Rs 1942 – C&D Technologies RS-1942 L Series NEBS Compliant Racks User Manual

Page 2

RS 1942

TORQUE VALUES

Hardware Type

Torque Value

3/8”-16 Bolt, Nut and Lock Washer

15-20 Ft.-lbs (20-27 N•m)

1/2”-13 Bolt, Nut and Lock Washer

55-65 Ft.-lbs. (75-88 N•m)

3/8”-16 Bolt, Strut Nut and Lock Washer

19 Ft.-lbs. (25 N•m)

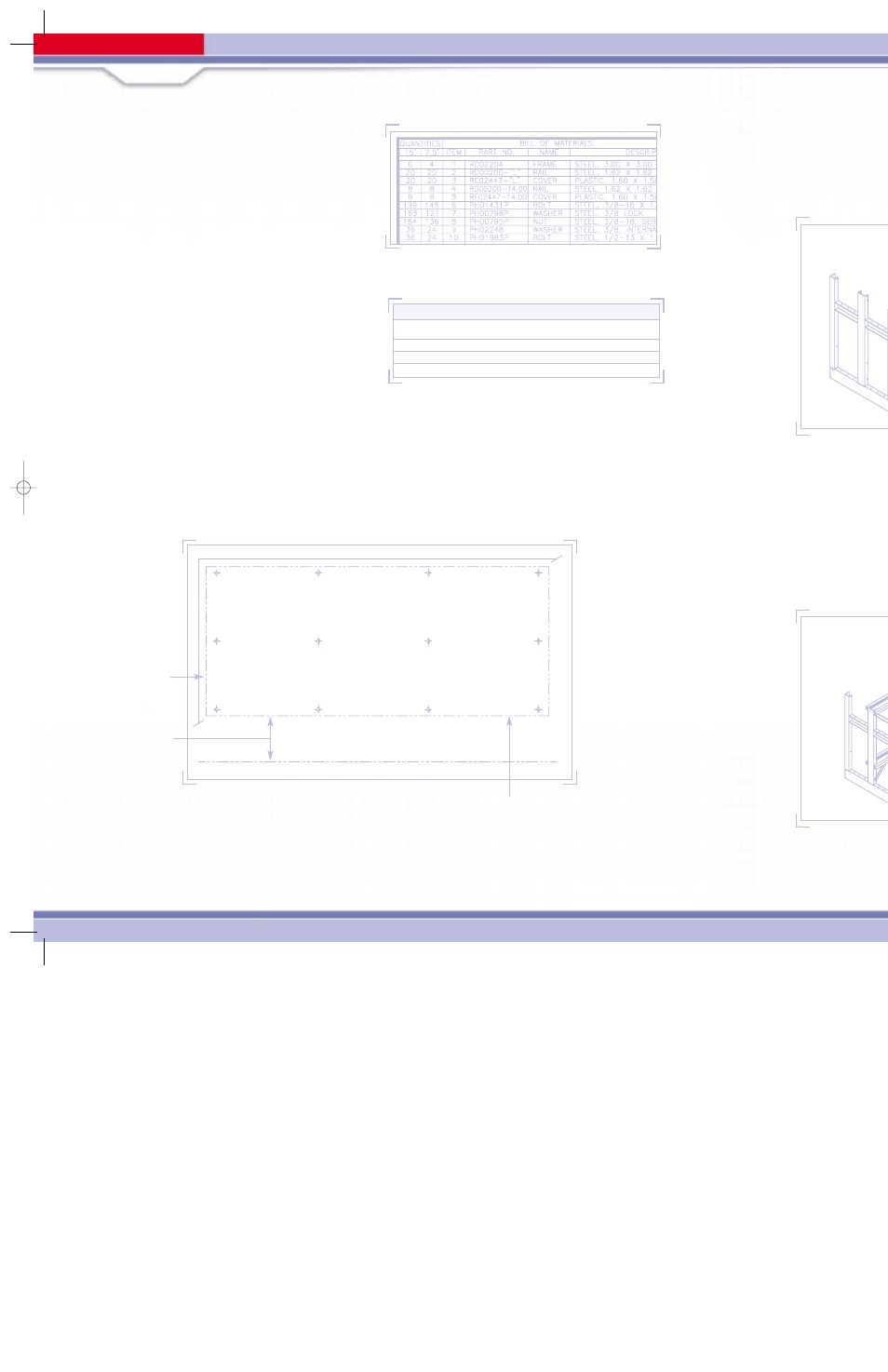

MATERIAL VERIFICATION

Battery racks are shipped unassembled with a complete

set of related drawings and documentation. Check received

parts and quantities against the rack’s Bill of Materials

(reference Table #1) on the provided drawing or packing list.

Do not assemble rack if parts are missing or quantities are

incomplete. Please contact C&D’s customer service,

800-543-8630 with any problems.

REQUIRED TOOLS

Torque wrench (0 to 120 ft.-lb.) with hex sockets for 3/8”

and 1/2” hardware. Adjustable wrench or 3/8” and 1/2” box

wrench, tape measure, square and leveling device.

Note: Consult manufacturers’ instructions for tools

required to install floor anchoring hardware.

INSTALLATION DETAILS

Bolted connection details are located at the end of

installation manual for reference. Torque values for

hardware are shown in Table #2.

LOCATION OF RACK

When determining the rack location and floor anchor pattern,

use applicable drawings provided with rack shipment.

Locate the racks’ general position, considering boundary

and aisle clearances. Locate floor anchoring locations

using provided drawings.

TABLE #1

Sample Bill of Material.

FIGURE #2

Rack Assembly Location and Anchor Bolt Pattern.

TABLE #2

Tourque Values.

Typical rack

clearance, 2 min.

Typical aisle

clearance, 36

External rack dimensions.

See assembly drawings.

FIGURE #3

Placing

FIGURE #5

Installin

1

Initial Assembly

not supplied with

(away from aisle)

rack drawing for p

brace to brace co

ASSEMBLY INSTR

2

Side Rails:

Insta

See Figure #5. R

Place support rail

properly engaged

3

Installing Suppo

on 2-tier/2-row ra

RSO1942 2/18/03 4:06 PM Page 2