Adjusting label sensitivity – CON-TECH CS2000-QD User Manual

Page 12

- 10 -

Adjusting Label Sensitivity

Overview:

The CS2000 will automatically adjust its label sensitivity, to the optimal setting, by

simply depressing a push-button. This adjustment process is referred to as "Easy Setup." It is

recommended that the operator adjust the label sensitivity for each new roll of labels due to

differences in label rolls.

Easy Setup:

To adjust label sensitivity for each new roll of labels follow steps 1-4.

1. Peel off a label and position the web (label backing) under the sensing area.

2. Depress the push-button until the yellow LED comes on (1 sec.), then release.

3. The yellow LED will begin flashing.

4. Move a label under the sensing area and the green LED will come on.

The sensor is now adjusted and should function correctly.

*Note: If in the Adjusting Label Sensitivity mode by mistake, the push-button may be

depressed to exit with no changes made.

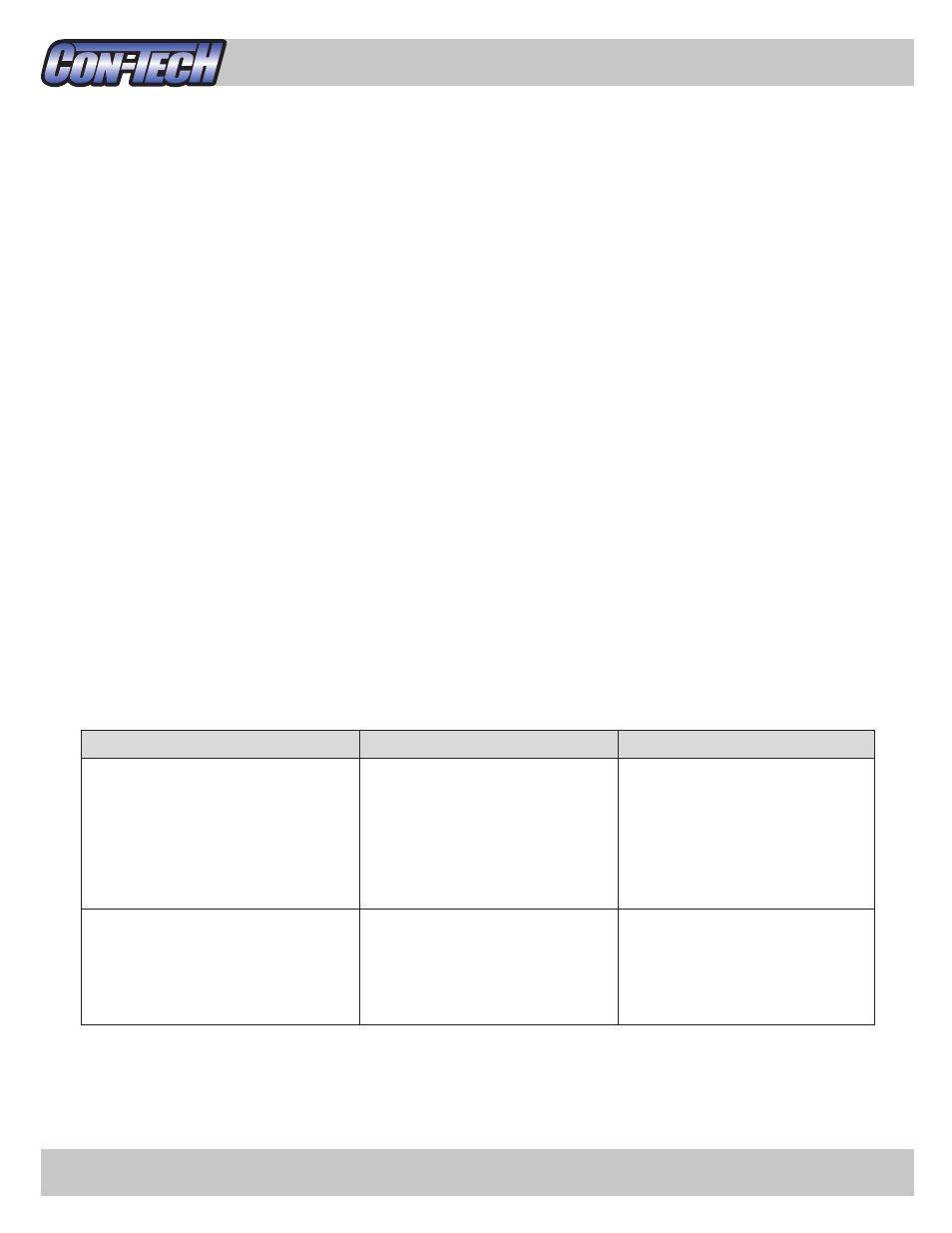

Possible Problems:

Red LED flashes after the

push-button is released.

The sensor cannot adjust

to the label backing.

Probable cause is a build

up of paper dust or some

other obstruction is under

the sensing area.

Blow out any paper dust

present and remove any

obstructions, labels, or

label residue from sensing

area (refer to page 15).

Symptom

Problem

Solution

Yellow LED continues flashing

even after a label is placed

under the sensing area.

There is not enough

contrast between the label

and the label backing.

Try the Low Contrast

Setting. See Program

Mode (page 12) for more

information.