Behlen 80110060YEL User Manual

Page 14

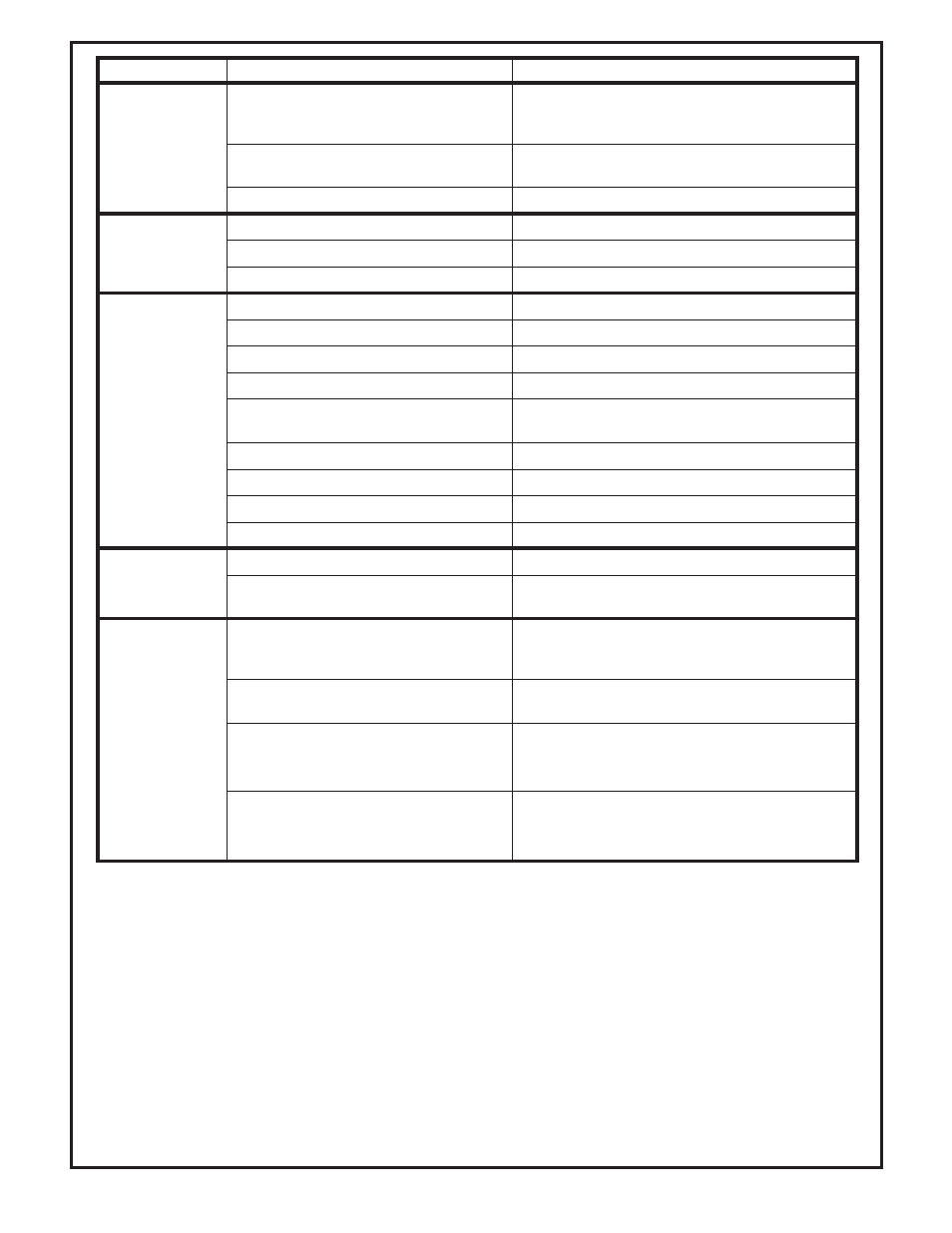

PROBLEM

POSSIBLE CAUSE

POSSIBLE REMEDY

Excessive

vibration

9. Drivelines not placed correctly.

Implement and tractor yokes must

be in line.

Replace driveline.

10. Wire or rope wrapped around blade

beam.

Remove wire or rope.

11. Blades worn and are out of balance.

Replace blades, in sets.

Gearbox

noisy

1. Rough gears.

Run in or change gears.

2. Worn bearings.

Replace bearings.

3. Low oil in gearbox.

Check level and add oil.

Gearbox

leaking

1. Damaged oil seal.

Replace seal.

2. Bent shaft.

Replace oil seal and shaft.

3. Shaft rough in oil seal area.

Replace or repair shaft.

4. Oil seal installed wrong.

Replace seal.

5. Oil seal not sealing in the housing.

Replace seal or use a sealant on outside

diameter of seal.

6. Oil level too high.

Drain oil to proper level.

7. Hole in gearbox.

Replace gearbox.

8. Gasket damaged.

Replace gasket.

9. Bolts loose.

Tighten bolts.

Excessive

wear of

tailwheel tire

1. Tire not turning properly.

Check wheel assembly for proper lubrication.

2. Tailwheel not castering properly.

Check tailwheel yoke assembly for proper

lubrication or for mechanical binding.

Front hitch “A”

frame bending

sideways

1. Operator turning sharply hitting

objects with tailwheel frame of

mower deck.

Drive carefully and plan turns to avoid hitting

buildings, posts, trees, etc.

2. Tailwheel not castering properly.

Check tailwheel yoke

(see above under tire wear).

3. Mower is being operated too low and

mower deck is contacting ground

during turns.

A. Raise mower (especially on rough ground)

B. Set stop on hitch controls lever so hitch lift

arms do not drop mower on ground.

4. Tractor 3 point hitch is leaking down

and mower deck is contacting

ground.

A. Repair tractor hitch hydraulic system.

B. Use limit chains to keep lift arms from going

lower than set limit.

F-20862

1-12-11