Cub Cadet T65 Series User Manual

Page 109

Failure Analysis

105

3.

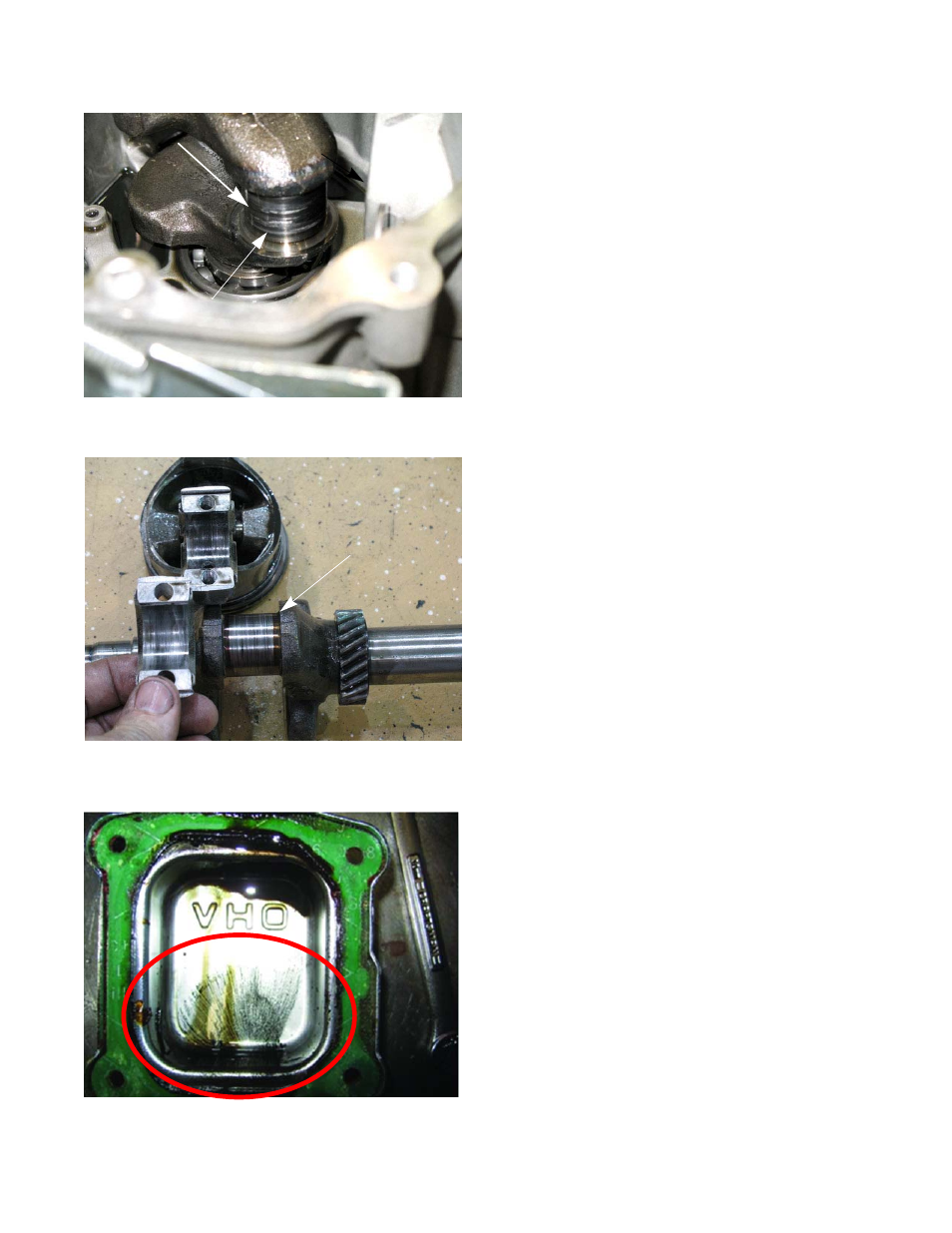

Metal transfer is the primary indicator that the film of

oil between two engine parts has been violated.

If the damage is localized, a general failure of the lubri-

cation system is probably not the cause.

As an example: a piston skirt shows metal transfer to

the cylinder wall. The connecting rod and wristpin show

some signs of excessive heat. The main bearings and

camshaft are not damaged. This would indicate that the

problem was probably related to cylinder temperature.

The hallmark of a lubrication failure is the presence of

discoloration and/or metal transfer on all of the friction sur-

faces within the engine. See Figure 11.7.

An important thing to note is that just because there are

signs of insufficient lubrication, that does not mean that

was the cause of the failure. It may only be a symptom of

the real cause of the failure.

Larger size abrasive particles can render the lubricants

ineffective, leading to an engine failure. An overheated

engine can cause the oil to break down leading to a failure.

In an engine overspeed, the oil is pushed away from the

bearing surface leading to a failure.

In all three of the above cases, the signs of insufficient

lubrication are symptoms not the cause. There will also be

signs of heat or discoloration around the parts affected by

the lack of lubrication. See Figure 11.8.

NOTE: When oil levels drop below a certain point, the oil

mist flowing up the push rod valley is not enough

to keep the oil return port full of oil. When this hap-

pens, the oil flow pattern reverses, creating a clam

shell like pattern on the inside of the valve cover.

This phenomenon is unique to MTD vertical shaft

engines. If there is a clam shell pattern, similar to

the one circled in Figure 11.9, the engine experi-

enced a lack of lubrication failure.

Figure 11.7

Metal to metal

transfer

Discoloration

Figure 11.8

Discoloration

Figure 11.9