Normal operating sounds, Maintenance schedule, Operating instructions – Kenmore 70089 User Manual

Page 23: Care and maintenance a warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Operating Instructions

Normal Operating Sounds

Certain sounds may be made when air conditioner runs,

especially in a cooling mode. Sounds may include:

• Water splashing onto condenser; caused by slinger

ring attached to condenser fan. Slinger ring picks up

water (condensate) in base pan and sprays it on

condenser to increase efficiency of unit.

Compressor cycles frequently. High efficiency

compressors used in new Kenmore Room

AirConditioners run more frequently but for shorter

periods and consume less energy than older, less

efficient compressors.

Airflow from air discharge vent. If sound is distracting,

try adjusting louvers on discharge vent, moving objects

that may be obstructing airflow, or reducing fan speed.

Care and Maintenance

A WARNING

To avoid death or personal injury due to electrical

shock, turn off fan control and unplug power cord

before cleaning or performing maintenance on this

device.

Maintenance Schedule

Kenmore Room Air Conditioners are designed and

manufactured to provide years of dependable service

when properly cared for and maintained.

Maintenance Schedule (below) shows maintenance

required to keep unit operating at peak efficiency. Most

maintenance can be performed using common tools,

equipment, and products. See Maintenance Procedures

(beginning on page 24).

Large maintenance tasks, such as washing condenser

and evaporator coils, should performed by an authorized

Sears servicer (at owner’s expense). Call 1 -800-4-88

1222 for location of a local authorized Sears Service

Center.

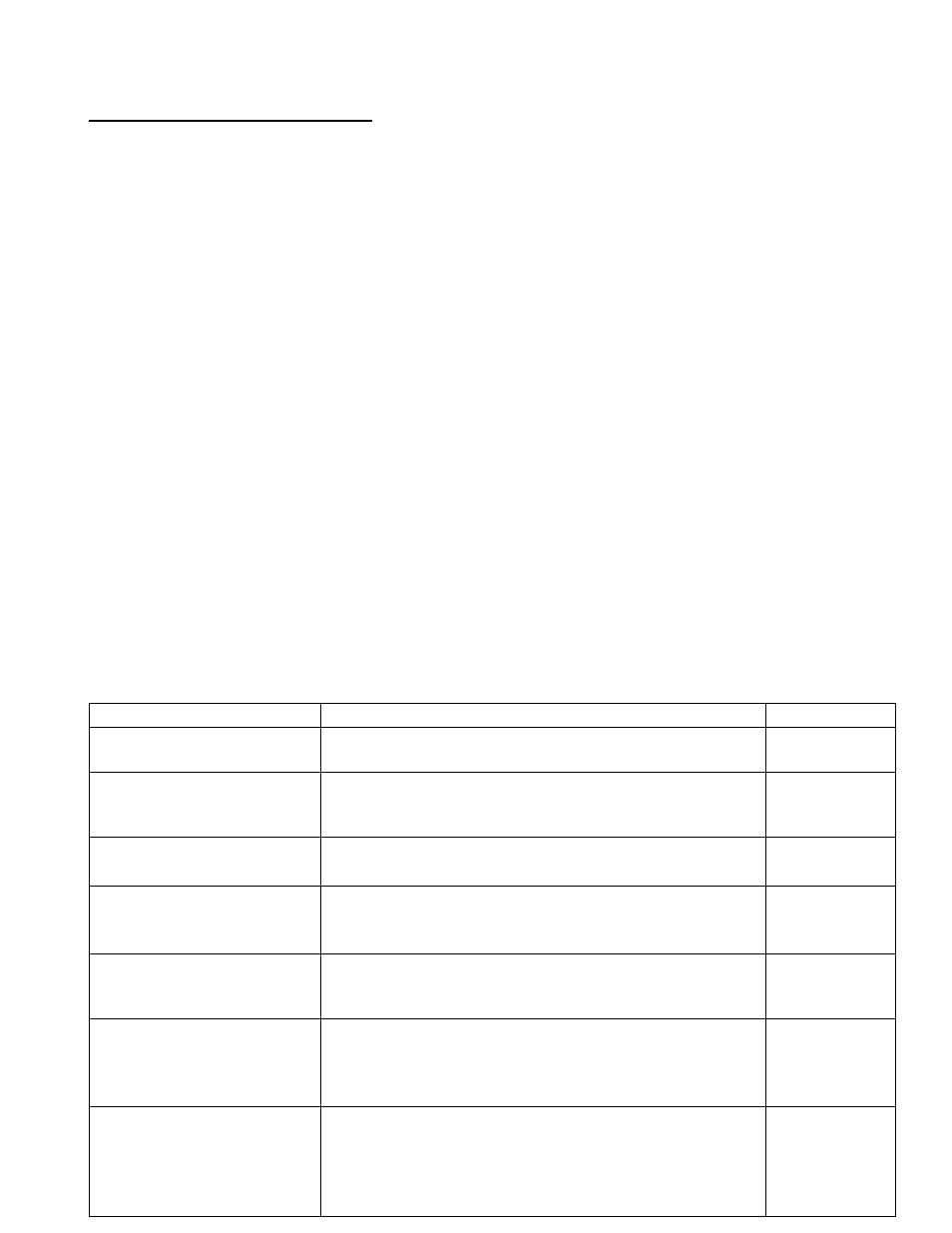

Table

2. Maintenance Schedule

Maintenance Required

Procedure

Frequency

Inspect/clean air filter.

Remove air fitter and inspect. Clean if required; replace.

NOTE:

Never operate air conditioner with filter removed.

Weekly

Inspect/clean air discharge

louvers, return air grille, and

electronic control.

Inspect air discharge louvers, return air grille, and electronic

control for dust and dirt accumulation. Clean, if necessary.

NOTE:

Inspect more often in dusty environments.

Weekly

Inspect louvers on outer case

for obstructions.

inspect louvers on outer case and remove any obstructions.

Monthly

1 nspect condenser coil.

Inspect condenser coil for dirt, bent fins, and other

obstructions. Clean/repair, if necessary.

NOTE:

Inspect more often in dusty environments.

Annually

Inspect evaporator coil.

Inspect evaporator coil for dirt, bent fins, and other

obstmctions. Clean/repair, if necessary.

NOTE:

Inspect more often in dusty environments.

Annually

Inspect outer case for

signs of damage.

Inspect interior and exterior of outer case for scratches,

paint blisters, rust, and other damage. Repair as necessary.

NOTE:

Inspect more often in salty or other corrosive

environments.

Annually

Inspect/clean base pan.

Inspect base pan for scratches, blisters, rust, dents, and other

damage. Repair as necessary. Clean condensate drain

passages of any accumulated material.

NOTE:

In areas of excessive humidity, use algicide (algae

inhibitor) in base pan to help reduce algae build-up.

Annually