Proper function. see sections, Maintenance and, Required inspec – FRITSCH PULVERISETTE 16 cast iron User Manual

Page 21: Tions, 6 maintenance, 7 required inspections

Page 20

PULVERISETTE 16

6 Maintenance

• Before the start of maintenance work, pull the power plug and se-

cure the device against accidental reactivation!

• Warn about maintenance work with a sign.

• Only have maintenance work performed by experts.

• Put safety devices back into operation after maintenance and repair

work.

The cross beater mill requires almost entirely no maintenance.

From time to time, the gap between the grinding insert and the impact plates

of the cross beater should be inspected.

Procedure:

• Pull the power plug

• Open the mill housing

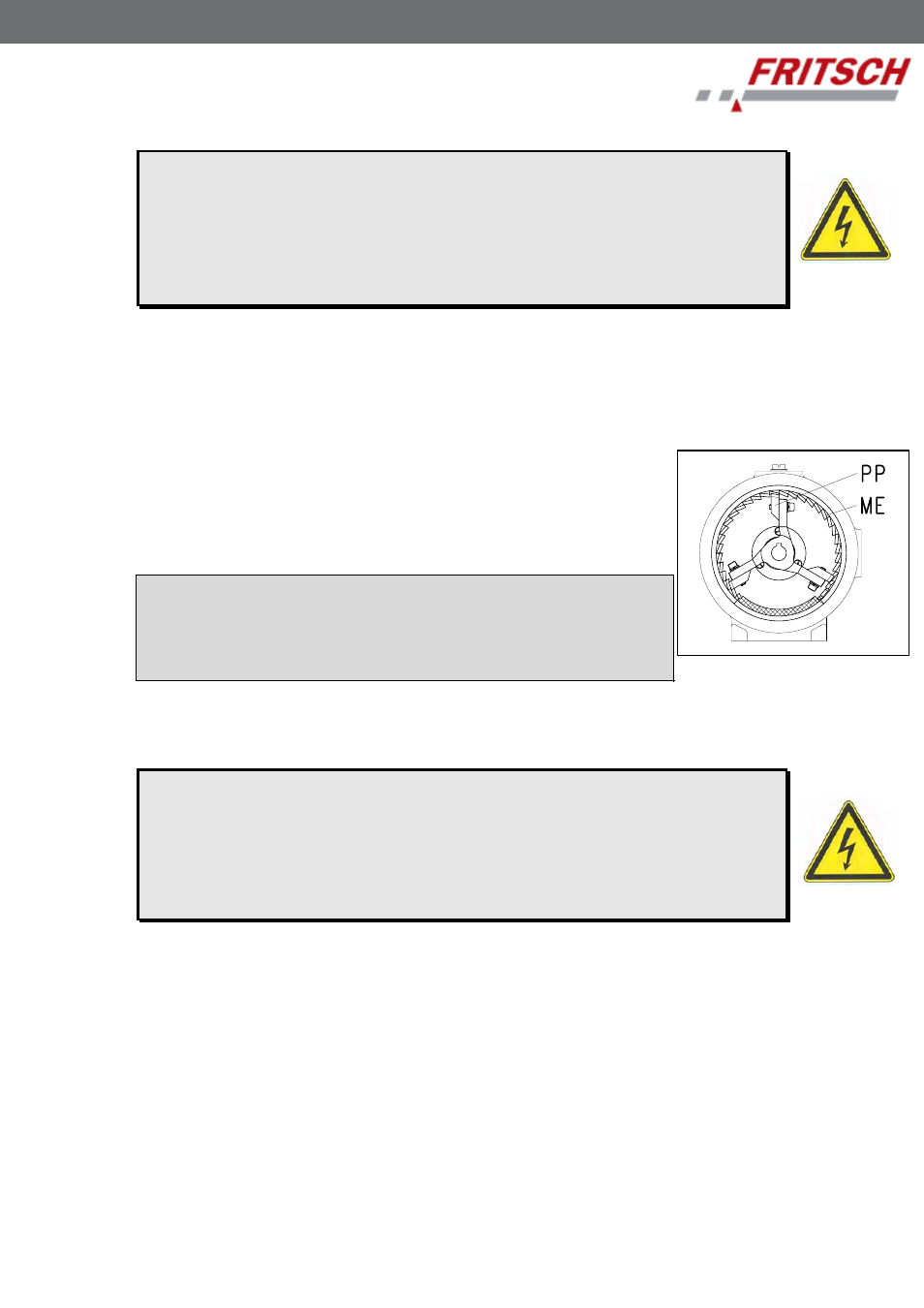

• Check the gap between the grinding insert ME and the

impact plate PP with a feeler gauge = desired value

1 mm, whereby the gap to the bottom sieve may not be

< 1 mm

Attention:

The gap between grinding insert and impact plate may by no

means exceed 2 mm since this can cause damages to the in-

strument.

• Adjust the gap between the grinding insert and impact plate, if necessary.

7 Required

inspections

• Before the start of repair work, pull the power plug and secure the

device against accidental reactivation!

• Warn about repair work with a sign.

• Put safety devices back into operation after maintenance and repair

work.

• Only have repair work performed by experts.

The limit switch and the motor brake should be tested for proper function

every six months.

• Limit switch on the door hinge on the left

o

With an opening gap of max. 3 mm, the limit switch must switch off the

motor

• Limit switch on quick latch on the right

o

Upon a rotation of the hand wheel of max. 45°, the motor brake must

be activated

• Motor

brake

o

Start

device

o

Stop

device

o

If the braking time exceeds 0.5 seconds, contact a service technician