Installation & maintenance instructions, Asco valves, Pc-series – CAMCORP Blower Package with Sutorbilt Blower User Manual

Page 59: Description, Installation

Page 1 of 4

50-60 Hanover Road, Florham Park, New Jersey 07932

ASCO Valves

e

MCMXCI All Rights Reserved.

Installation & Maintenance Instructions

PC-SERIES

Form No.P7050R1

SWITCH UNITS

OPEN-FRAME TYPE, GENERAL PURPOSE, OR WATERTIGHT SWITCH ENCLOSURE

TWO-STAGE FIXED DEADBAND SWITCH UNITS

DESCRIPTION

The PC-Series Two-Stage Fixed Deadband Switch Units are used with

transducer units to make Tripoint Pressure Switches or Temperature

Switches. The switch units are made of aluminum alloy and designed for

rugged use. The switch unit may be provided as open-frame type or with a

general purpose or watertight enclosure. All wiring terminals, adjustments,

and visual scales are accessible from the front of the switch.

The switch may be supplied as a complete unit, with the switch unit and

transducer unit completely assembled. The components may be separate

units to be assembled upon installation. The two-stage switch unit has two

adjusting nuts which provide independent adjustment of the two electrical

switches. Each switch has an adjustable (set) point and non-adjustable

(reset) point. The difference between the set point and the reset point is the

fixed deadband. The actuation points of the electrical switches cannot be

identical but require a minimum separation. The switch assembly can be

mated with a wide selection of pressure and temperature transducers to cover

a broad range of pressure, fluids, and temperatures. The switch will control

electrical circuits in response to change in pressure and temperature signals.

IMPORTANT: These instructions cover the installation and use of this

switch on pressure and temperature transducers. Select the paragraphs that

apply to your particular installation and application. The word signal is used

in place of pressure or temperature changes.

INSTALLATION

Check the nameplate for the correct catalog number, pressure range,

temperature range, media, and proof pressure or rated overrange temperaĆ

ture. Never apply incompatible fluids or exceed the pressure or temperature

rating of the switch. Installation and inspection to be performed by qualified

personnel.

Nameplates are located on the switch (or switch cover) and on the bottom of

the transducer. Check to be sure the third digit in each number is the same.

If not, the unit should not be used (Refer to Figure 4).

IMPORTANT: All internal adjustments have been made at the factory. Any

adjustment, alteration or repair to the internal parts of the switch other than

stated herein voids all warranties. The signal setting adjustments required

are made by the adjusting two nuts on the top of the switch.

Temperature Limitations

Switch ambient temperature limits are -4_F (-20_C) to 122_F (50_C). To

determine fluid temperature limitations, see Form No. P7051 for pressure

transducer catalog numbers and construction materials, then refer to chart

below.

TRANSDUCER

CONSTRUCTION MATERIALS

RATINGS

FLUID TEMPERATURE

Buna N or Neoprene

-4

_

F (-20

_

C) to 180

_

F (82

_

C)

VITON*

-4

_

F (-20

_

C) to 250

_

F (121

_

C)

316 Stainless Steel

-50

_

F (-45

_

C) to 300

_

F(149

_

C)

All Nylon

Maximum 180

_

F (82

_

C)

All Nylon

For Water Service

Maximum 130

_

F (55

_

C)

For stream service, the fluid temperature with a pigtail (siphon tube or

condensate loop) installed directly into the transducer will be below 180_F

(82_C).

Assembly Of Switch And Transducer Units

(Refer to Figure 4)

IMPORTANT: The switch unit and transducer unit may be purchased as a

complete assembly or as separate units. If separate units are purchased,

refer to Form No. P7051 for a complete listing of switch unit and transducer

unit combinations. Form No. P7051 is provided to ensure that the proper

switch unit is assembled to the proper transducer unit.

Pay careful attention to exploded view provided in Figure 4 for assembly of

switch unit and transducer unit. Proceed in the following manner:

CAUTION: The third digit in the catalog number on both the switch unit and

the transducer unit must be identical. If not, do not assemble to each other.

If the same, proceed.

1. Remove bolts (4) from base of switch unit. On general purpose or

raintight constructions, remove switch cover.

2. Remove instruction label and pressure or temperature switch range

scale from the transducer unit.

