Cylinder inspection – Cub Cadet T65 Series User Manual

Page 98

T65 Series Vertical Shaft Engines

92

Cylinder inspection

1.

Clean and inspect the cylinder, inside and out.

NOTE: If there is any sign of damage, especially

cracked cooling fins, short block the engine.

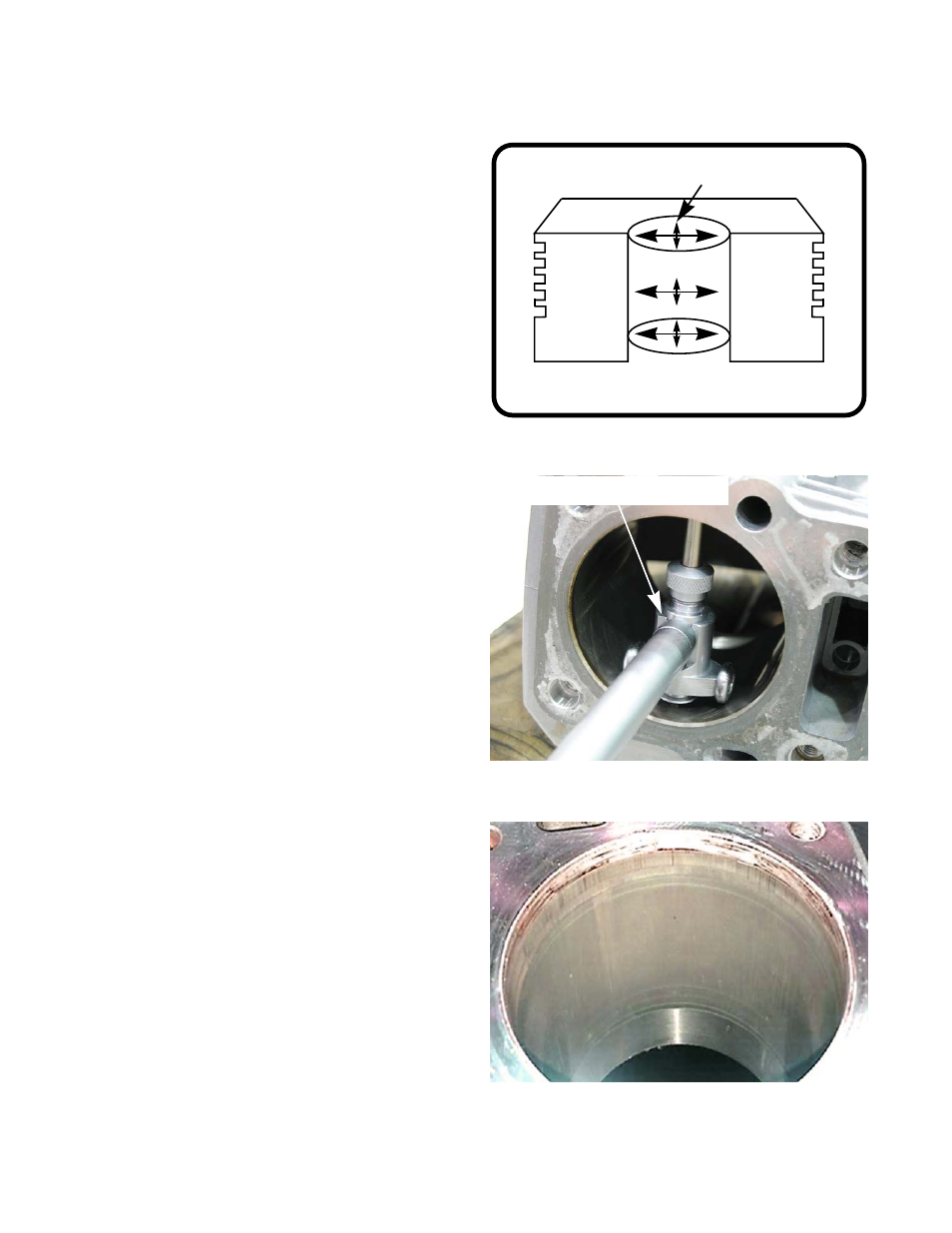

NOTE: Take two measurements of the cylinder bore

90 degrees apart at the top, bottom and mid-

dle of the cylinder. See Figure 10.17.

NOTE: The measurements can be made using tele-

scoping gauges, inside micrometers or a cyl-

inder bore dial indicator. See Figure 10.18.

2.

Compare the measurements to those that are listed

in the chart at the end of the chapter.

3.

Inspect the cylinder.

NOTE: The cylinder is manufactured using a special

machining process. This process does not

leave a cross hatch that is normally seen in

most engines. As the engine breaks in, the

cylinder will develop a smooth, dull finish.

See Figure 10.19.

NOTE: The cylinder may have some scratches. As

long as the scratches cannot be felt with a

finger nail, they are acceptable.

NOTE: If the cylinder needs to be de-glazed,

replace the cylinder block.

Figure 10.17

Measure the cylinder bore

Figure 10.18

cylinder bore dial indicator

Figure 10.19