Service and adjustment, Tank (sediment) cleaning, Venting system inspection – Kenmore POWER MISER 153.336951 User Manual

Page 16: Awarning, Burner inspection, Burner cleaning, Tank (sediment) cleaning venting system inspection, Burner inspection burner cleaning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Service and Adjustment

Tank (Sediment) Cleaning

Sediment build-up on the tank bottom may create varying

amounts of noise, and if left in the tank will cause premature

tank failure. In some water areas, you may not be able to drain

all sediment deposits by simply draining the tank. In these cases

Mag Erad (part no. 23600) can be used to help remove the sedi

ment deposits. This may be ordered from the Sears Service

Center. For ordering, refer to the “Parts Order List” section.

Venting System Inspection

At least once a year a visual inspection should be made of the

venting system. You should look for:

• Obstructions which could cause improper venting. The com

bustion and ventilation air flow must not be obstructed.

• Damage or deterioration which could cause improper venting

or leakage of combustion products.

• Rusted flakes around top of water heater.

AWARNING

Chemical vapor corrosion of the flue and vent system may

occur if air for combustion contains certain chemical vapors.

Spray can propellants, cleaning solvents, refrigerator and air

conditioner refrigerants, swimming pool chemicals, calcium

and sodium chloride, waxes, bleach, and process chemicals are

typical compounds which are potentially corrosive.

AWARNING

Obstructed or deteriorated vent systems may present a serious

health risk or asphyxiation.

AWARNING

Be sure the vent piping is properly connected to prevent

escape of dangerous flue gasses which could cause deadly

asph^iation.

_______________ AWARNING_________________

If after inspection of the vent system you found sooting or

deterioration, something is wrong. Call the local gas utility to

correct the problem and dean or replace the flue and venting

before resuming operation of tiie water heater.

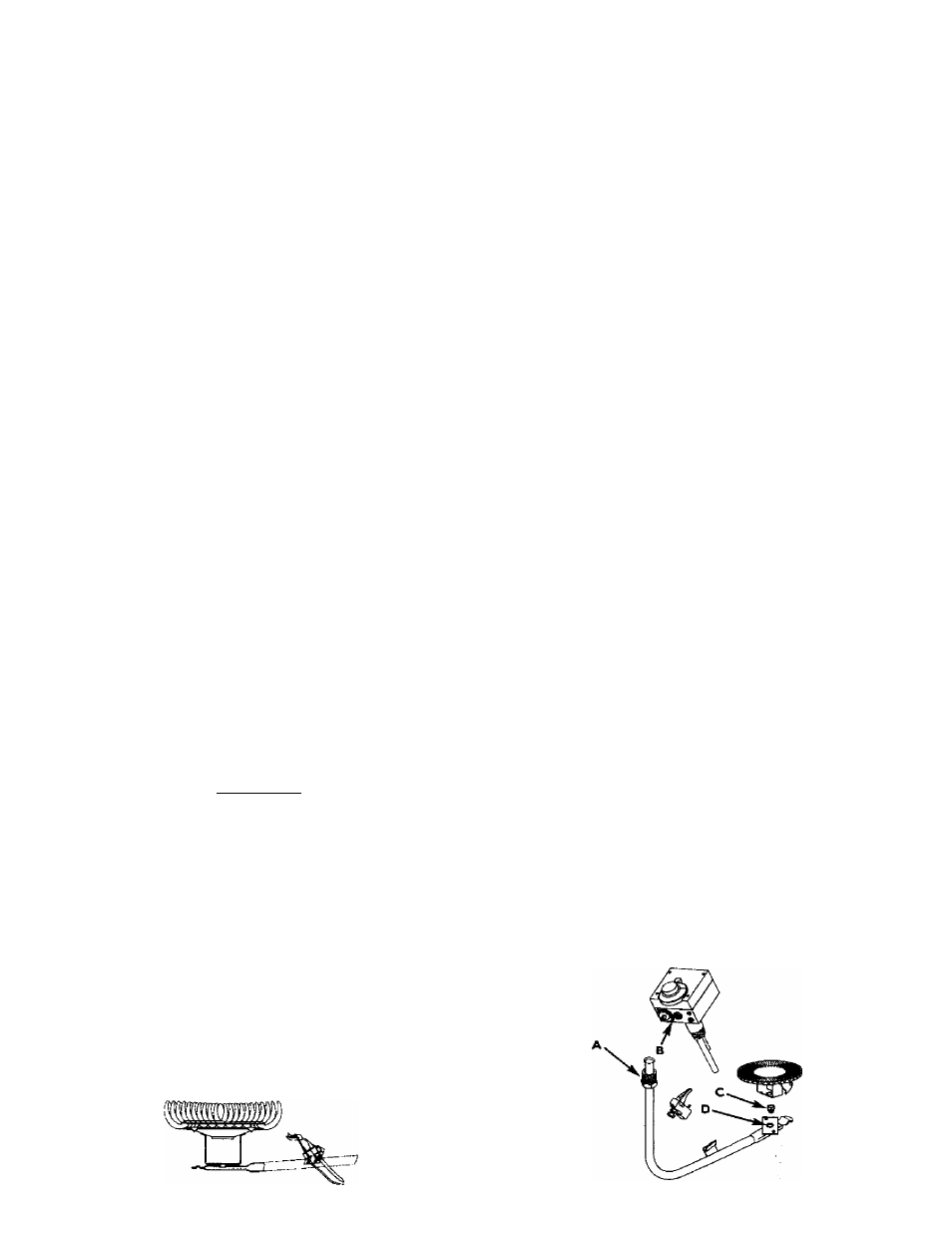

Burner Inspection

AWARNING

Do not use this affiance if any part of it has been under vrater.

Immediately call a Sears Service Technician to inspect the

appliance and to replace the gas control or any part of the

burner system which has been under water.

At least once a year a visual inspection should be made of the

main burner and pilot burner. The drawing is for your reference.

You should check for sooting which is not normal and will

impair proper combustion.

AWARNING

Soot build-up indicates a problem that requires correction

before further use. Turn “OFP’ gas to water heater and leave

"OFF” until repairs are made, because failure to correct the

cause of the sooting can result in a fire or explosion causing

DEATH, SERIOUS BODILY INJUW; OR PROPERTY DAMAGE.

Burner Cleaning

inspection of the burner shows chat cleaning is required, turn

e gas control knob clockwise (to the “OFF” position.

In the event your burner needs cleaning, use the following

instructions:

If

_

the gas

depressing slightly.

NOTE: The knob cannot be turned from “PILOT” to “OFF’

unless knob is depressed slightly. DO NOT FORCE.

Loose deposits on or around the burner can be removed by care

fully using the hose of a vacuurn cleaner inserted through the

access door of the water heater. If the burner needs to be removed

for additional cleaning, call the Sears Service Center to remove

and clean the burner and correct the problem that required the

burner to be cleaned.

LR Gas Control Valve & Burner

Assembly Replacement

Information

AWARNING

PROPANE (LP.) GAS CONTROL VALVE AND BURNER

ASSEMBLY REPLACEMENT INFORMATION.

For Propane (L.P.) Gas Models Only:

Your water heater is equipped with a Propane (LR) gas

control valve and a main burner assembly with left hand

threads for the following fittings and their connections.

(1)

The

connection

between

the

manifold

and

the

gas control valve (A to B) are left hand threads.

(2)

The

connection

between

the

main

burner

ori

fice

and

the

manifold

(C

to

D)

are

left

hand

threads.

For

ordering

these

replacement

parts,

please refer to the “Parts Order List" section of

this manual.

20