Water piping, Installation instructions (cont’d) – Kenmore 153.337002 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Combustion Air and

Ventilation for Appliances

Located in Confined Spaces (contM)

Installation Instructions (cont’d)

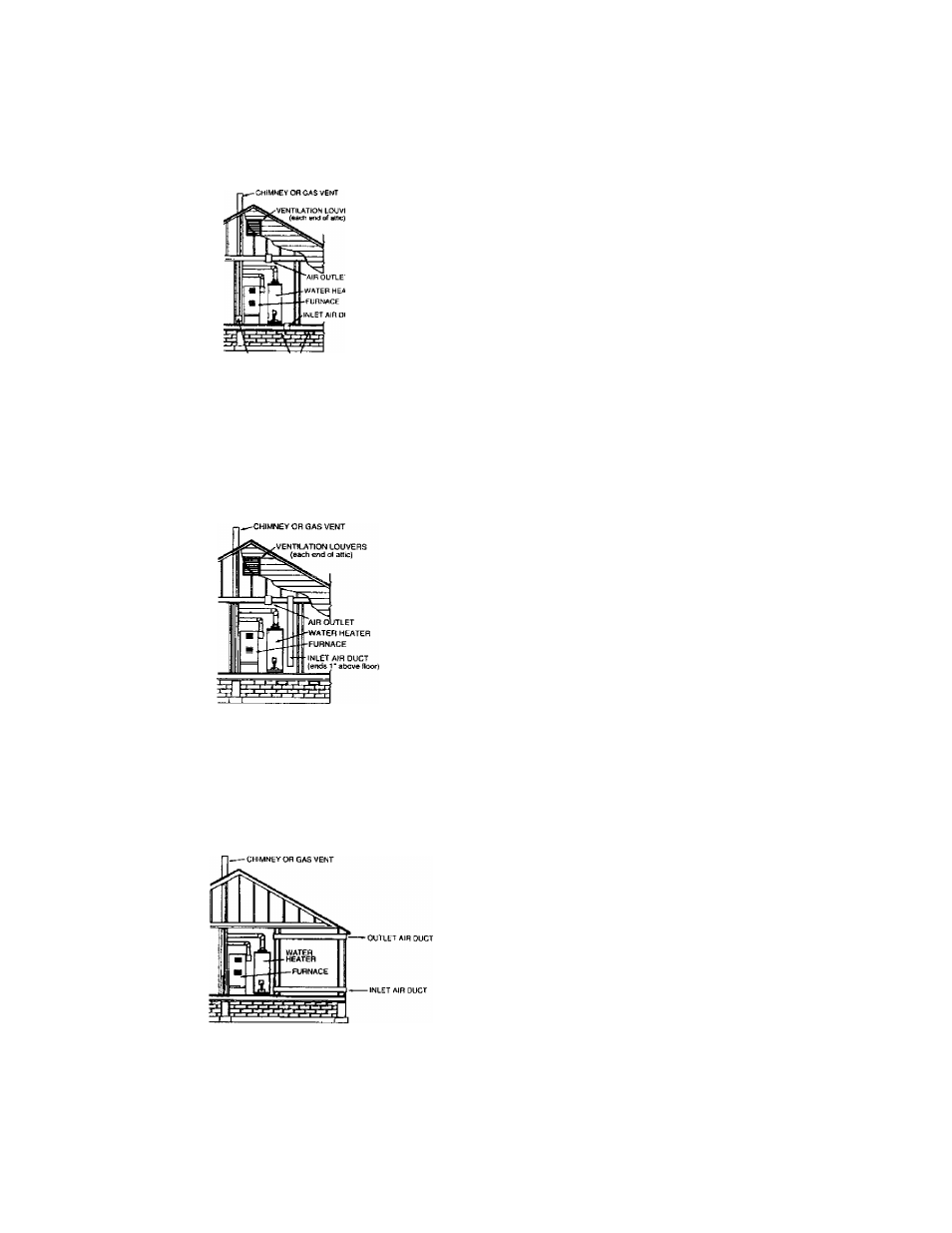

Figure 7

ALT INLET Alp VÉIMTILATION LOUVERS

1. When directly communicating with the outdoors, each open

ing shall have a minimum free area of 1 square inch per 4,000

BTU per hour of total input rating of all equipment in the

enclosure. (See Figure 7.)

2. When communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of 1

square inch per 4,000 gTU per hour of total input rating of

all equipment in the enclosure. (See Figure 8.)

Figure 8

3. When communicating with the outdoors through horizontal

ducts, each opening shall have a minimum free area of 1

square inch per 2,000 BTU per hour of total input rating of

all equipment in the enclosure. (See Figure 9.)

Figure 9

4. When ducts are used, they shall be of the same cross-sectional

area as the free area of tne openings to which they connect.

The minimum short side dimension of rectangular air ducts

shall not be less than 3 inches. (See Figure 9.)

5. Louvers and Grilles: In calculating free area, consideration

shall be given to the blocking effect of louvers, grilles or

screens protecting openings. Screens used shall not be smaller

than

'A

inch mesh. If the free area through a design of louver

or grille is known, it should be used in calculating the size

opening required to provide the free area specified. If the

design and free area is not known, it may be assumed that

wood louvers will be 20-25 percent free area and metal louvers

and grilles will have 60-75 percent free area. Louvers and

grilles shall be fixed in the open position or interlocked with

the equipment so that they are opened automatically during

equipment operation.

6, Special Conditions Created by Mechanical Exhausting or

Fireplaces: Operation of exhaust fans, ventilation systems,

clothes dryers or fireplaces may create conditions requiring

special attention to avoid unsatisfactory operation of installed

gas utilization equipment.

Water Piping

A WARNING

HOTTER WATER CAN SCALD; Water heaters are intended to

produce hot water. Water heated to a temperature which will

satisfy xiothes washing, dish washing, and other sanitizing needs

can »raid and permanently injure you upon contact. Some peo

ple are more litely to be permanently injured by hot water than

others. These include the elderly, children, the Infirm, or physical-

iy/mentally handicapped. If anyone using hot water in your home

fits into one of these groups or K there is a local code or state law

requiring a certain temperature water at the hot water tap, then

you must take special precautions. In addition to using the lowest

possible temperature setting that satisfies your hot water needs,

a means such as a mixing valve, should be used at the hot water

taps used by these people or at the water heater. Mixing valves

are

available at plumbing supply or hardware stores. Follow man

ufacturers instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

“Temperature Regulation’’ section in this manual.

This water heater shall not be connected to any heating systems

or component(s) used with a non-potable water heating

appliance.

If a water heater is installed in a closed water supply system; such as

one having a back-flow preventer, check valve, water meter with a

check valve, etc... in the cold water supply; means shall be provided

to control thermal expansion. Contact the local utility or local Sears

Service Center on how to control this situation.

NOTE: To protect against untimely corrosion of hot and

cold water fittings, it is strongly recommended that di-elec

tric unions or couplings be installed on this water heater

when connected to copper pipe.

NOTE: If using copper tubing, solder tubing to an adapter

before attaching the adaptor to the cold water inlet connection.

Do not solder the cold water supply line directly to the cold

water inlet. It will harm the dip tube and damage the tank.

12