3. Place transducer unit on base of switch unit and assemble. Start bolts

(4) approximately two turns by hand to avoid the possibility of cross

threading. After initial engagement, torque bolts (4) in a crisscross

manner to 80±10 in-lbs [9,0± 1,1 Nm].

4. Remove backing paper from range scale and install on the front of the

switch body over the opening for the adjusting indicator point.

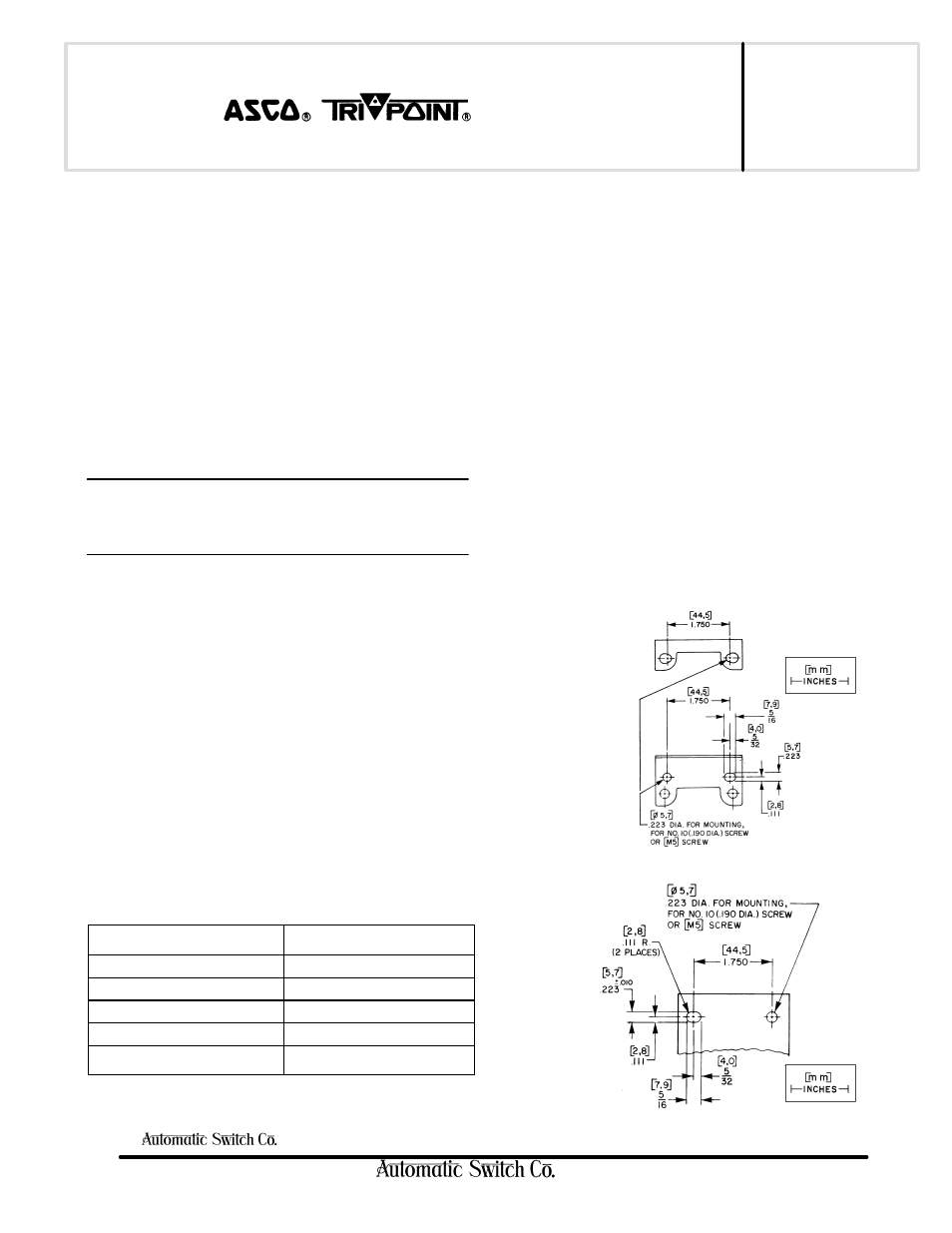

Positioning

Switch may be mounted in any position.

Mounting

Refer to Figures 1 and 2 for mounting.

Figure 2. General Purpose Enclosure

Figure 1. Optional Mounting Bracket