5 cleaning, 7 readjusting the impact gap – FRITSCH PULVERISETTE 16 cast iron User Manual

Page 20

Page 19

PULVERISETTE 16

4.7 Readjusting the impact gap

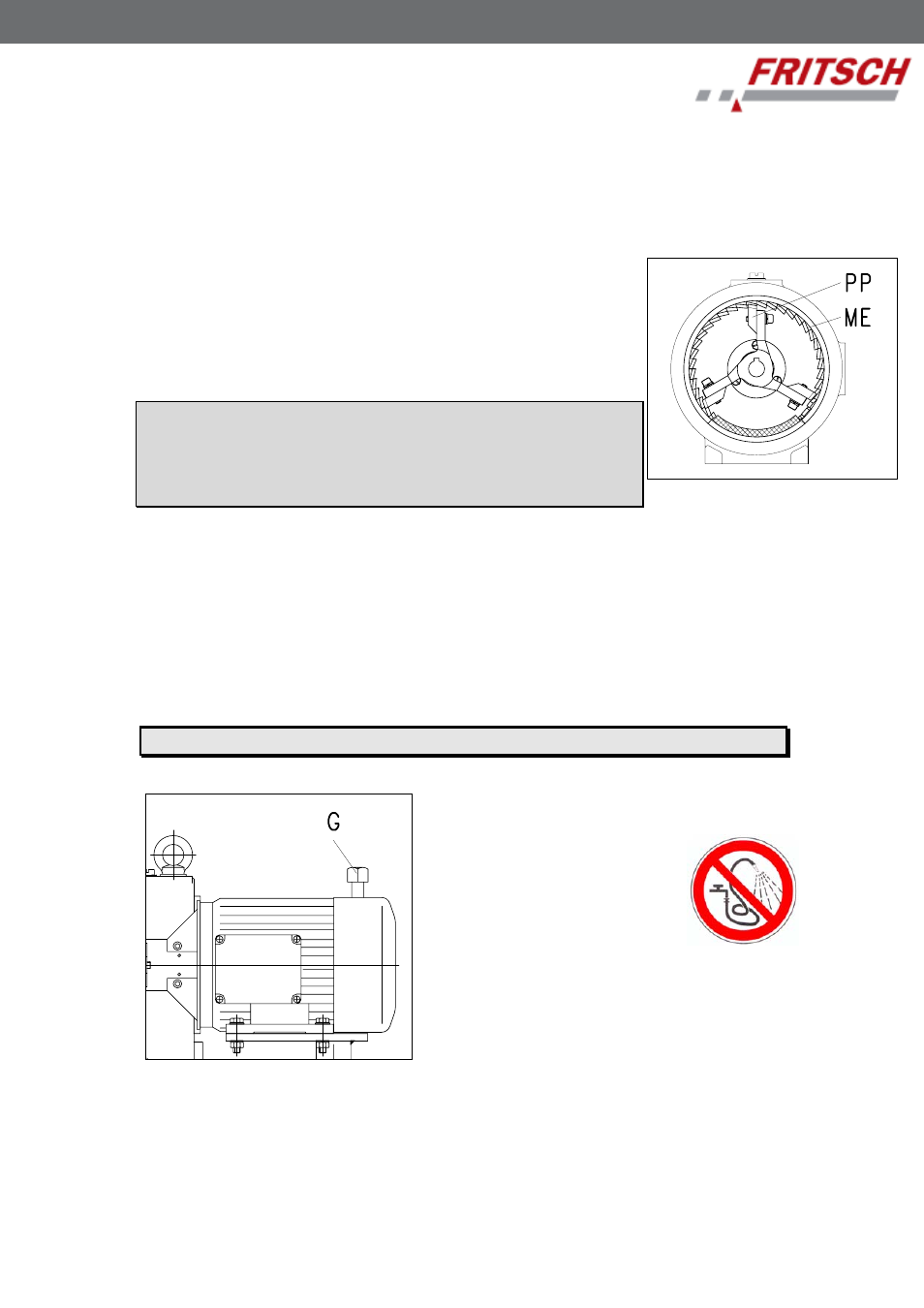

From time to time, the gap between the grinding insert and the impact plates

of the cross beater should be inspected. (See image)

• Pull the power plug

• Open the mill housing

• Check the gap between the grinding insert ME and the

impact plate PP with a feeler gauge = desired value

~ 1 mm, whereby the gap to the bottom sieve may not

be < 1 mm

Attention:

The gap between grinding insert and impact plate may by

no means exceed 2 mm since this can cause damages to

the instrument.

• Adjust the gap between the grinding insert and impact plate, if neces-

sary.

• * Screw the impact plates tight with a hex key M5

5 Cleaning

The cross beater mill can be cleaned while switched off using brushes, small

brushes and possibly vacuumed with an industrial vacuum cleaner or blown

off with compressed air.

Do not allow any liquids to flow into the device.

To clean the grinding chamber in the

cross beater mill

, the motor brake can be

released with lever G. The cross beater is easy to turn, making cleaning sim-

pler.

The protection class of the

cross beater mill

is IP54