL

E

DR.B

Y

DA

TE

SHEE

T

OF

1 & 3 PHASE DH/MD2000 DOOR MA

CHINE

702119

B

NONE

J. MCALLISTER

30MAR0

9

1

1

NO

NC

CO

IL

CO

MMON

RELA

Y

**

N

NEUTRA

L

B

REVISED DRAIN

TEP

MERING CIRCUI

T

18A

UG09

JA

M

ELEC

TRIC BOOSTER HEA

T

L3

L2

L1

L3

L1

37

38

37

BC

36

BC

36

34

L2

L1

L3

31

32

FU

30

SEE NO

TE 1

35

34

HC

33

5.2K

W

ELE

CT

RIC

TA

NK HE

AT

L1

L2

30

FU

31

33

HC

5.2K

W

L1

L3

L2

1.) SE

T ME

TER

TO

READ DC

VOL

TA

GE

HL

TS

HL

TS

VENT

FA

N

CO

NT

AC

TO

R

120V SIGNAL

TO

4

1M

21

FSW

1CRA

2CRA

9

8

20

17

19

TS

B

TS

W

14

15

A CL

OSED SWIT

CH

WILL READ 0-1VDC

4.) AN OPEN SWIT

CH

WILL READ 4.7-5.3VDC

i.e

. PLA

CE RED LEAD

TO

T8

TO

T

EST DOOR SW

.

3.) PLA

CE RED LEAD

TO

TERMINAL BEING

TESTED

END OF CY

CLE

DI

AG

RAM ST

AT

E

POWER OFF

TANKS EMPT

Y

DOORS CL

OSED

2

2.) PLA

CE BLA

CK LEAD

TO

T2

18

2

LT

1

BC

HC

16

RW

V

1M

DSS

6

1CR

2

7

4

13

10

1CRB

11

4

LO

AD

3CR

3CR

PCB

LINE

3

TO

TEST INPUTS

T7,

T8, AND

T9 A ME

TER

CAP

ABLE OF READING DC

VO

LT

AG

ES MUST

BE USED

.

TANK HE

AT

CONT

AC

TO

R

RINSE

TIME SELEC

T JUMPER

POWER CIRCUIT BREAKER

BOOSTER

TANK

THERMOST

AT

PCB

RWV

TS

B

TS

W

2CR

1MOL

12

RINSE

WA

TER

VA

LV

E

W

ASH

TANK

THERMOS

TA

T

HL

TS

FSW

FU

HC

JB2

JB3

5

DV

2

LT

1

JB1

DT

10 MINUTE

12

3

1

2

F1

CY

CLE SELE

CT

JUMPER

CY

CLE SELE

CT

JUMPER

CY

CLE LIGHT

HIGH LIMIT

THERMOST

AT

TIMER BO

ARD FUSE

FL

OA

T SWIT

CH

FUSE

BOOSTER

TA

NK

CO

NT

AC

TO

R

DOOR SAFE

TY

SWIT

CH

3CR

2CR

1CR

BC

DSS

DT

V

AS

GND

1M

ARC SUPPRESSOR

DRAIN

TEMPERING

VA

LV

E

DRAIN

VA

LV

E RELA

Y

RINSE AID RELA

Y

DOOR SWIT

CH RELA

Y

W

ASH MO

TOR C

ONT

AC

TO

R

L1

L2

L3

RINSE AID SIGNAL

DE

TERGENT SIGNAL

G

HE

AT

ERS

OUTPUT

EX

T.

WA

SH

(C

YC

LE SW

.)

FL

OA

T SW

.

LAMP

OUTPUT

DOOR SW

.

ST

ART SW

.

(RINSE SENT

RY

)

N

H

WA

SH

OUTPUT

RINSE

OUTPUT

H

POWER

L3

32

L2

35

38

L1

L2

SEE NO

TE 1

FOR

THREE PHASE OPER

AT

ION REMOVE JUMPER BEE

TW

EEN L2 AND L3.

FOR SINGLE PHASE OPERA

TION LEA

VE

THE JUMPER INS

TA

LLED AND

CO

NNE

CT

HE

AT

ERS AS SHOWN BEL

OW

.

AS

7

7

4

13

GND

1 AMP MA

X

1 AMP MA

X

1

2

2

2

2

2

2

DT

DRAIN

TIMER

N

SINGLE PHASE

THREE PHASE

THREE PHASE

SINGLE PHASE

7

20

21

2

2

4

2

7.5K

W

7.5K

W

208-240V 1 OR 3 PHASE

GND

L2

L1

SINGLE PHASE

THREE PHASE

1 PHASE-

CIRCUIT CA

PA

CI

TY

80AMPS

1 PHASE-MA

X BREAKER 80AMPS

3 PHASE-MA

X BREAKER 50AMPS

3 PHASE-

CIRCUIT CA

PA

CI

TY

50AMPS

19

8

9

FU

LINE

120V

FU

T1

4

4

4

2

2

13

2

1MTR

27

28

1M

50

24

25

1MOL

L1

50 L2

2

2

IF CHANGE AND/OR REVISE MAKE SURE

TO

UP

DA

TE

PA

RT# 114656, SCHEMA

TIC PEEL

-OFF

LABEL

14

4

L2

L1

AS

3

2

1

30 SEC

T2

DT

V

2

3

51

51

52

3CRB

13

51

3CRB

T2

DRAIN

TEMPERING

TIMER

DV

DRAIN

VA

LV

E

IF USED

DRAIN

TEMPERING KIT

! AT

TENTION -

VER

Y IMPORT

ANT ! -

VERIFY

CIRCUIT BO

ARD

PA

RT NUMBER AND JUMPER POSITION

SE

TTINGS (

JB1, JB2, JB3) PER MA

CHINE MODEL AND

SERIAL NUMBER AS INDICA

TED IN

TABLE BE

LO

W.

IMPROPER JUMPER SE

TTINGS MA

Y CA

USE ERRA

TIC

OPERA

TION.

MA

CHINE BO

ARD JUMPER SE

TTINGS

MODEL SERIAL NUMBER

PA

RT NUMBER JB1 JB2 JB3

LEDs

WA

SH

T10

RINSE

FILL

T9

JB2

T6

T5

FUSE 1A

T7

T8

T2

T1

F1

JB1

JB3

POWER

LED

T4

T3

5 X 20 MM

FA

ST

AC

TING

DH/MD2000 D09037592 114470 OPEN OPEN OPEN